To my grandfather, Lewis N. Higbee, and to all innovative spirits who love making things

Acknowledgments: Thank you to Maxim Lobovsky, Nadia Cheng, Hasti Afsarifard, Carlos Olguin, Amos Dudley, the HP 3D printing team, and Autodesk 3D printing, specifically Guillermo Melantoni and Sarah ORourke, for sharing and showing me their 3D printing expertise.

Thank you to Natalie and Judi Kledzik, Mona Sabet, and members of my childrens book critique group for all your reviews. A special thank-you to Susan Casey, Lisa Pampuch, and Marianne Wallace for encouraging me throughout the writing process.

Thank you to San Mateo Public Libraries for their resources and helpful staff, the UnaMesa Association for providing a serene place to write, and our babysitter, Kristi Fredrick, for being there whenever we needed her.

A special thank-you to my husband and son for giving me space and time to write and lots of ideas on how to tell the 3D printing story.

Text copyright 2018 by Lerner Publishing Group, Inc.

All rights reserved. International copyright secured. No part of this book may be reproduced, stored in a retrieval system, or transmitted in any form or by any meanselectronic, mechanical, photocopying, recording, or otherwisewithout the prior written permission of Lerner Publishing Group, Inc., except for the inclusion of brief quotations in an acknowledged review.

Twenty-First Century Books

A division of Lerner Publishing Group, Inc.

241 First Avenue North

Minneapolis, MN 55401 USA

For reading levels and more information, look up this title at www.lernerbooks.com.

Main body text set in Adobe Garamond Pro 11/15.

Typeface provided by Adobe Systems.

Library of Congress Cataloging-in-Publication Data

Names: Koch, Melissa, author.

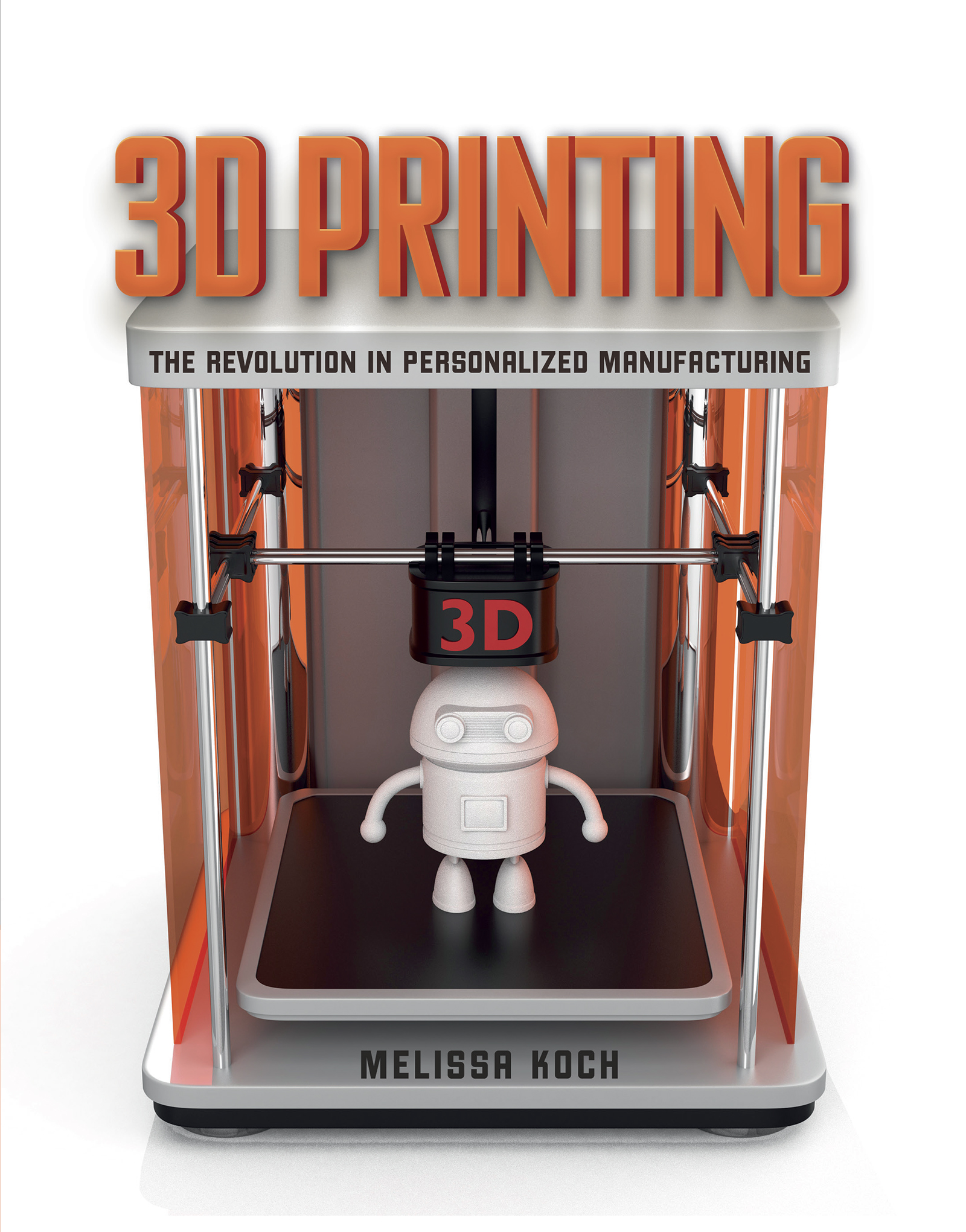

Title: 3D Printing : the revolution in personalized manufacturing / by Melissa Koch.

