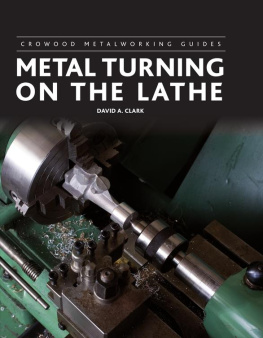

David A. Clark - Metal Turning on the Lathe (Crowood Metalworking Guides)

Here you can read online David A. Clark - Metal Turning on the Lathe (Crowood Metalworking Guides) full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2013, publisher: Crowood, genre: Children. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Metal Turning on the Lathe (Crowood Metalworking Guides)

- Author:

- Publisher:Crowood

- Genre:

- Year:2013

- Rating:4 / 5

- Favourites:Add to favourites

- Your mark:

- 80

- 1

- 2

- 3

- 4

- 5

Metal Turning on the Lathe (Crowood Metalworking Guides): summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Metal Turning on the Lathe (Crowood Metalworking Guides)" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Metal Turning on the Lathe (Crowood Metalworking Guides) — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Metal Turning on the Lathe (Crowood Metalworking Guides)" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

First published in 2013 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2013

The Crowood Press 2013

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 641 3

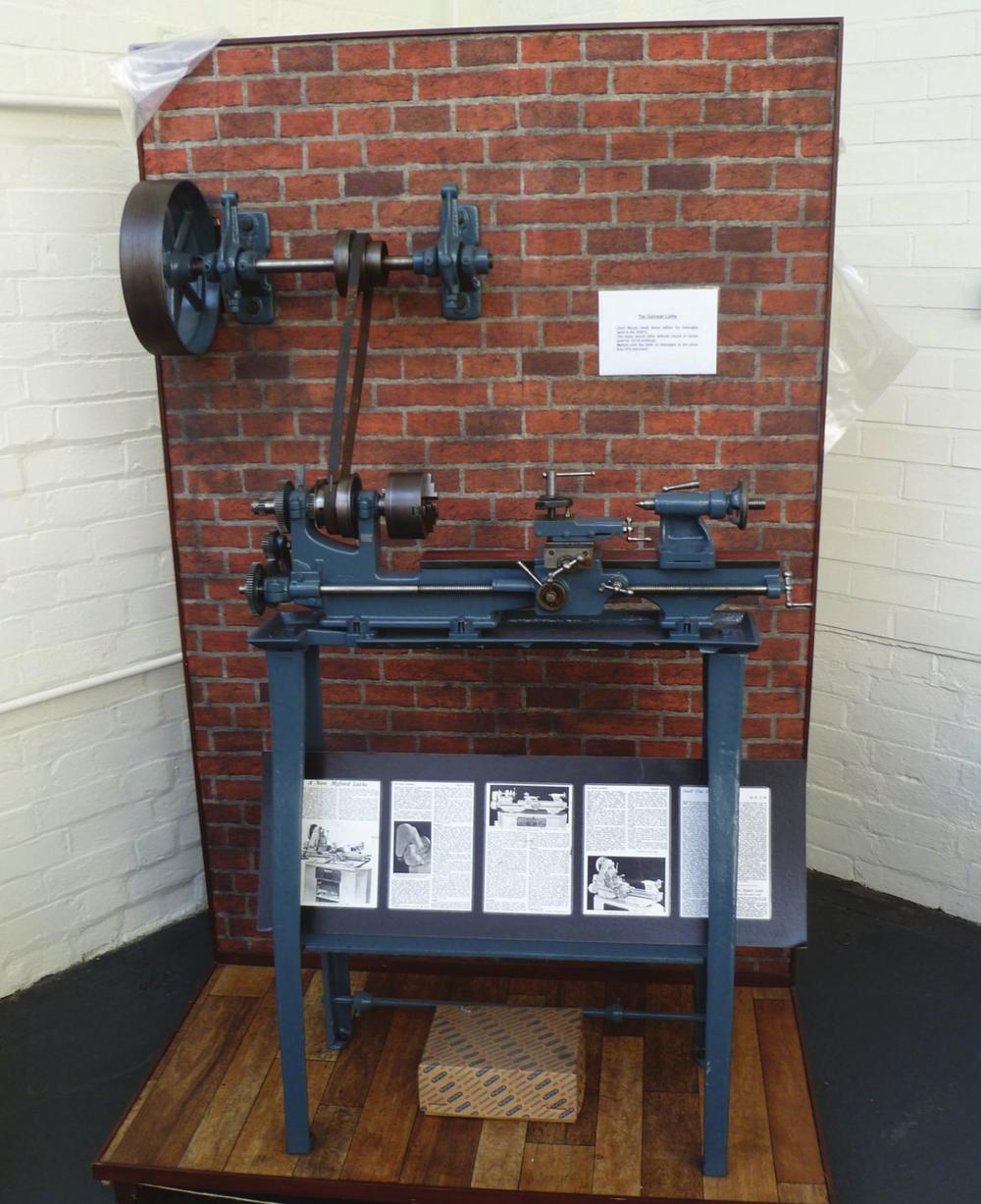

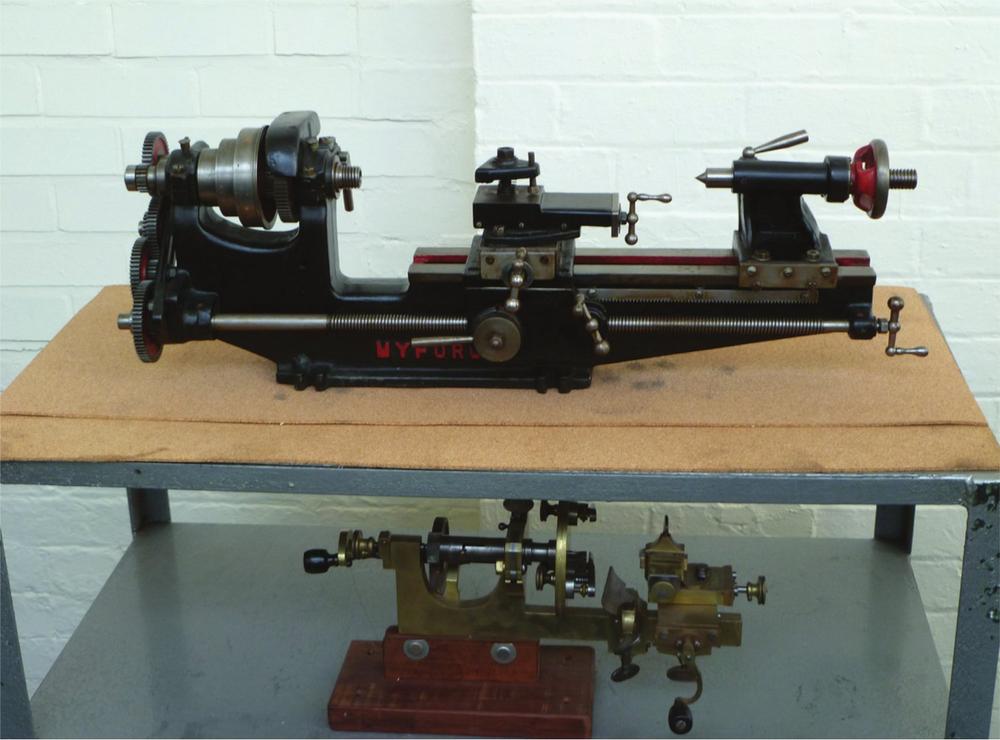

A Myford lathe dating from the mid-twentieth century, as supplied to Gamages, a London department store.

The lathe is often called the King of machine tools. It is very versatile and can be used to make all sorts of engineering components . Henry Maudslay, who made his first screwcutting and metal-working lathe in England shortly before 1800, was one of the first engineers to incorporate the slide rest, a leadscrew and change gears into one machine. This made it possible to make interchangeable screw threads, which, in turn, revolutionized the production of machines and machine tools.

