Thank you for purchasing this Popular Woodworking eBook.

Sign up for our newsletter and receive special offers, access to free content, and information on the latest new releases and must-have woodworking resources! Plus, receive a coupon code to use on your first purchase from ShopWoodworking.com for signing up.

or visit us online to sign up at

http://popularwoodworking.com/ebook-promo

Contents

The unique sliding top makes joinery tasks safe and easy.

Make precise adjustments from above, or use the lift itself as a fully functional mini table.

The lead screw positioner enables this fence to do more than any homemade version ever has.

Turn a hand-held power tool into a benchtop machine that can do things a band saw cant.

Keep the dust out of your lungs while sanding, and use the T-tracks for countless workholding applications.

Increase your vacuums efficiency and eliminate filter clogs.

Create box joints, splined miters, tenons and more with the micro-adjustable joinery attachments.

A crank-feed belt, swappable drums and top access for quick sanding make this sander unlike any other.

Despite having the throat capacity of giant industrial models, this three-wheel saw fits on a benchtop.

This unique homemade fence design has all the extras we wish the expensive commercial models included.

The precision and convenience of a high-end European saw come to your workshop!

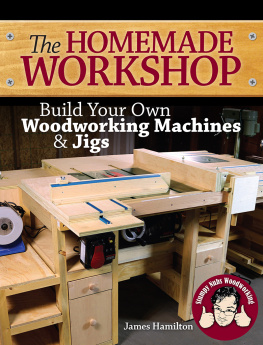

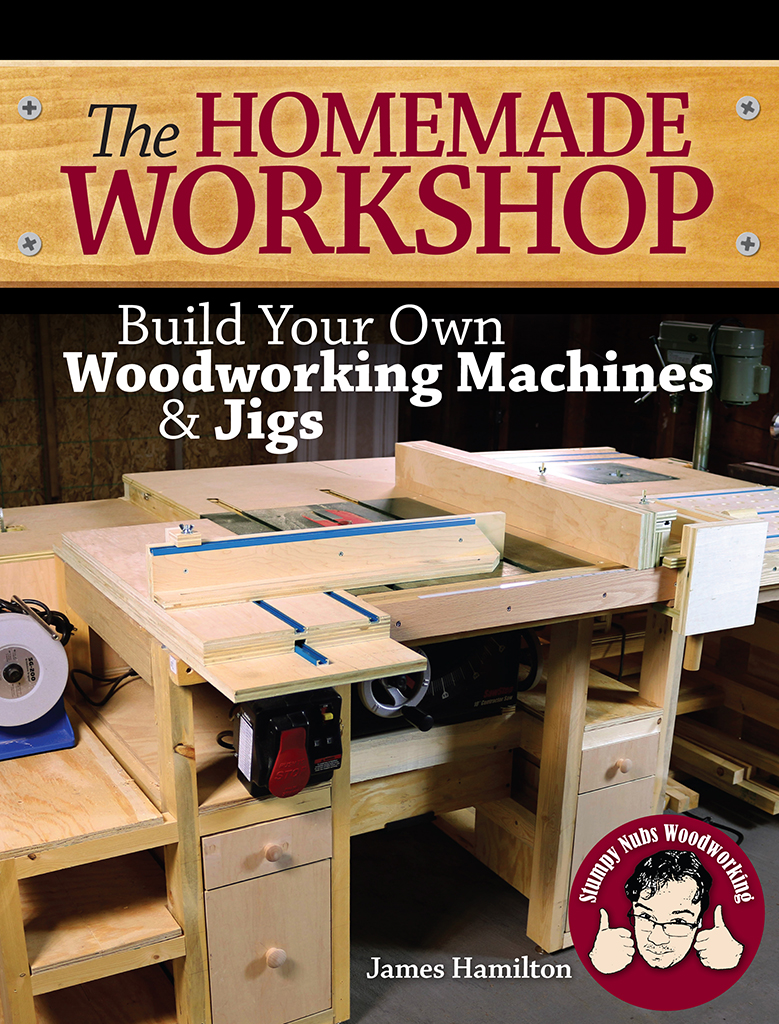

Build a complete workshop in a 4' x 8' footprint.