Description: Minneapolis : Twenty-First Century Books, [2017] | Includes bibliographical references and index.

Identifiers: LCCN 2016033030 (print) | LCCN 2016033530 (ebook) | ISBN 9781512415704 (lb : alk. paper) | ISBN 9781512448603 (eb pdf)

Subjects: LCSH: Three-dimensional printingJuvenile literature.

Classification: LCC TS171.95 .K63 2017 (print) | LCC TS171.95 (ebook) | DDC 621.9/88dc23

LC record available at https://lccn.loc.gov/2016033030

Manufactured in the United States of America

1-39927-21393-3/21/2017

9781512467741 mobi

9781512467758 ePub

9781512467765 ePub

Contents

Introduction:

Wasps Do It

Chapter 1

Inventing 3D Printing

Chapter 2

How It Works

Chapter 3

3D Printing and Traditional Manufacturing

Chapter 4

3D Printing Our Health

Chapter 5

3D Printing Our World

Chapter 6

3D Printing Our Future

Chapter 7

Disrupting and Democratizing Manufacturing

Introduction

Wasps Do It

The rhythmic buzzing and continuous oozing of a 3D (three-dimensional) printer can draw a crowd. Hypnotized, everyone watches as the printer deposits small bits of material, layer upon layer on a platform until slowly a new object emerges. Ready to use.

3D printing may sound like science fiction. Theres a reason for that: 3D printing has been a star of science fiction in television and film. For example, the technology appeared in scenes in Star Trek , the popular 1960s TV series. Later, in the 1980s TV show Star Trek: The Next Generation , the 3D printer was named the Replicator. In this series, crew members on the Starship Enterprise could order up and print anything they wanted. Viewers wished they had their own Replicators to make pizza and banana splits. In the twenty-first century, MakerBot even named its popular 3D printer Replicator.

We humans began actually experimenting with 3D printing in the 1980s. This style of printing is also known as additive manufacturing because it adds materials layer upon layer to create a 3D object. But humans were not the first to develop 3D printing. Wasps were additive manufacturers long before us. The method paper wasps use to build their homes reveals the basics of 3D printing.

Human WASP Engineers

Wasps build the hexagonal cells of their colonies in layers. Inspired by this natural technology, human entrepreneurs have modeled 3D printing techniques to build houses and other structures layer by layer.

Wasps live in nests in communities called colonies. A queen wasp starts a colony by building a nest. She uses her mandibles (appendages near the mouth) to scrape wood pulp from trees, fence posts, and even cardboard into her mouth. Mixed with her saliva, these materials become a watery pulp. The queen finds a good location for building the nest. She spits out the pulp, layer by layer, to create hexagonal (six-sided) cells in which her young will develop. As the number of wasps in the colony grows, the new generations of worker wasps construct new cells the same way the queen did.

In 2012 an engineering team in Italy known as the Worlds Advanced Saving Project (WASP) closely watched wasps, specifically the mud dauber wasp, at work. The human WASP team decided to build 3D printers to mimic the wasps technique. The WASP engineers collect large chunks of clay, sand, plant, and other soil materials and put them into a custom-made, 20-foot-tall (6-meter) 3D printer to print a house, layer by layer. The house cost almost nothing to print because the nontraditional building materials are gathered at the site. The team creates these homes at locations where typical building materials (bricks, stones, and wood) are inaccessible or too costly to use for homes and other buildings.

3D printing can change not only where people live but how they live. For example, high school students in Van Buren, Ohio, used a 3D printer to create a prosthetic hand for a toddler in their town. The students gathered thirty dollars worth of plastic, melted it into liquid form, and put it into the schools 3D printer. They used 3D computer-aided design (CAD) software to design the hand. Thomas Wolford, a senior at Van Buren High School, described the printing process. The nozzle goes around it all in crazy funky patterns and prints it out layer by layer, he said. Another senior, Aaron Scasny, added, We ran fishing wire down through the bottom [of the hand] and this elastic threaded cord through the top, so when you bend it, it acts like tendons in your hand. Because young children outgrow their prosthetics, outfitting them with artificial limbs was expensive in the past. But 3D printing has made it possible for more children and adults to have the prosthetics they need because they can afford it.

Teens in Ohio 3D printed a prosthetic hand for Addy Johnson at their school. The technologies involved in 3D printing are available to all and are often used to improve everyday life for individuals.

Bioprinters

In the medical field, 3D printing is a modern superpower. With bioprinters, bioprinting researchers from all over the world have successfully re-created human ears, noses, skull bones, tracheas, bladders, and other body parts. The ink-jet printing of viable cells is one example of what a 3D printer can do. It deposits drops of human cellular material and proteins onto a platform in the same way an ink-jet printer drops ink onto a piece of paper. Traditional printers place one layer of ink onto one sheet of paper at a time. By contrast, a 3D ink-jet printer adjusts its platform up and down adding cellular material, layer by layer, until a 3D organ emerges.