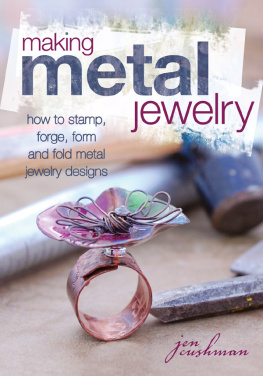

Making Metal Jewelry

HOW TO STAMP, FORGE, FORM AND FOLD METAL JEWELRY DESIGNS

Jen Cushman

Cincinnati, Ohio

The Thrill of MetalMy Story

My first encounter with metalsmithing was in 2005 at a national art retreat with mixed-media artist and metalsmith Susan Lenart Kazmer. I had been making jewelry as a hobby since I was a teenager, so when Susans description listed it as an intermediate-level class, I was sure I had the skills. Holy cow was I mistaken. During class I felt akin to Dorothy when she cried, Toto, I dont think were in Kansas any longer!

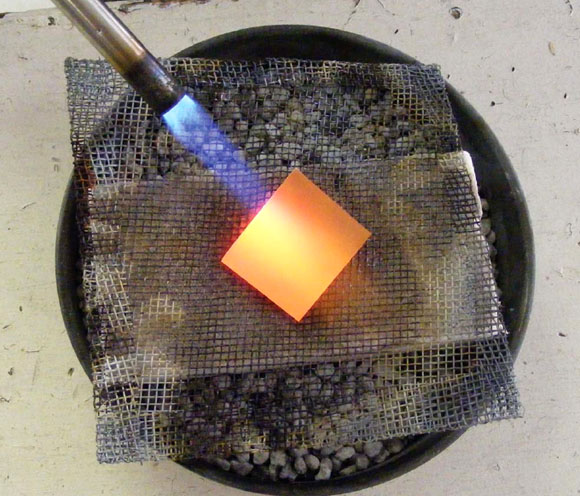

I struggled that day with my basic skills, but there was also something magical that happened. Students were lined up with fistfuls of wire in hand, patiently waiting their turns at the torches to draw a bead on the ends of their wire. The moment I dipped into that blue flame and watched the wire ball up and roll in on itself, was, literally, the minute my creative life changed. I felt like a bolt of lightning hit me between the eyes and all I wanted was to learn more. (I was fortunate to join Susan in 2009 as a business partner, and she continues to inspire me with her innovative techniques.)

After that art-retreat class, I bought a plumbers torch, sheet metal and wire from the hardware store and went home to practice my new skills. I scoured bookstores for a beginning metalsmithing book, but all I found were books overly detailed for my beginning needs.

I registered for a silversmithing class at my local community college. My instructor was a third-generation goldsmith, and I never once doubted his educational and professional credentials. As Ive learned to work metal, his precision and perfectionism still boggle my mind.

On my first day of class, I was instructed to make a bezel-set ring. I struggled with the jewelers saw, snapping one thin blade after another. I was so frustrated during my third class that I must have let out a long, loud sigh, and my professor inquired as to what was wrong. At my wits end, I said, This just isnt any fun. He looked me squarely in the eye and dryly replied, Making jewelry is not fun.

I was stunned into silence. I packed my tools and left my college class that day wondering if I should give up and return to my first loves of mixed-media paper crafting and collage.

Sheer tenacity kept me from quitting, however and I finished up the semester making three ugly bezel-set rings with semiprecious stones and a fairly decent bracelet.

With these experiences, I bet youre wondering why I would ever wish to write a book on making metal jewelry. The reason is simple: Manipulating metal stirs my soul with a sense of wonder and awe. Shaping, forming, annealing, forging and folding a solid piece of metal is not only fun, its downright thrilling!

I have one simple goal for this book: I want metalworking to bring you the same joy that it brings me. Im not a master metalsmith or studio jeweler by any means. While I have definitely learned the right way, meaning the safe way, to do certain techniquessuch as working with fire or using chemicals, and I will keep safety in mind throughout this bookthis book is written for other creative people, like myself, who want to explore metals potential and do so in their own way.

SECTION 1

Metal Fundamentals

When I first started learning about metalworking, I wanted to jump right in and build complicated pieces that were a little over my head for my skills at the time. Its just the type of artist I amalways wanting to go from 0 to 100 in under 60 seconds. Its my hope that the information in this book will save you not only time, but the costly mistakes that I learned the hard way. Before we jump right into the projectswhich I know you really, really want to dolets first spend some time reviewing metalworking fundamentals. In this section, youll learn about types and gauges of metals, necessary tools for metalworking and basic techniques that youll turn to time and again for making metal jewelry.

Types of Metal

When first learning about metalsmithing, its helpful to look at a piece of jewelry you admire and study the individual components of the piece. Even the most detailed and layered work can be analyzed and broken down to jewelry basics when you know what they are.

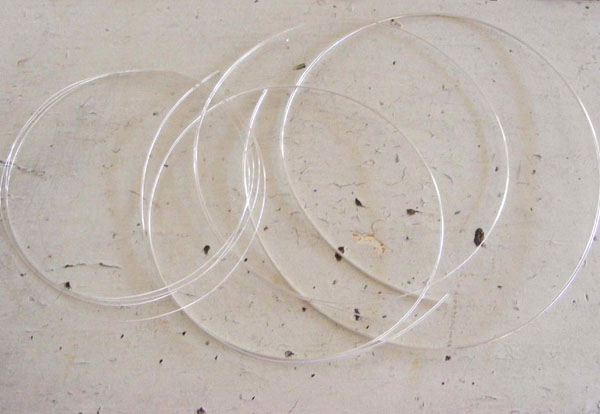

At its most fundamental, metal jewelry begins with either metal sheet or wire. As you go through this book, you will see these are the starting points for all twenty-two projects. Take note, as this simple principle will help tremendously as you continue to learn new techniques to manipulate metal and build beautiful jewelry.

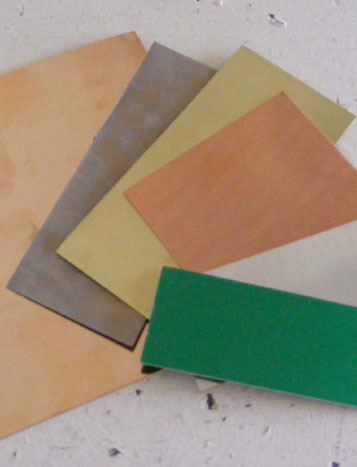

Sterling silver, which is an alloy (or mixture) of silver and copper, is the metal most jewelers prefer to work with because not only is it a gorgeous-looking white metal, but its smooth and malleable. The price of metals, and in particular sterling silver, has risen tremendously in the past few years, which means many artists are again turning to base metals: copper, brass, aluminum and nickel silver. In addition to sterling silver, my other favorite metal to use is bronze, which is an alloy of copper and tin. Not only is it inexpensive compared to sterling silver, it patinas beautifully and wears well. I adore the contrasting look of mixed metals, which is why you will see all of these metals used. Also, because of the way the projects are done, feel free to switch up the metal in the designs. Just because my projects instructions calls for bronze or sterling silver doesnt mean you have to use it, too.

Metal sheet and wire are sold in gauges, with the most common unit of measure being the Brown and Sharpe (aka, the B&S) gauge. When ordering from jewelry-supply stores, youll need to be familiar with this system because its how youll buy your metals. The higher the B&S number, the thinner the gauge; therefore, a wire gauge of 8 is a much heavier, thicker piece of metal than a 22-gauge.