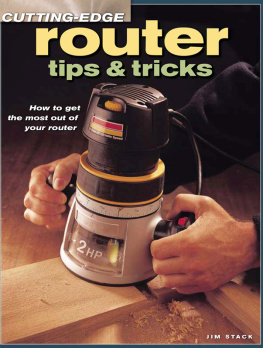

CUTTING-EDGE

router

tips & tricks

How to get the most out of your router

JIM STACK

Cutting-Edge Router Tips & Tricks. Copyright 2005 by Jim Stack. Printed and bound in China. All rights reserved. No part of this book may be reproduced in any form or by any electronic or mechanical means, including information storage and retrieval systems, without permission in writing from the publisher, except by a reviewer, who may quote brief passages in a review. Published by Popular Woodworking Books, an imprint of F+W Publications, Inc., 4700 East Galbraith Road, Cincinnati, Ohio, 45236. First edition.

Visit our Web site at www.popularwoodworking.com for information on more resources for woodworkers.

Other fine Popular Woodworking Books are available from your local bookstore or direct from the publisher.

09 08 07 06 05 5 4 3 2 1

Library of Congress Cataloging-in-Publication Data

Stack, Jim, 1951

Cutting-edge router tips & tricks : how to get the most out of your router / Jim Stack p. cm.

Includes index.

ISBN 1-55870-713-1 (hardcover: alk. paper)

eISBN-13: 978-1-4403-1625-8

ISBN 1-55870-698-4 (paperback: alk. paper)

1. Routers (Tools) 2. Woodwork. 3. Jig and fixtures. I. Title: Router tips & tricks. II. Title: Cutting-edge router tips and tricks. III. Title.

TT203.5.S73 2005

684'.08 dc22 2004054690

Editor: Amy Hattersley

Designer: Brian Roeth

Layout artist: Joni DeLuca

Production coordinator: Robin Richie

Photographer: Al Parrish (pages 2, 9, 92, 102, 116)

Book photographer: Jim Stack

Technical illustrator: Jim Stack

METRIC CONVERSION CHART

to convert | to | multiply by |

Inches | Centimeters | 2.54 |

Centimeters | Inches | 0.4 |

Feet | Centimeters | 30.5 |

Centimeters | Feet | 0.03 |

Yards | Meters | 0.9 |

Meters | Yards | 1.1 |

Sq. Inches | Sq. Centimeters | 6.45 |

Sq. Centimeters | Sq. Inches | 0.16 |

Sq. Feet | Sq. Meters | 0.09 |

Sq. Meters | Sq. Feet | 10.8 |

Sq. Yards | Sq. Meters | 0.8 |

Sq. Meters | Sq. Yards | 1.2 |

Pounds | Kilograms | 0.45 |

Kilograms | Pounds | 2.2 |

Ounces | Grams | 28.4 |

Grams | Ounces | 0.035 |

READ THIS IMPORTANT SAFETY NOTICE

To prevent accidents, keep safety in mind while you work. Use the safety guards installed on power equipment; they are for your protection. When working on power equipment, keep fingers away from saw blades, wear safety goggles to prevent injuries from flying wood chips and sawdust, wear head-phones to protect your hearing and consider installing a dust vacuum to reduce the amount of airborne sawdust in your woodshop. Don't wear loose clothing, such as neckties or shirts with loose sleeves, or jewelry, such as rings, necklaces or bracelets, when working on power equipment. Tie back long hair to prevent it from getting caught in your equipment. People who are sensitive to certain chemicals should check the chemical content of any product before using it. The authors and editors who compiled this book have tried to make the contents as accurate and correct as possible. Plans, illustrations, photographs and text have been carefully checked. All instructions, plans and projects should be carefully read, studied and understood before beginning construction. Due to the variability of local conditions, construction materials, skill levels, etc., neither the author nor Popular Woodworking Books assumes any responsibility for any accidents, injuries, damages or other losses incurred as a result of the material presented in this book. Prices listed for supplies and equipment were current at the time of publication and are subject to change. Glass shelving should have all edges polished and must be tempered. Untempered glass shelves may shatter and can cause serious bodily injury. Tempered shelves are very strong and if they break will just crumble, minimizing personal injury.

For all the woodworkers who own or will soon own a router

For all the woodworkers who own or will soon own a router

About the Author

Jim Stack is the Acquisitions Editor for Popular Woodworking Books. Before that he worked in commercial cabinet- and furniture-making shops for 20 years.

Acknowledgements

Thanks to my Popular Woodworking Books team, namely, associate editor Amy Hattersley, designer Brian Roeth and production coordinator Robin Richie for their help and patience in creating yet another great-looking book!

Thanks to Al Parrish for his photos of the finished projects. He's an artist with light.

I would like to acknowledge the countless woodworkers that have taught me (knowingly and unknowingly) about design, techniques and how to use tools. I learn something new every day by watching you do what you do best.

When I saw the jig that John Hutchinson made for routing the lids on his shell boxes, I knew it was a perfect addition to this book. Thanks for your infectious creativity John!

introduction

R outers are noisy, make lots of dust and can be dangerous. Did I say they're loud, dirty and can jump out of your hands? So why do woodworkers have a love affair with this handheld power tool?

The router has been around for 70 or 80 years now, and hasn't changed in looks much at all. A router is a motor mounted inside a housing. The motor's shaft has a collet on one end to which steel cutters can be mounted. The first routers were large (you definitely needed two hands to operate them), had steel housings (which made them heavy) and motors that could give you a good jolt if they wanted to. Router motors are now double-insulated and the housings are made of high-impact plastic, both of which mean you won't get shocked if something shorts out unexpectedly. Also, they are smaller and lighter in weight, so sometimes you only need one hand to operate the router.

By definition, to rout means to cut or plow a groove or furrow. A router is the tool that does just that. However, it was discovered early on that the router could be fitted with cutters and guided along the edges of boards to cut moulding profiles. Not only that, it could cut grooves and tenons and make joints!

Hundreds (dare I say thousands) of cutters and bits are available for use in the router. This tool has added a whole arsenal for woodworkers to use in building cabinets and furniture. Those of us who have worked in commercial cabinet-and furniture-making shops have used the router for just about everything, from cutting grooves and profiles to edge-joining boards and cutting panels to size. Home woodworkers are now able to perform all these operations.

![Sagar Ganatra [Sagar Ganatra] - React Router Quick Start Guide: Routing in React Applications Made Easy](/uploads/posts/book/119450/thumbs/sagar-ganatra-sagar-ganatra-react-router-quick.jpg)

For all the woodworkers who own or will soon own a router

For all the woodworkers who own or will soon own a router