The Ultimate

Router Guide

Jigs, Joinery,

Projects & More from

Popular Woodworking

Edited by David Thiel

Contents

INTRODUCTION

I LOVE ROUTERS. In fact, as Im writing this I can hear the high-pitched whine of a 2 hp router bearing into the edge of a piece of wood begging to be formed. Okay, I love most things about routers. They are a little noisy, and they do make dust, but I see those as necessary by-products of an incredibly versatile workhorse that will always have a home in my shop.

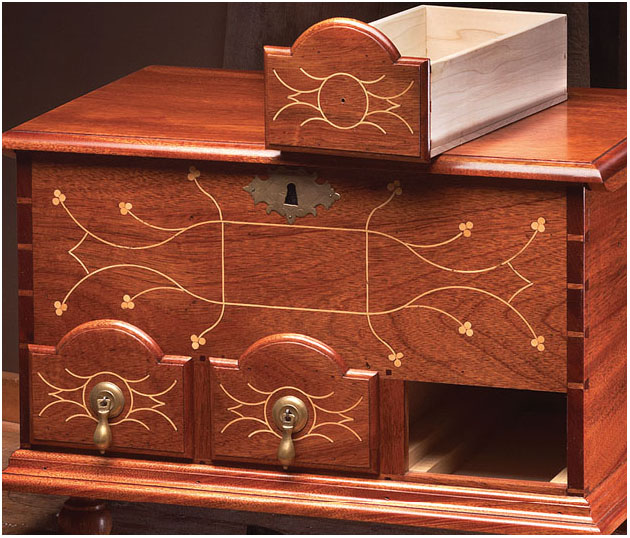

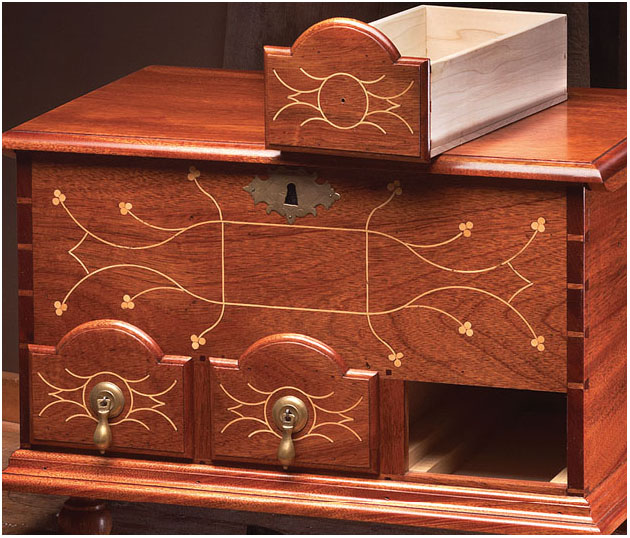

From edge treatments, to joinery, to inlay, to cleaning up rough cuts and in some cases using them as a jointer or planer, the router can do almost everything in the shop. They come in a wonderful array of styles and sizes, and I honestly feel that a shop with less than three routers is woefully handicapped.

This book is a collection of some of the best information on routers ever published in Popular Woodworking Magazine. Starting with a terrific primer on all things router by Nick Engler, youll learn how to choose the right router for each specific job, then learn all about bits, maintenance, applications and, well ... everything you need to know.

Then weve collected some great articles on joinery that is specifically created using a router, with pros, cons and variations that will teach and also make you think about other ways to put the router to work in your shop.

