Contents

Projects

INTRODUCTION

In its current form, parachute cord is a product of the Second World War. Historically, silk was used in various lifesaving military applications due to its strength-to-weight ratio. Notable uses were webbed straps, parachute cloth, and shroud lines. After the attack on Pearl Harbor in 1941, however, trade with Japan ended, causing a shortage of silk and the need to find a replacement.

Nylon had been invented about six years earlier by Wallace Carothers at DuPont. The strong, lightweight, and consistent synthetic material actually proved superior to silk when utilized properly. The invention of nylon coupled with the military need for a silk replacement resulted in parachute cord (or paracord).

The military specifications for minimum standards of paracord are outlined by MIL-C-5040H in six types. The most common is Type III (type 3) or 550 parachute cord. The 550" is in reference to the minimum tensile strength specified by the US government. Initially, paracord was only available in olive drab and natural, an off-white color. Until recently it was a surplus item.

Due to its very high tensile strength, soldiers and sailors found many uses for paracord other than shroud lines, and it became a staple utility item for all branches of the military. It is believed that soldiers stationed in the Middle East are the catalyst of the recent popularity of this great cord. As a sort of modern trench art, paracord is tied into various useful items and accessories. The most common items are bracelets, given as gifts or sent home to loved ones.

Civilians wear these gift bracelets to show support for their friends and family in the military. They soon began to be marketed and worn as survival bracelets and advertised as a way to keep a necessary survival item at hand. These bracelets (as you will learn) are not only handy but also easy and fun to make.

The popularity of these bracelets encouraged manufacturers to develop and market commercial versions of paracord in many bright colors, color combinations, and sizes for the civilian market.

GETTING STARTED

Working with paracord is easy and fun. You only need a handful of items and several lengths of cord to get started making tons of handy projects. This section introduces you to the tools you will need to make the projects in this book. You will also find some great tips and tricks to make working with paracord as simple as possible.

The Anatomy of Parachute Cord

Paracord consists of an outer jacket of nylon strands braided over inner strands of twisted nylon (called filler). The number of strands used for the jacket and the filler varies by the size of the cord. In 550 cord (the most common type), there are thirty-two strands in the jacket and seven or eight strands of filler.

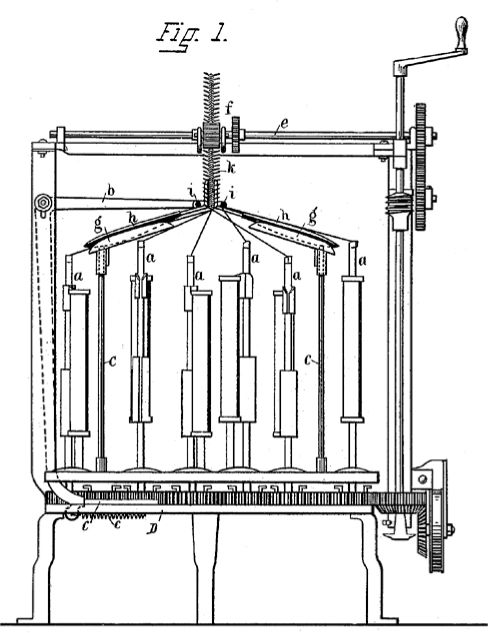

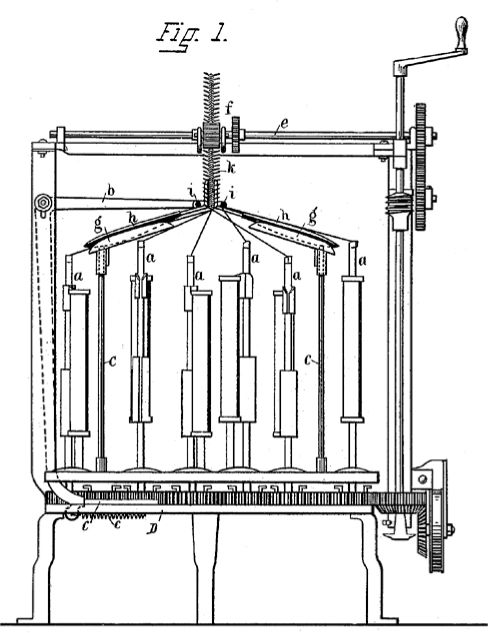

Paracord is manufactured using technology that dates to the late nineteenth century. The nylon yarn is wound onto bobbins and then braided on a machine called a Maypole Braider. The largest builder of these braiding machines was the New England Butt Company of Providence, Rhode Island. Though they are no longer in business, the machines they built continue to braid cord around the clock.

Even though nylon is a synthetic fiber, it is still subject to variations in size and color with each batch. This means that cord braided on the same machines from different lots of yarn may vary in color, size, feel, and shine.

Figure 1. These illustrations are from an 1888 patent for improvements to braiding machines that were commonly used during that time.

Figure 2. To braid the cord, bobbins wound with yarn are placed on carriers. A leather belt attached to a drive shaft moves the carriers, braiding the yarn around the filler strands.

Figures 3 and 4. The braided cord comes out of the top of the machine and around a takeoff reel, where it is collected in a basket or wound onto a spool.

Tools

Good sharp scissors, a butane lighter, and a yardstick or tape measure are all that you really need to start working with paracord. While these basic items will get you started, youll find that the additional items listed below can often make projects a little bit easier and therefore more enjoyable to make.

QUALITY SCISSORS

QUALITY SCISSORS

Stiff and sharp blades are a necessity to cut paracord cleanly.

YARD STICK OR TAPE MEASURE

YARD STICK OR TAPE MEASURE

Most projects require several feet of paracord, so youll want something longer than a standard ruler to measure it. You can also measure out marks on your workbench for quick reference.

Next page

QUALITY SCISSORS

QUALITY SCISSORS YARD STICK OR TAPE MEASURE

YARD STICK OR TAPE MEASURE