Introduction

When I put together my first workshop, I couldnt afford a band saw. Now, I could have scrimped and saved, maybe skipped a few trips to the buffet until I gathered the funds together for a good used model. But I come from a long line of tinkerers. My great grandfather was an iron worker. My grandfather was a well driller. When they had a problem, they built their own solution out of the materials they were familiar with (and a little bit of duct tape). So I wondered, was it really possible to build my own band saw?

It didnt take me long to find my answer. It turns out that homemade woodworking machines used to be quite popular. In the days before moderately priced imports, tools were very expensive. So innovative woodworkers began making their own. One of my favorites was found in an old issue of Popular Mechanics magazine. It was a detailed plan for a band saw built from steel pipe fittings. Later I learned that at least one company (Gilliom Manufacturing under the name Gil-Bilt) had for years manufactured bits of hardware that could be combined with wood to create all sorts of woodworking machines. I found that, not only was it possible to make my own tools, but that people had been doing it for decades!

That is until the 1980s. The decade of stonewashed jeans and hair bands also saw an influx of imports from the Asian markets. Suddenly a new band saw could be had for half the price as before. The homemade tool revolution dwindled as quickly as Don Johnsons career after Miami Vice. But enough with the 80s pop culture references; lets get to the heart of the matter. These days homemade woodworking tools are making a comeback. But it isnt all about saving a few bucks.

WHY BUILD YOUR OWN TOOLS?

More Features

I feel like the tool manufacturers have let us down. Theyve been pumping out the same old stuff for years with few new innovations. There are some exceptions, of course. But many of the most common machines havent changed in generations. Lets stick with the band saw as an example. Todays new models look very much like the old belt-driven machines in museums. Meanwhile a guy named Bell invented a box with a microphone that evolved from the candlestick telephone to party lines, touch-tone dials, cordless phones, cell phones and now Internet video connections and were still using the same band saw design!

Wheres the built-in sliding crosscut table, the integrated dust collection that actually collects dust, or the space-saving design that gives you more than 14" of throat depth without requiring a 10' machine with giant wheels? My homemade version has all of those features, and thats just a start.

You see, when you build it yourself, you get to decide what features are important to you. With a little thought (along with some help from this book and the content at stumpynubs.com ) you can make machines that are light years ahead of those available in stores.

Less Cost

Building your own woodworking machines is a great way to save money, if youre into that sort of thing. (Which I am.)

Because the band saw example has been working for us so well, lets consider it again. I am the proud owner of a 1hp, 14" band saw that is considered a fairly premium model. It cost me $1,000. You can buy less expensive saws, but not with the features that come in this price range. I also own a homemade saw of my own design. It has all of the features that my $1,000 saw has, plus a lot more. It cost me about $100 to build, including a used motor. But that doesnt tell the whole story. My homemade saw has 24" of capacity. A 24" band saw on the commercial market will cost you several thousand dollars more.

I also have a homemade horizontal router, a drum sander, a router joinery machine, a dovetail machine and all sorts of other machinery thats rarely ever found in a small shop, because the commercial versions are far beyond the financial means of the average woodworker. My shop is vastly better equipped than many professional shops for one simple reason: I made my own tools.

Greater Access

We finance the work we do, in part, through the sale of plans and building instructions for the machines I design ( stumpynubs.com/homemade-tools.html ).

Thousands of woodworkers have built these machines, which is something I take a great deal of pride in. But the best part of my job is reading email from woodworkers who live in areas where woodworking machinery is either difficult to find or prohibitively expensive to import. Many in Europe, Africa and Asia have found that building their own machines is the only way they could ever hope to own some of the tools that others find easy to acquire.

That band saw that cost $1,000 in the United States is two or three times that cost in some countries. Others simply cant find a commercial version for sale at all. While availability isnt an issue for everyone, for some it is a big reason to build their own tools.

Bragging Rights

My neighbor once came to my shop to show me a cutting board hed made. He was very proud of his work, as everybody is when they create something with their own hands. I complimented him and chatted about it until he mentioned that he still had to finish the sanding. Being a good neighbor, I offered to do it for him, flipping on my homemade drum sander. His jaw dropped as I fed it through, making a point to adjust every knob and crank as if it were H.G. Wells time machine. You may think me cruel to show him up like that, but you dont know my neighbor.