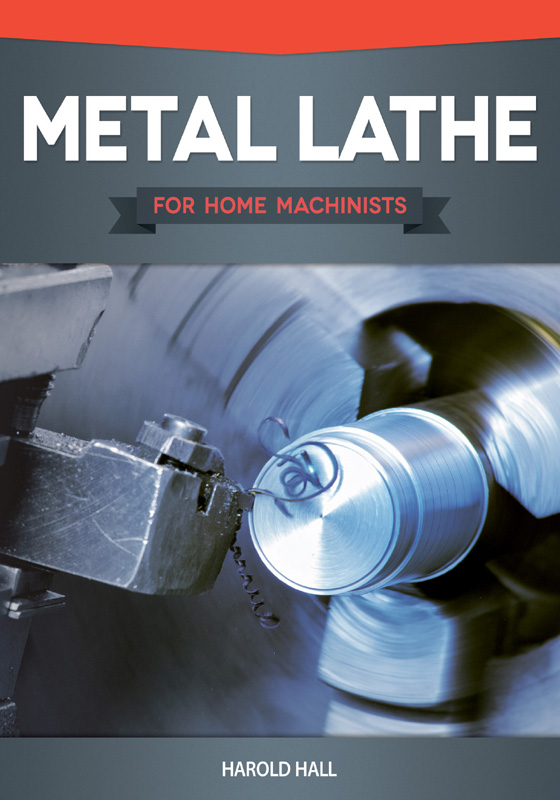

Harold Hall - Metal Lathe for Home Machinists

Here you can read online Harold Hall - Metal Lathe for Home Machinists full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2012, publisher: Fox Chapel Publishing Company Incorporated, genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Metal Lathe for Home Machinists

- Author:

- Publisher:Fox Chapel Publishing Company Incorporated

- Genre:

- Year:2012

- Rating:5 / 5

- Favourites:Add to favourites

- Your mark:

- 100

- 1

- 2

- 3

- 4

- 5

Metal Lathe for Home Machinists: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Metal Lathe for Home Machinists" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Metal Lathe for Home Machinists — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Metal Lathe for Home Machinists" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

2012 by Harold Hall and Fox Chapel Publishing Company, Inc., East Petersburg, PA.

First published in the United Kingdom by Special Interest Model Books, 2003.

First published in North America in 2012 by Fox Chapel Publishing, 1970 Broad Street,

East Petersburg, PA 17520.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission of the copyright holder.

eISBN 978-1-60765-143-7

ISBN 978-1-56523-693-6

Library of Congress Cataloging-in-Publication Data Hall, Harold, 1933

Metal lathe for home machinists / Harold Hall.

p. cm.

Includes index.

ISBN 978-1-56523-693-6

1. Models and modelmakingHandbooks, manuals, etc. 2. Turning (Lathe work)Amateurs manuals. 3. Metal-workAmateurs manuals. I. Title.

TT155.H26 2012

684.083dc23

2011040393

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free 800-457-9112 or visit us at www.FoxChapelPublishing.com.

Note to Authors: We are always looking for talented authors to write new books. Please send a brief letter describing your idea to Acquisition Editor, 1970 Broad Street, East Petersburg, PA 17520.

eBook Version 1.0

Because working with metal and other materials inherently includes the risk of injury and damage, this book cannot guarantee that following the instructions in this book is safe for everyone. For this reason, this book is sold without warranties or guarantees of any kind,expressed or implied, and the publisher and the authordisclaim any liability for any injuries, losses, or damages caused in any way by the content of this book or the readers use of the tools needed to complete the processes presented here. The publisher and the author urge all readers to thoroughly review each process and to understand the use of all tools before beginning any project.

CONTENTS

Preface

The main aim of this book is to take the newcomer to turning from the novice stage through to an experienced beginner, achieving this by providing a range of projects each one primarily illustrating a particular process. Finally the book concludes with two quite advanced projects that will put to the test the skills learnt in earlier chapters.

Having spent a short while as editor of Model Engineers Workshop, I am also aware that many have limited time for workshop activity and these, even if experienced, will find the projects useful as most can be completed in a matter of a few hours. No doubt, some useful tips being gleaned from the book on the way even for the experienced turner.

Whilst just reading the book will provide the beginner with much useful information this will be a poor substitute to actually making the items described. The reader is therefore encouraged to at least make most of the items detailed.

Removing metal using a metal work lathe is a straightforward process with quality work being easily achievable. However, the range of processes possible make the task of coming to terms with operating a lathe quite an extensive course that this book aims to provide.