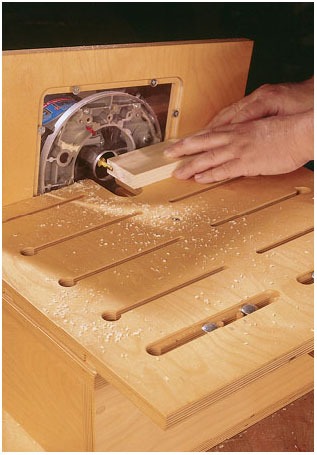

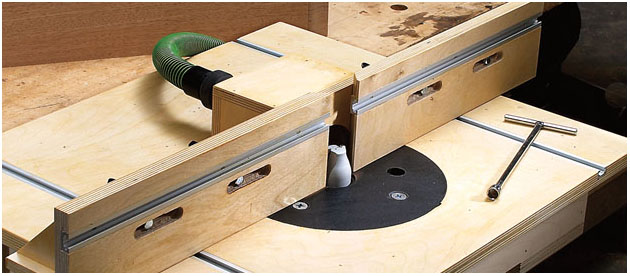

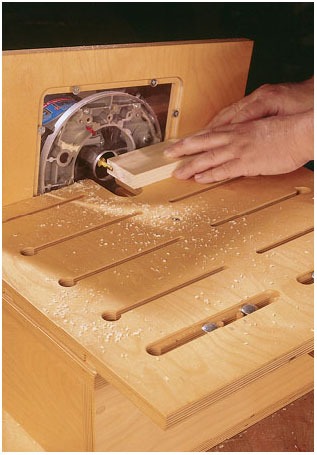

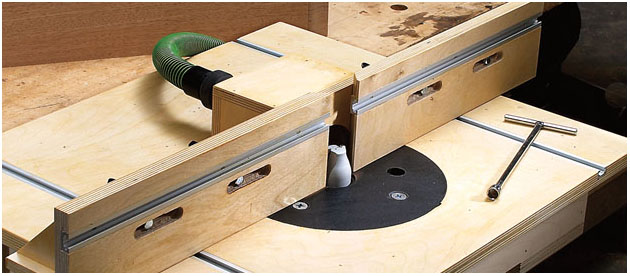

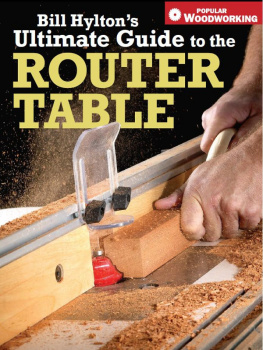

To follow that section we have router jigs to make using routers easier ... and expand the useful horizons of these wonderful machines. And lest we forget what may be the best of all router attachments, weve included a section on using routers in tables. Even more variation!

To round things out weve added a few woodworking projects that put the router to work in all applications.

Whether its a small trimmer that fits snuggly in the palm of one hand (offering terrific control) or a 3hp monster mounted in a router table creating cope-and-stick joinery for an entry door, routers are amazing tools!

If this is your first introduction to the router, I hope youll find it as amazing a tool as I do. And if youre already familiar with routers, I hope youll find ways to expand their use in your woodworking.

David Thiel

Editor

1 A ROUTER PRIMER

Fixed-base Router

by Nick Engler

The router is perhaps the most versatile tool in your shop. You can rout not only decorative shapes, but also many joints.

