Contents

The MIT Press Essential Knowledge Series

A complete list of the titles in this series appears at the back of this book.

2018 The Massachusetts Institute of Technology

All rights reserved. No part of this book may be reproduced in any form by any electronic or mechanical means (including photocopying, recording, or information storage and retrieval) without permission in writing from the publisher.

This book was set in Chaparral Pro by Toppan Best-set Premedia Limited. Printed and bound in the United States of America.

Library of Congress Cataloging-in-Publication Data

Names: Jordan, John M., author.

Title: 3D printing / John Jordan.

Description: Cambridge, MA : The MIT Press, [2019] | Series: The mit press

essential knowledge series | Includes bibliographical references and index.

Identifiers: LCCN 2018032130 | ISBN 9780262536684 (pbk. : alk. paper)

Subjects: LCSH: Three-dimensional printing.

Classification: LCC TS171.95 .J67 2019 | DDC 621.9/88dc23 LC record available at https://lccn.loc.gov/2018032130

10 9 8 7 6 5 4 3 2 1

Series Foreword

The MIT Press Essential Knowledge series offers accessible, concise, beautifully produced pocket-size books on topics of current interest. Written by leading thinkers, the books in this series deliver expert overviews of subjects that range from the cultural and the historical to the scientific and the technical.

In todays era of instant information gratification, we have ready access to opinions, rationalizations, and superficial descriptions. Much harder to come by is the foundational knowledge that informs a principled understanding of the world. Essential Knowledge books fill that need. Synthesizing specialized subject matter for nonspecialists and engaging critical topics through fundamentals, each of these compact volumes offers readers a point of access to complex ideas.

Bruce Tidor

Professor of Biological Engineering and Computer Science

Massachusetts Institute of Technology

Acknowledgments

The research librarians at the Penn State business library were invaluable in helping me find rare and important sources as well as to validate student usage of the MakerBots.

Bill Yackabonis at Autodesk, David Saint John at Linamar, and the team at the Penn State CIMP lab (especially the intellectually generous Tim Simpson) made me aware of emerging developments.

Working with the MIT Press on my second book with them was a pleasure. The editorial team of Marie Lufkin Lee, Stephanie Cohen, and Michael Sims guided me though the milestones, and the Press found excellent anonymous readers to help me push the project into some important areas I had overlooked in the initial proposal.

Special thanks go to CIMP-3D, Frustum, GE, and Unfold for allowing me to use their artwork in the book.

I appreciate the help of all of these contributors but all errors and infelicities in the final product are on my shoulders, not theirs.

1

Introduction

What Is Additive Manufacturing?

In the human history of making things, there have been several major steps. In oversimplified terms, there are three ways to fabricate: subtraction (hammering a flint arrowhead or whittling a stick), molding (pouring gold into a sand mold or concrete into forms), and addition (building a log cabin or a pyramid). In the nineteenth and twentieth centuries, advances in machineryincluding hydraulicsincreased the power for moving dirt, metal, or concrete, while new steel alloys for cutting tools and other innovations enhanced the precision of subtraction. In the realm of metalworking, however, the precision of subtraction far exceeded the precision of addition: even as recently as the 1990s, computer numerical control (CNC) machine tools as well as laser and waterjet cutters could remove material far more impressively and precisely than anything could add it.

Beginning in the 1980s, however, computers were harnessed to the task of adding minute amounts of material with heretofore impossible precision. Initially the machines were used to make plastic mock-ups of new computer-aided design (CAD) files and were known as rapid prototyping tools. By the early 1990s, the same approach was adapted to metal. In the twenty-plus years since, the advantages of additive manufacturing, as it has come to be called, continue to accumulate and move beyond prototyping into production.

Meanwhile, in classrooms and home workshops in many countries, low-cost machines for medium-precision forming of plastic have sold in large numbers. An ethos similar to the homebrew computer clubs of the 1980s motivates a maker culture of people who are familiar with computing, eager to create things, and share tips and designs through both physical and virtual networks. In many cases, computer files used to create small plastic items (whether a knob or a cartoon figure) are shared in line with the principles of open-source software. Additive manufacturing feels too heavy-duty and industrial for this branch of the technology, so we will refer to it as 3D printing. Overall, many in the industry use both terms interchangeably, and we will follow that convention when talking about commercial applications.

What Is 3D Printing?

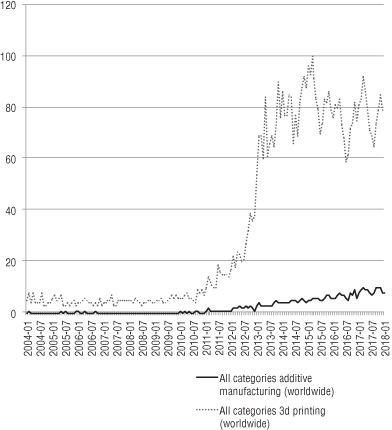

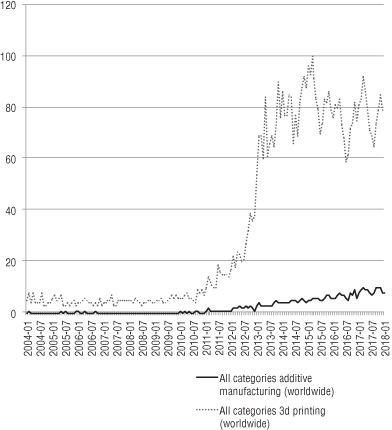

A word about usage: 3D printing is an accessible term, and can make the process sound simpler than it actually is. As one observer notes, rapid prototype that for me is much less intuitive or direct even though it would be more accurate for the first fifteen years of the technologys existence. In figure 1.1, we see from Google Trends data that the term 3D printing is far more commonly used than additive manufacturing, at least in web searches since 2004.

Why is the technology so important now? There are many reasons. First, ecological concerns, combined with economic logic, favor techniques of manufacturing that do not use expensive, time-consuming processes to mill away large quantities of metal, titanium alloy in the case of aerospace components. (The colloquial term here is the buy to fly ratio, referring to how much of the original metal ends up in the finished part.) Second, building up a work in process (to be subsequently worked via some other technology) allows for new geometries compared to cutting or molding. Examples include honeycomb structures that are extremely strong relative to their weight, or internal cooling channels in an industrial stamping tool. Third, the prospect of printing in mixed materials promises lower cost, higher strength, and cleaner design: imagine a football helmet with a radio antenna integral to the polycarbonate plastic body rather than being fabricated by an entirely separate supply chain and then glued on after molding. Fourth, many industries ranging from aerospace to construction equipment are intent on building an end-to-end digital thread to maintain the integrity of a design from specification to end use, and the computer-assisted fabrication of such parts maintains extreme fidelity between computer design and final product, reducing variability.

Figure 1.1 Interest in additive manufacturing, as measured by Google searches, has been growing steadily since about 2012, whereas 3D printing exhibits a more unstable pattern of pubic attention. (Data source: Google Trends)

On the 3D-printing front, the urge not only to create but to personalize some aspects of ones material environment is well served by this technology. As some key patents expired in the United States (particularly in regard to fused deposition modeling), home-market printer prices dropped by a factor of ten, to less than $1,000, after 2009. As we will see in chapter 4, a broadly based maker movement both was empowered by and created demand for 3D printers. Finally, the ability to personalize plastic output has merged with the use of smartphones for self-portraiture in 3D-printed figurines of real people: wedding cakes, to take just one example, can feature recognizable likenesses of the featured couple.

Next page