Using a milling machine is on the other hand quite the reverse with obtaining a presentable finish much more of a problem but with each task being much more like others carried out on the machine. In this case the main requirement is to spend time on the machine to feel at home with its capabilities. A follow-up book to this will address the requirement with a range of projects aimed at giving the necessary time spent using the machine.

Harold Hall, 2003

Chapter 1

Getting started

Prior to getting to grips with the projects in this book some discussion regarding the lathe and the accessories that go with it is included for the newcomer to turning.

The Machines

Of course a lathe is a necessity, though for some this may initially be a machine available at the local technical college. If you are purchasing a lathe for the first time it is difficult to advise, as it will depend on the type of work envisaged and what other machines are to be acquired, two points are thought worth emphasising. First, if space and funds are available purchase a lathe of at least 90mm bed to centre height and secondly purchase a lathe with a tee slotted cross slide. The last point is a must if the workshop will not have a milling machine and even if it has many simple milling operations are easier to perform on the lathe as is illustrated in Chapter 13 Photos 14 and 15. However, as the projects are primarily aimed at those with limited experience it is assumed that other activities, typically milling, are even more of an unknown quantity. Their use in the series is therefore limited. A drilling machine will be required, but using the lathe for drilling as an alternative is briefly considered.

Whilst the use of cutting tools with replaceable tips considerably reduces the amount of grinding necessary to produce and sharpen lathe tools, some specials are bound to be required. An off hand grinder is therefore a necessity.

Chucks

Having dealt with the machines there is a number of accessories that are a must. It is easy to fall into the trap of considering that, due to its ease of use, a 3-jaw chuck is the one to acquire if funds will run to one chuck only, this is not so. Whilst a 3-jaw chuck, even if old and worn, will be accurate enough for most work there will be a significant number of instances where this is not so.

The beginner may not be aware that when material is placed into a 3-jaw chuck the work piece is unlikely to run true, perhaps a total indicator reading (TIR) of up to 0.1mm, more if measured some distance from the jaws. This can cause serious problems with concentricity when an item has to be removed and replaced, say to work from either end.

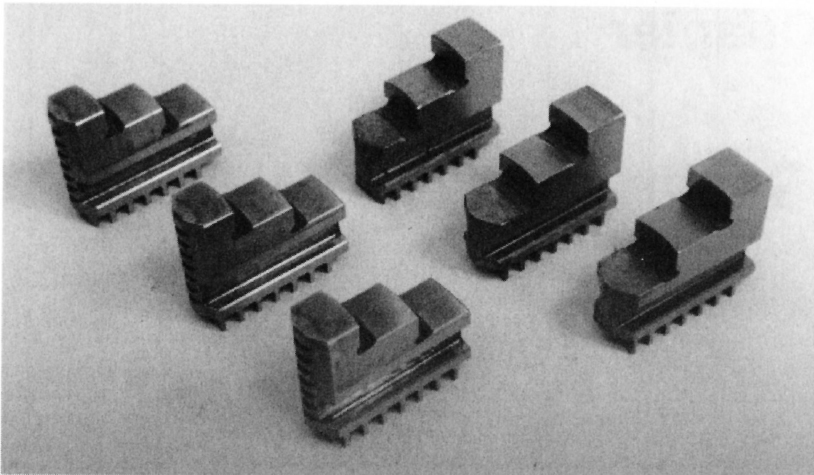

1. Normal (left) and Reverse (right) chuck Jaws.

Even a so-called precision chuck, with a price tag to go with the precision, will be unable to meet the most demanding requirements. A 4-jaw chuck with independent jaws is therefore a necessity as, being able to adjust each jaw individually, precise centring is possible. Of course where a 3-jaw chuck is adequate I will use one and this is evident in the photographs published. Where a reader has only a 4-jaw chuck this will be quite satisfactory. The only result being to slow down the operation a little due to the work necessary to get the part to run sufficiently true for the task in hand.

An essential accessory for the 3-jaw chuck are the reverse jaws that enable larger diameters to be held and are seen on the right of . A new chuck will always be supplied with these but if you have obtained a second hand chuck, maybe with a second hand lathe, they may well be missing. Unfortunately, spare jaws are not easily obtained and a replacement chuck may be the only option. One set of jaws will suffice for the 4-jaw chuck as its differing construction permits the single set of jaws to by used either way round.

Font size:

Interval:

Bookmark:

Similar books «Metal Lathe for Home Machinists»

Look at similar books to Metal Lathe for Home Machinists. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Metal Lathe for Home Machinists and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.