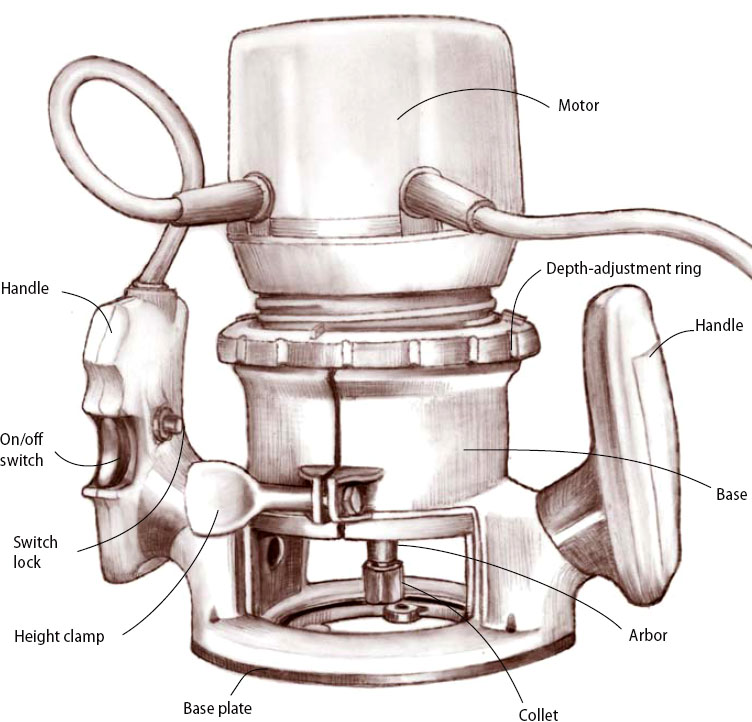

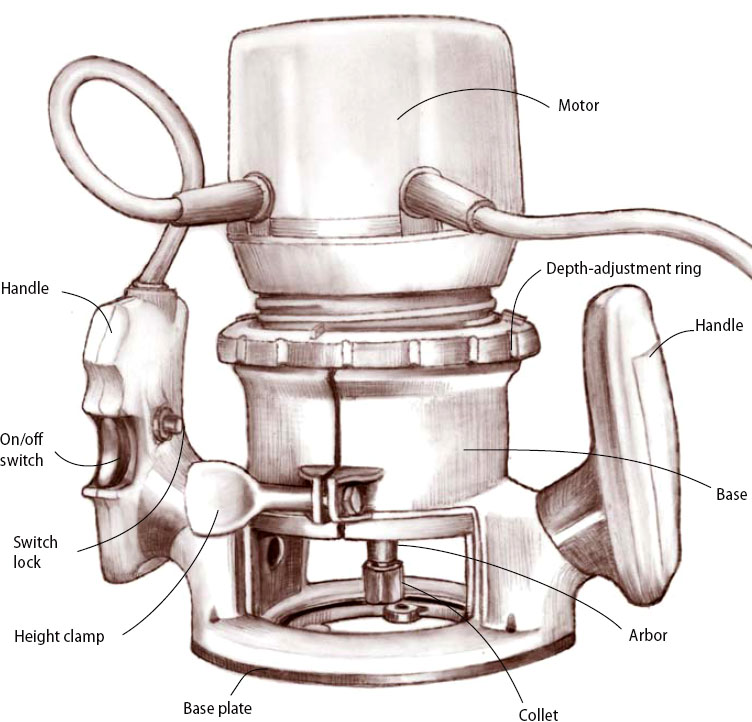

Reduced to its simplest form, the router is a motor and a shaft with means of holding interchangeable bits. Once you understand that, using the router becomes a much simpler task. But first, you should know what all those other parts are, and why theyre there.

Types of Routers

When you look for a portable router, you will find that they can generally be classified into four categories:

The Basic Router: Sometimes called a fixed-base router, this is just a motor mounted on a base. Most offer 12- to 112-horsepower motors, and their collets will accept router bits with 14" or 12" shanks. The bases are usually 6" in diameter. This is the router we will be discussing here.

The Laminate Trimmer: A scaled-down version of the basic router, this has a smaller motor and base. It has a 14" collet and is used for trimming laminates and veneers, and is especially handy when you are balancing the tool on thin or narrow workpieces. Its also useful for chores that require finesse, as opposed to strength. Some laminate trimmers come with interchangeable bases that let you work in tight areas or will allow you to rout at an angle, which no full-size router can.

The Rotary Tool: This lets you use very small bits and accessories for more delicate work. Its a carving or engraving tool (such as a Dremel) that can be mounted in a router base accessory. It usually has interchangeable collets for 116" or 18" shanks. The small size lets you rout inlays, cut mortises for small hardware, make delicate joints or do other jobs where a standard-size router would be too clumsy or difficult to balance.

The Plunge Router: This does all the things that the basic router can do, plus it makes plunge cuts. Its motor is mounted on two spring-loaded slides above the base, which let you position the motor above the work, push the bit into the wood and begin cutting. The plunge router excels at cutting joints, such as mortises.

PRO TIP

Back-routing (climb-cutting)

Occasionally you must back-rout a piece to reduce tear-out on figured wood. This means you cut with the bits rotation, instead of against it. Its much more difficult to control your work this way, so be sure to take shallow cuts and feed very slowly. Keep the router and the work steady, making sure you dont let the bit chatter.

