LASER CUTTING AND 3-D PRINTING

FOR RAILWAY MODELLERS

LASER CUTTING AND 3-D PRINTING

FOR RAILWAY MODELLERS

BOB GLEDHILL

THE CROWOOD PRESS

First published in 2016 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2016

Bob Gledhill 2016

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 227 4

Disclaimer

The author and the publisher do not accept any responsibility in any manner whatsoever for any error or omission, or any loss, damage, injury, adverse outcome, or liability of any kind incurred as a result of the use of any of the information contained in this book, or reliance upon it. If in doubt about any aspect of laser cutting, 3-D printing and railway modelling, readers are advised to seek professional advice.

Acknowledgements

My thanks to those members of Manchester Model Railway Society who were the first to see and try out the first few chapters on their improvement course, and to Ralph Robertson in particular who gave me detailed feedback and many helpful comments after reading the entire script.

I would also like to express my gratitude to Ken Shipley for his help and support in the early stages of writing Part II: Laser Cutting. Finally my thanks to my wife, who has had to endure a winter of discussion on writing and chapter headings instead of the usual chat about what I have just made. Her support and proof reading have been invaluable.

CONTENTS

PREFACE

I have always been fascinated by technology, and sometimes a technology comes along that will change the way we work. Thus it was that in 1983, I bought a second-hand Sinclair ZX81 and started to learn how to program it and find out what it could do. Now computers are part of everyday life, but back then this was a marvellous and novel little machine. There were several computer magazines that had in them printed programs for games you could type into your computer and then play. Many didnt work the first time, and most of the fun was trying to de-bug the instructions and get them to work.

I returned to 4mm-scale (or strictly speaking 00-scale) railway modelling when I retired, having had a Triang TT layout in my youth, and found it an absorbing hobby with so many different skills to be learnt and models to be made. As you can imagine from the above, I quickly embraced DCC and computer control (via an ESU ECos controller and the excellent Traincontroller program).

I then met a member of the G-scale group, who meet at Keighley Model Railway Club, and joined, so now also have a G-scale garden layout. You will see examples of both scales throughout the book.

One of the members brought a cardboard tree, cut out on his wifes Craft Robo Cut machine. Thinking this might help with the making of cardboard buildings I did a search of the internet for cutting machine, and among the listings was a laser cutting/engraving machine.

Once I discovered I could actually purchase and own a laser cutting machine, and from a company only four miles away, I became really excited again! The prospect of being able to draw and design something on the computer screen and then actually cut it out to sub-mm precision was a thrilling prospect. Not only could I hope to produce professional-looking items, but I could produce them in quantity.

For me, learning CAD (computer-aided design) was done on an adrenalin rush of excitement and anticipation. I bought CorelDraw and spent many enjoyable hours learning how to use it, laser cutting items as I did so.

My greatest reward was in discovering the techniques required to enable me to laser engrave realistic-looking stonework on to ordinary mount card. I could make realistic Northern-looking stone-built houses, retaining walls and so on, without having to use paint or plastic sheet. Not only that, but as a bonus, the laser-engraving technique gave the surface a textured finish. The output might not have been finescale, but it was certainly better than anything I could have produced by painting plastic sheet.

More recently, and for over twelve months, I absorbed the news of each new 3-D printer with growing anticipation and excitement. I sent off for samples, read reviews, and eventually took the plunge and bought a Makerbot Replicator2. This proved to be a good starter machine, as Makerbot had made the printer driver software very user-friendly, and the machine itself worked without too many problems.