This book is for you, the practising or aspiring engineer. Whether you are working in an industrial environment or a home workshop, this book will help you to acquire important new skills and give you insider tips you wont find elsewhere.

Perhaps you dont have a knowledgeable friend to teach you or you arent able to join a club. It does not matter what previous experience you have, this book will teach you the basics of lathe work from first principles to advanced turning techniques. You will find all you need to know within these pages.

During more than thirty years in the engineering industry I have worked with many engineers, both beginners and experts, and have taught many young people during their first steps into engineering. Working as a self-employed engineer, I learnt quick and accurate ways of working, both from my own experience and from other engineers. Since 2008 I have edited Model Engineer and Model Engineers Workshop, the two main UK magazines for machining in the home workshop, and this has given me an insight into what amateur (and sometimes professional) engineers are looking for. I have also been able to advise many amateur engineers on how to solve their workshop problems or just to get them started on the right lines.

Model Engineers Workshop, introduced in 1990, is a relative newcomer to the model engineering scene. It deals mainly with tools and processes and is now published every four weeks.

Model Engineer, which currently appears every fortnight, has been published continuously since 1898. It is mainly about making precision models but often includes techniques for turning in the lathe.

I would like to pass on some of this knowledge . This book, Metal Turning on the Lathe, is the first of three for Crowood Press on aspects of workshop engineering; it will be followed by Milling and Introduction to Workshop Tools and Techniques. Each book will be a comprehensive guide for both the amateur and professional engineer.

