Getting Started with 3D Printing

by Liza Wallach Kloski and Nick Kloski

Copyright 2016 HoneyPoint3D. All rights reserved.

Printed in Canada.

Published by Maker Media, Inc. , 1160 Battery Street East, Suite 125, San Francisco, CA 94111.

Maker Media books may be purchased for educational, business, or sales promotional use. Online editions are also available for most titles (http://safaribooksonline.com). For more information, contact OReilly Medias institutional sales department: 800-998-9938 or corporate@oreilly.com .

- Editor: Roger Stewart

- Technical Reviewer: Matt Stultz

- Production Editor: Colleen Cole

- Copyeditor: Kim Cofer

- Proofreader: Charles Roumeliotis

- Indexer: WordCo Indexing Services

- Interior Designer: David Futato

- Cover Designer: Karen Montgomery

- Cover Illustration: HoneyPoint3D

- Illustrator: Rebecca Demarest

Revision History for the First Edition

- 2016-04-27: First Release

See http://oreilly.com/catalog/errata.csp?isbn=9781680450200 for release details.

Make:, Maker Shed, and Maker Faire are registered trademarks of Maker Media, Inc. The Maker Media logo is a trademark of Maker Media, Inc. Getting Started with 3D Printing and related trade dress are trademarks of Maker Media, Inc.

Many of the designations used by manufacturers and sellers to distinguish their products are claimed as trademarks. Where those designations appear in this book, and Maker Media, Inc. was aware of a trademark claim, the designations have been printed in caps or initial caps.

While every precaution has been taken in the preparation of this book, the publisher and authors assume no responsibility for errors or omissions, or for damages resulting from the use of the information contained herein.

978-1-680-45020-0

[TI]

Foreword

If youre reading this book, that means that youre about to embark on a potentially life-changing journey.

Theres a good chance that a 3D printer will wind up in your home, if it hasnt already, and youre going to need to know how to use it.

Getting Started with 3D Printing can be your guide through the trials and tribulations of the 3D printing learning curve.

When you begin, you may not know a thing about this game-changing technology, but as you follow along with this book, you will be initiated into an elite society of alchemists who are capable of transforming the very matter of the physical world around you. Like me, you will become a maker.

Makers date back tens of thousands of years. While Neanderthals were roaming around the plains of the Serengeti, dragging their knuckles through the dirt, we makers were learning to transform sticks, stones, and animal bones into tools with which to hunt and survive. By the time some made rocks with handles, we makers had already moved on to bronze, smelting spearheads, and proto-writing our names into mountaintops.

The times have changed, but our powers have not.

The newest generation of makers wield the tools of digital fabrication to transmute thought into reality. The CNC machine carves metal, the laser cutter etches wood, and the PCB writer harnesses the power of electricity to drive even the most complex of robotics. But there may be no tool of alchemy more powerful than the 3D printer.

I can tell you from personal experience that learning how to 3D print may not always be fun, but it will always be rewarding. I remember watching my first test cube begin printing, and it was nothing short of miraculous. I had found the digital model on Thingiverse and, all of a sudden, it was materializing before my eyes.

Life, when you love 3D printing, can be a tumultuous one of clogged print heads, broken belt drives, and unruly 3D CAD models. There is hope, but you have to start somewhere. And theres no better place to start than with this book, written by two educational alchemistsLiza Wallach Kloski and Nick Kloski of HoneyPoint3D.

They have already empowered more than 6,000 apprentices, having successfully launched their own wildly popular educational program devoted to teaching the ins and outs of 3D printing. Liza and Nick will be able to accompany you on your journey as two helpful guides who will be there for you when your wires are crossed, your extruders are clogged, and your bed isnt level.

Soon, you will understand how to turn the mental into the physical, the digital into the material. Youll be able to clone everyday items, teleport them across thousands of miles, or reconfigure them to suit your own needs. Youll befriend other mystics, like yourself, who can help you to hone your powers. You might even join a local chapter of the elders, a makerspace, where secret rites and rituals will see you unite your powers with the collective to unleash even mightier projects on the world at large. And as the technology grows more powerful as a result, youll be able to fabricate almost anything, practically out of thin air, moving from full color sculptures to complete electronic devices!

That is what you can expect when you end your journey. Once you complete this guide, you, my friend, will become one of the initiated. You will be a maker.

Michael Molitch-Hou

Editor-in-Chief

3D Printing Industry (3DPI)

The leading news site dedicated to 3D printing

An Introduction to 3D Printing

Feel fortunate! You are living at a time when technology is increasingly helping people become masters of their environments. A 3D printer puts the power of a manufacturing plant on your desk and opens worlds of opportunities that you (and the rest of humanity) have never experienced before.