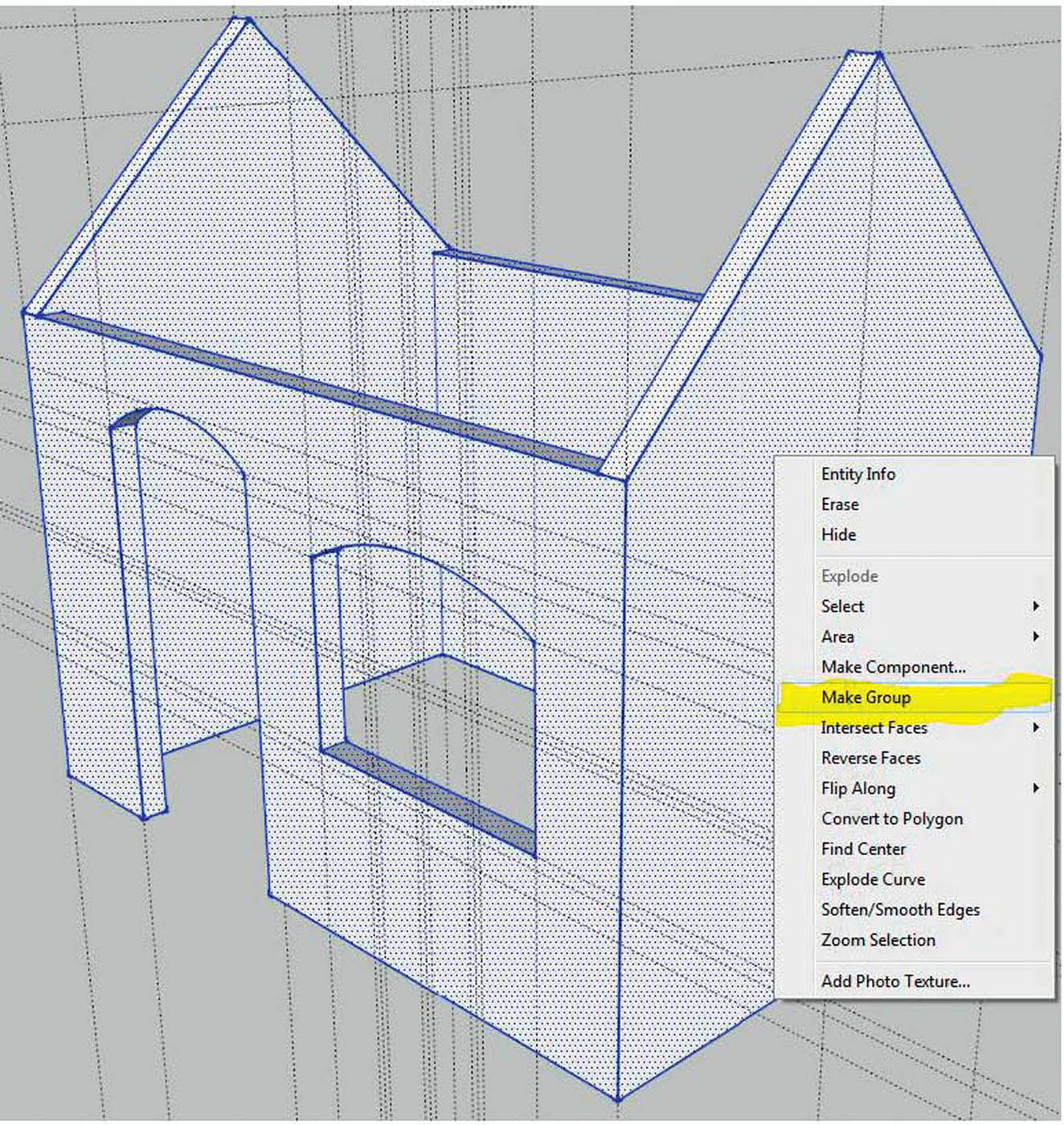

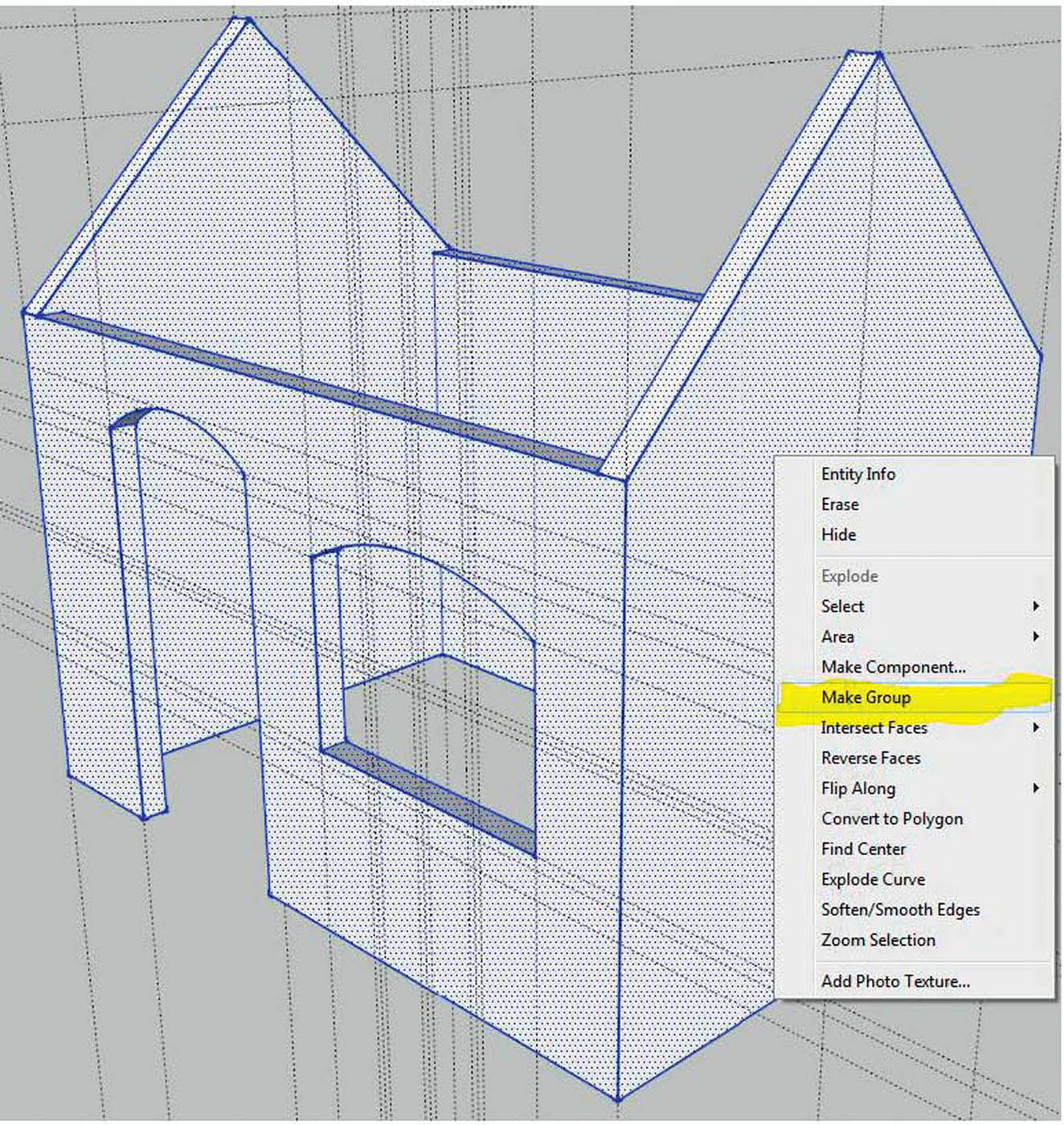

Whilst looking at these machines and deciding when to buy one, I realized that CorelDraw would not cope with 3-D drawing, so I downloaded trial versions of about six different 3-D drawing programs and tried each one for a couple of hours. I chose Sketchup as the program I seemed to get on best with. It is very different in the way it works to CorelDraw, even though many of the concepts are the same (drawing rectangles, circles, straight lines and specifying dimensions). It also had the advantage that the Sketchup Make version of the program was and still is at the time of writing free.

I have therefore chosen to use Sketchup Make as the CAD package in this book, and which is therefore illustrated the most, but the reader needs to be aware that there are other programs around, some of which may better suit your learning style. This one program will produce both 2-D drawings for the laser cutter and 3-D for the 3-D printer.

Since purchasing the Makerbot Replicator2, I have built a couple of other 3-D printers from kits as Christmas present (to myself!) projects (Printerbot Simple and Renkforce RF1000), and have bought a cheaper, semi-kit printer to evaluate for club use, the Hobbyking Print-Rite DIY printer (also advertised as the Colido DIY 3-D Printer). I illustrate and discuss these printers in Part III, the 3-D section of this book.

As you may have gathered, I find CAD drawing and the production of models via the laser cutter or 3-D printer an absorbing hobby in itself. I do now tend to look at kits in model shops and think I could make that.

True to Sods Law, three weeks before I was approached with a view to writing this book I had dismantled my 4mm railway to begin another, so many of the photographs in the book are of isolated items, rather than showing them in situ on a layout.

If you simply want to continue to model in traditional ways and enjoy doing so, then this book may not be for you. If, however, like me, you enjoy learning new skills and techniques and embracing new technologies, or just like to see how many bought items are made, then I hope some of my knowledge and personal experience of laser cutting and 3-D printing machines will be of interest.

Bob Gledhill, 2016

INTRODUCTION

This book shows you how laser cutting and 3-D printing machines can be used to enhance our railway modelling hobby. It sets out to explain how these machines work, with copious examples of what they can produce, and the pros and cons of ownership. If you are thinking of buying a machine, have just bought one, or are simply interested in how they work and what they can make, then this book will prove of interest.