Toyota Production System

Toyota Production System

Beyond Large-Scale Production

Taiichi Ohno

Foreword by Norman Bodek

Table of Contents

..... ix

.... xiii

.... xvii

.... xix

..... 1

The Oil Crisis Opened Our Eyes

Slow Growth Is Scary

"Catch Up with America"

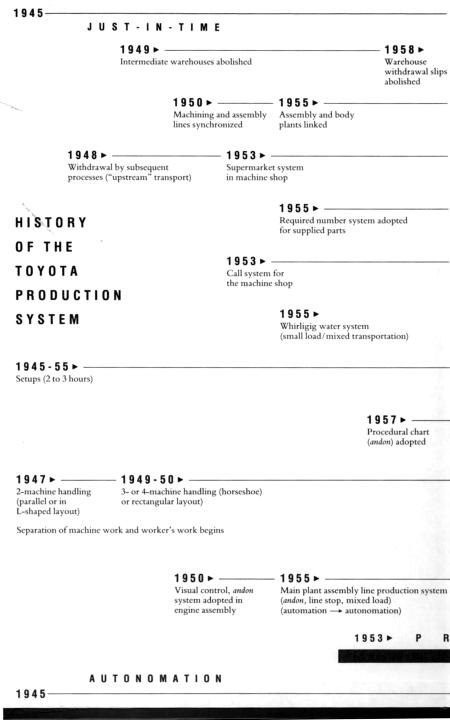

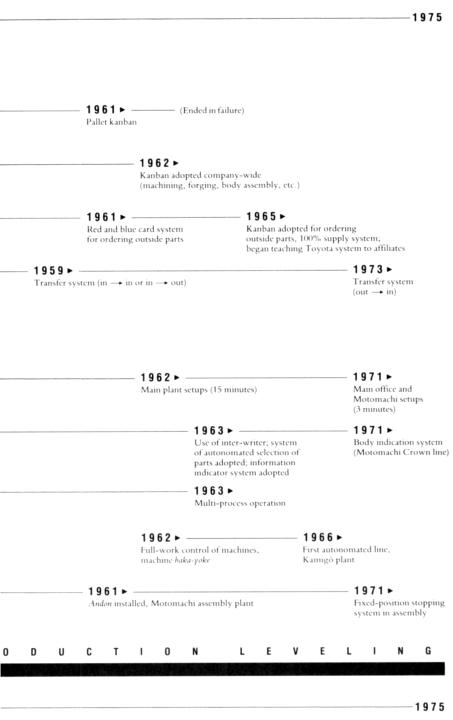

Just-In-Time

Using a Common-Sense Idea

Give the Machine Intelligence

The Power of Individual Skill and Teamwork

Cost Reduction Is the Goal

The Illusion ofJapanese Industry

Establishing a Production Flow

Production Leveling

In the Beginning, There Was Need

A Revolution in Consciousness Is Indispensable

.. 17

Repeating Why Five Times

Complete Analysis of Waste

My Plant-First Principle

Writing the Standard Work Sheet Yourself

Teamwork Is Everything

The Skill of Passing the Baton

An Idea from the U.S. Supermarket

What Is Kanban?

Incorrect Use Causes Problems

The Talent and Courage to Rethink What We Call Common Sense

Establishing the Flow Is the Basic Condition

Use Your Authority to Encourage Them

Mountains Should Be Low and Valleys Should Be Shallow

Challenge to Production Leveling

Production Leveling and Market Diversification

Kanban Accelerates Improvements

Carrying Carts as Kanban

The Elastic Nature of Kanban

An Autonomic Nervous System in the Business Organization

Provide Necessary Information When Needed

The Toyota-Style Information System

Fine Adjustment

Coping with Changes

What Is True Economy?

Re-Examining the Wrongs of Waste

Generate Excess Capacity

The Significance of Understanding

Utilizing the Full Work System

Do Not Make a False Show

Required Numbers Are All-Important

The Tortoise and the Hare

Take Good Care of Old Equipment

Look Straight at the Reality

0.1 Worker Is Still One Worker

Management by Ninjutsu

In an Art Form, Action Is Required

Advocating Profit-Making Industrial Engineering

Surviving the Slow-Growth Economy

. 75

A Global World Around Us

Two Extraordinary Characters

Learning from the Unyielding Spirit

Toyotaism with a Scientific and Rational Nature

Provide Good Equipment Even If the Factory Is Simple

Pursuit of a Japanese-Style Production Technique

Making Products That Have Value

A Chessplayer's View

In Search of Something Japanese

Witnessing a Dialectic Evolution

.. 93

The Ford System and the Toyota System

Small Lot Sizes and Quick Setup

The Foresight of Henry Ford

Standards Are Something to Set Up Yourself

Prevention Is Better than Healing

Is There a Ford after Ford?

Inverse Conception and Business Spirit

Getting Away from Quantity and Speed

... 111

The System Raised in the High-Growth Period

Raising Productivity During Low Growth

Learning from the Flexibility of Ancient People

.. 119

.... 121

...... 131

...... 135

....... 137

Publisher's Foreword

JUST AS WE have been recognizing the greatness of Mr. Shigeo Shingo, we also recognize the genius of Mr. Taiichi Ohno. It was Mr. Ohno who should be credited with the creation of the Toyota just-in-time production system.

I met Mr. Ohno in Japan at Toyoda Gosei where he became chairman after retiring from Toyota Motors. Toyoda Gosei is a Toyota subcontractor manufacturing steering wheels, automobile parts like rubber hoses and plastic dashboards, and other materials.

At our last meeting I asked him where Toyota was today in the improvement process. By now, the company must have reduced all work-in-process inventory - lowering the water level in the river to expose all the rocks, enabling them to chip away at all the problems.

"What is Toyota doing now?" I asked.

His answer was very simple.

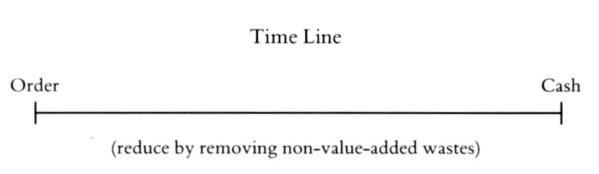

"All we are doing is looking at the time line," he said, "from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that time line by removing the non-value-added wastes."

Simple but brilliant. It gives a very clear focus to continuous improvement. Where we in the West would look immediately for some magic automatic miracle like computer integrated manufacturing (CIM), robotics, or advanced manufacturing techniques, the Japanese are simply reducing wastes. Of course, some wastes can be removed by acquiring new equipment but that should be done last - not first.

There is nothing very complex in the magic of Mr. Ohno's teachings. In fact, it is often confusing listening to him because he talks so simply, often just saying to look for and eliminate waste. We cannot believe that it is that simple - but it is true. Just reduce the time line by removing any wastes.

Mr. Ohno's simple tale told in the book is brilliant and should be read by managers everywhere. It is not just a tale of manufacturing, it is a tale of how to run a business successfully. Mr. Ohno went back and reviewed how Henry Ford ran his business. Henry Ford was able to mine iron ore on a Monday and, using that very same iron ore, produce a car coming off the assembly-line-on Thursday afternoon.

Henry Ford also focused on the total elimination of nonvalued-added wastes. Mr. Ohno just simply updated Henry Ford. He reduced changeover times with the help of Mr. Shingo from days and hours to minutes and seconds. He eliminated job classifications to give workers flexibility.