.

Using an open source design (which grants a free license to a products blueprints), dedicated hobbyists were able to affordably access what was otherwise a very expensive technology. This marked a cornerstone in the ability of ordinary customers to access desktop 3D printing.

Fast-forward to 2016. The 3D printing industry (industrial and consumer combined) is now estimated at around $7 billion and is expected to exceed $17.2 billion by 2020. No one has a crystal ball to know the future, but it seems certain that 3D printing will change the way we as a society design and manufacture physical items.

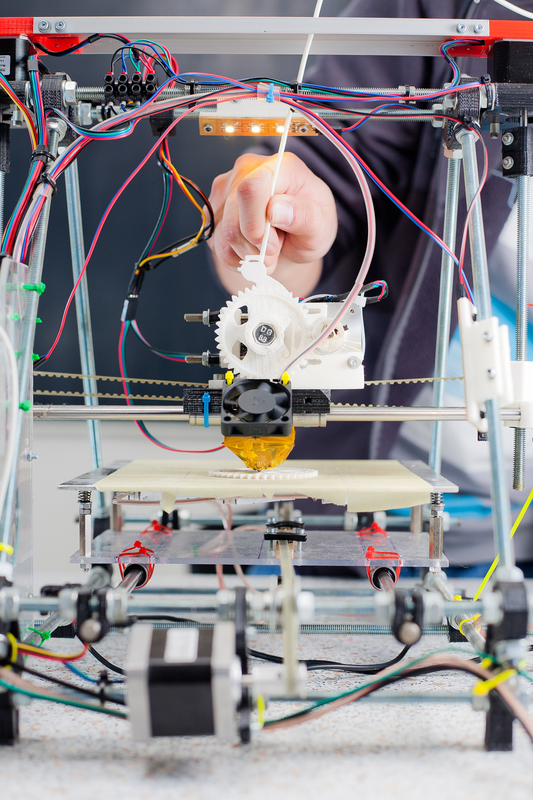

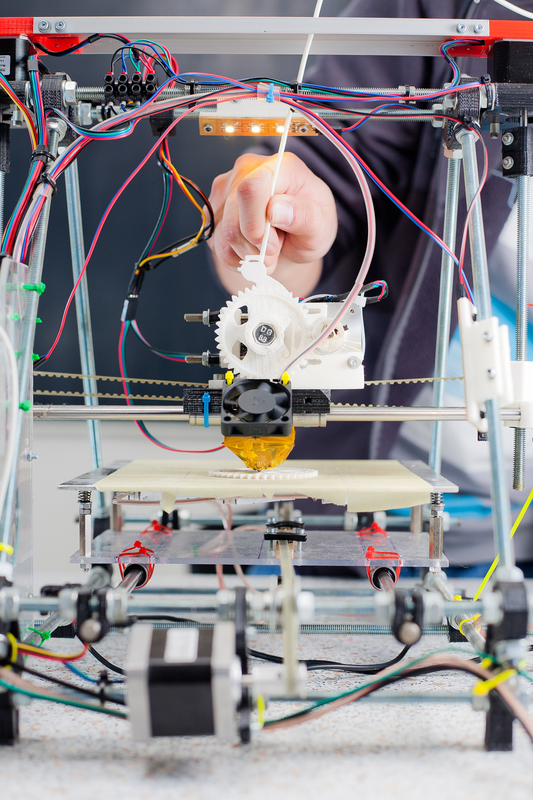

Figure P-1. An early example of an assembled open source 3D printer kit

How 3D Printing Works

The most common type of consumer 3D printing, also known as additive manufacturing, is called FDM (fused deposition modeling) or sometimes FFF (fused filament fabrication). FDM printers create objects by adding material in successive layers, building up an object layer by layer over time. A thin strand of filament feeds into a part of the machine called an extruder, which melts the plastic at a high temperaturetypically around 200C. There are many other methods of 3D printing that this book will cover in later chapters, and they all work in the same additive way of creating an object by adding material layer by layer.

The most recognizable tool you can compare this process to is a hot glue gun. You probably have one at home and have used it for craft or school projects. When you squeeze the handle, the glue is pressed against a heating element and soft, spaghetti-like strands extrude from the nozzle. Imagine swirling those strands around and around on top of each other, forming circles that build up into a tube. As the glue cools, it hardens.

Following the glue gun analogy, in a 3D printer the thin strand of melted plastic is laid down, layer by layer, on a flat surface where it cools and hardens into an object. The image in provides a closer look at how this technology works.