A lathe is essential to all but the most basic of workshops. It enables you to produce turned components to a high degree of accuracy with the minimum of effort.

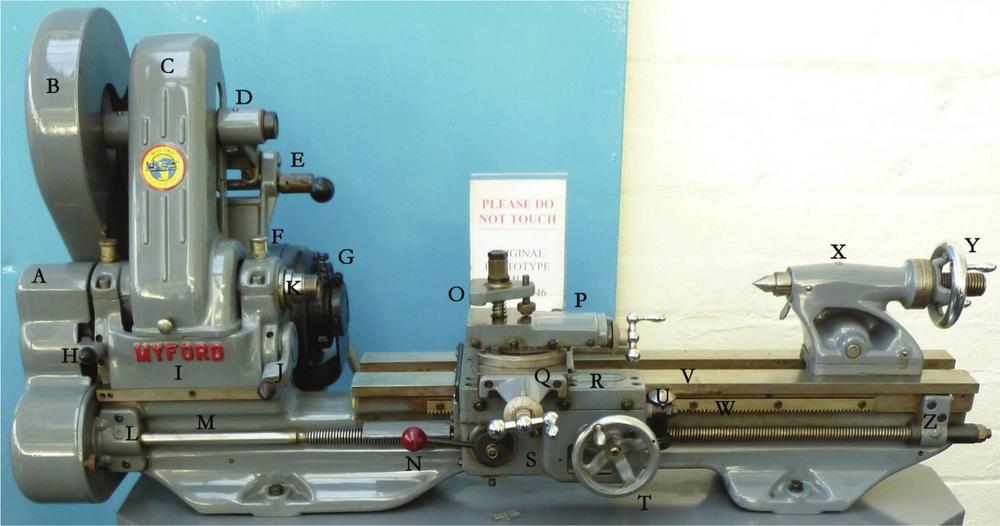

The basic Myford model, the ML7, was manufactured for many years. Tens of thousands are still to be found in garages, factories and home workshops around the world. This is the prototype ML7 Lathe as rebuilt by Myford Ltd.

The later ML7R and Super 7 models were fitted with a clutch as standard. This saves wear and tear on the electrical components and the motor. They also had more speeds. Later versions of the Super 7 can be found with a power cross feed. The illustration shows the prototype Super 7 lathe; again it has been rebuilt to factory standards by Myford Ltd.

The A to Z of a lathe: (A) Change wheel guard; (B) Countershaft pulley guard; (C) Drive belt guard; (D) Countershaft; (E) Belt tension lever; (F) Oiler; (G) Motor; (H) Tumbler gear operating lever; (I) Headstock; (J) Back gear operating lever; (K) Mandrel nose; (L) Left-hand leadscrew bearing; (M) Leadscrew; (N) Half nut operating lever; (O) Tool clamp; (P) Top slide; (Q) Cross slide; (R) Saddle; (S) Apron; (T) Carriage handwheel; (U) Screw thread indicator; (V) Lathe bed; (W) Rack; (X) Tailstock; (Y) Tailstock handwheel; (Z) Right-hand leadscrew bearing.

An early Myford lathe. Although very basic, it can do a lot of useful work in the workshop, especially if time is spent on making a few simple accessories.

.

of this book is about choosing a lathe, what size of lathe to buy, the different types available, desirable features, and whether you should buy new or second-hand.

covers installing a lathe, how to lubricate it and maintain it in good condition , and advice on general safety in your workshop with particular emphasis on how to use a lathe safely.

will look at the materials from which cutting tools are made, as well as their basic shape and geometry. Then we will look at selecting suitable speeds and feeds.

deals with sharpening lathe tools and how to set them up in the lathe.

covers the different types of chucks, how to use them and set work up accurately in them.

teaches you basic turning between centres and then introduces turning with the work mounted on the lathe faceplate.

is about holding work in a collet, and how you can make and use several different types of mandrel for workholding .

explains how to turn a taper using the top slide, the use of fixed and travelling steadies and making a form tool.

explains how to use drills and reamers in the lathe, including how to select the correct speeds and feeds.

shows the different ways to bore holes in the lathe: with the work held in a chuck, mounted on the faceplate or held on the cross slide.

explains how to use knurling tools and radius turning tools, as well as making simple form tools and basic production methods.

shows you how to use taps and dies to cut internal and external threads in the lathe. It also explains how to set up a simple gear train and cut a screw thread with the help of a screwcutting dial indicator .

Font size:

Interval:

Bookmark:

Similar books «Metal Turning on the Lathe (Crowood Metalworking Guides)»

Look at similar books to Metal Turning on the Lathe (Crowood Metalworking Guides). We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Metal Turning on the Lathe (Crowood Metalworking Guides) and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.