Berger Paul - Woodworking Basics: How to setup a small workshop

Here you can read online Berger Paul - Woodworking Basics: How to setup a small workshop full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2020, genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Woodworking Basics: How to setup a small workshop

- Author:

- Genre:

- Year:2020

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

Woodworking Basics: How to setup a small workshop: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Woodworking Basics: How to setup a small workshop" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Berger Paul: author's other books

Who wrote Woodworking Basics: How to setup a small workshop? Find out the surname, the name of the author of the book and a list of all author's works by series.

Woodworking Basics: How to setup a small workshop — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Woodworking Basics: How to setup a small workshop" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

- Tape measure

- Steel ruler

- Try square

- Combination square

- Carpenter's square

- Straightedge

- Level

- Chalk line

- Sliding bevel

- Trammel points

- Marking gauge

- Cutting gauge

- Mortise gauge

- Awl

- Dovetail square

- Chisels (paring, firmer, butt, mortise)

- Sharpening stone

- Honing guide

- Gouges (wood carving set)

- Router and bits

- Utility knife

- Single edge razor blade

- Scissors

- Wire cutters

- Tin snips

- Handsaws (rip, crosscut, backsaw, coping, compass, flush-cutter)

- Miter box with integral saw

- Hacksaw

- Circular saw

- Saber saw

- Nails (finishing, common, box, ring-shank)

- Brads

- Screws (flat, round, and oval head)

- Sandpaper

- Pumice stone

- Steel wool

- Glues (woodworker's, white, contact cement, epoxy, instant)

- Wood putty

- Masking tape

- Pencils and markers

- Wood finishes and appropriate solvents

- Household oil o Penetrating oil

- Sponges

- Rags

- Push drill

- Hand drill

- Brace

- Gimlet or screw starter

- Electric drill (cordless and corded)

- Hand planes (block, jack, jointer)

- Scrapers

- Files (flat, half-round, round, triangular)

- Rasps (patternmaker's)

- Sanding blocks (flat and contoured)

- Orbital sander

- Wooden mallets (square and round heads)

- Rubber mallet

- Claw hammer

- Nail sets

- Utility bar

- Tack hammer

- Screwdrivers (offset, stubby, cabinetmaker's in flat-, Phillips- and square tip varieties)

- Nut drivers

- Pliers (standard slip joint type)

- Locking pliers

- Channel-joint pliers

- Wrenches (adjustable, open-end)

- Trigger clamps

- Quick-action bar clamps

- Bar clamps

- Pipe clamps

- Spring clamps

- Web clamps

- Hand screws

- Foam brushes

- Lint-free cloths

- HVLP sprayer

- Paint scraper

- Molding scraper

- Putty knife

Font size:

Interval:

Bookmark:

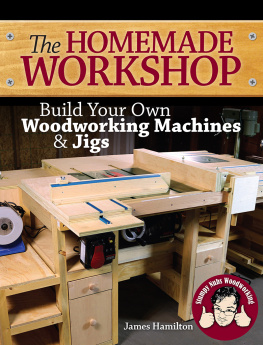

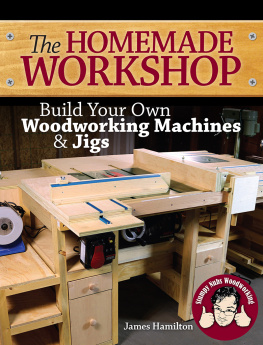

Similar books «Woodworking Basics: How to setup a small workshop»

Look at similar books to Woodworking Basics: How to setup a small workshop. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Woodworking Basics: How to setup a small workshop and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.