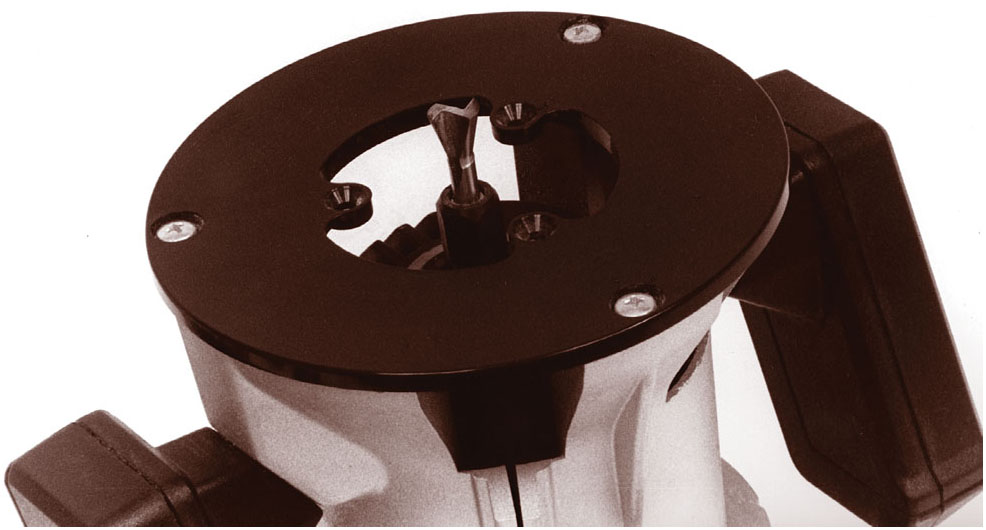

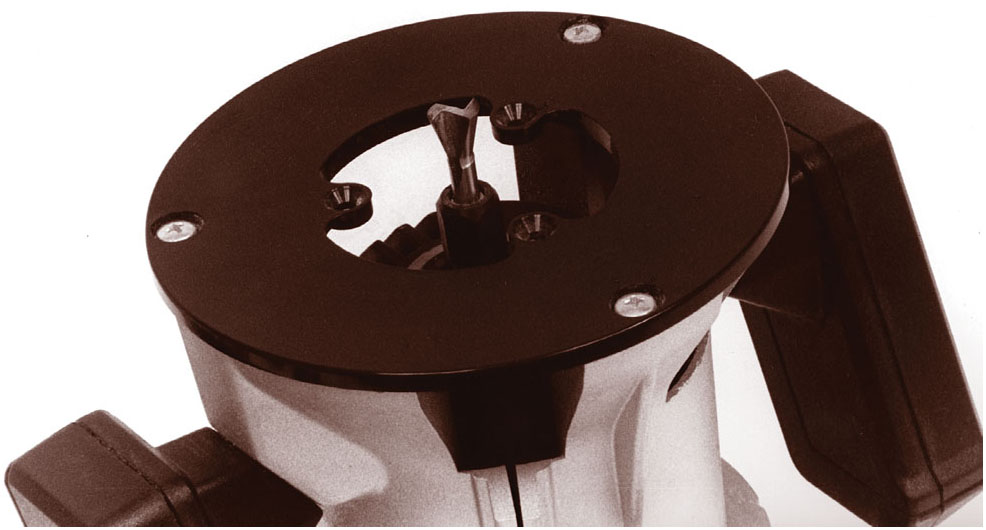

The bulk of the router is its motor. An arbor protrudes from the bottom of this, and the end of the arbor is fitted with a collet to hold a bit in place. These three pieces are mounted in a base, which incorporates a depth-adjustment ring to raise or lower the motor, and a height clamp to secure it in position these clamps differ for the plunge router, as youll see in the . A router also has handles so it can be guided, with a nearby on/off switch. This entire assembly rests on a removable plastic base plate or sole.

ILLUSTRATION BY MARY JANE FAVORITE; PHOTO COURTESY OF PATRICK WARNER, PATWARNER.COM

![Sagar Ganatra [Sagar Ganatra] - React Router Quick Start Guide: Routing in React Applications Made Easy](/uploads/posts/book/119450/thumbs/sagar-ganatra-sagar-ganatra-react-router-quick.jpg)