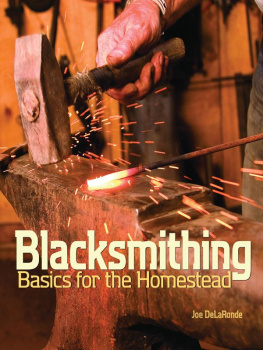

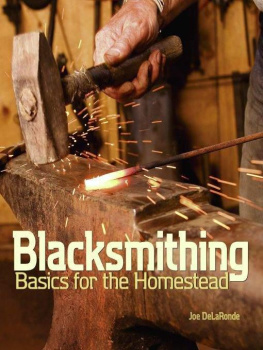

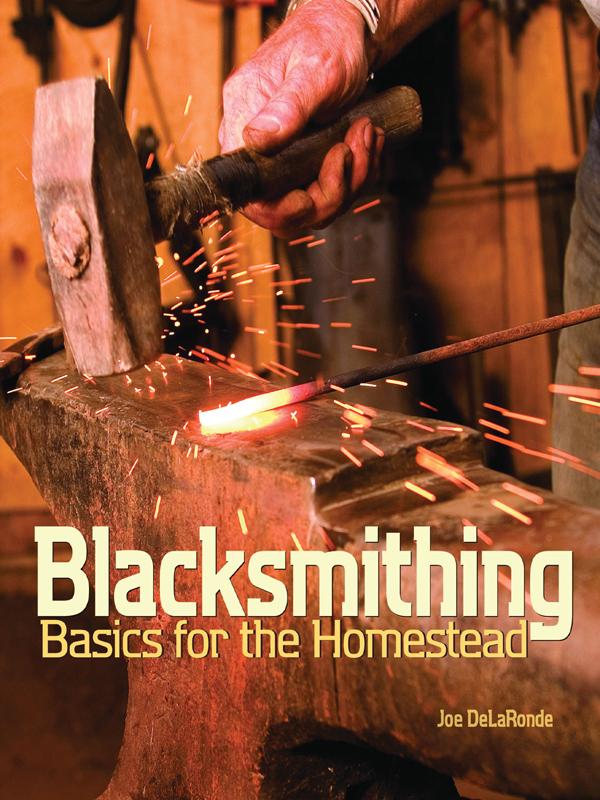

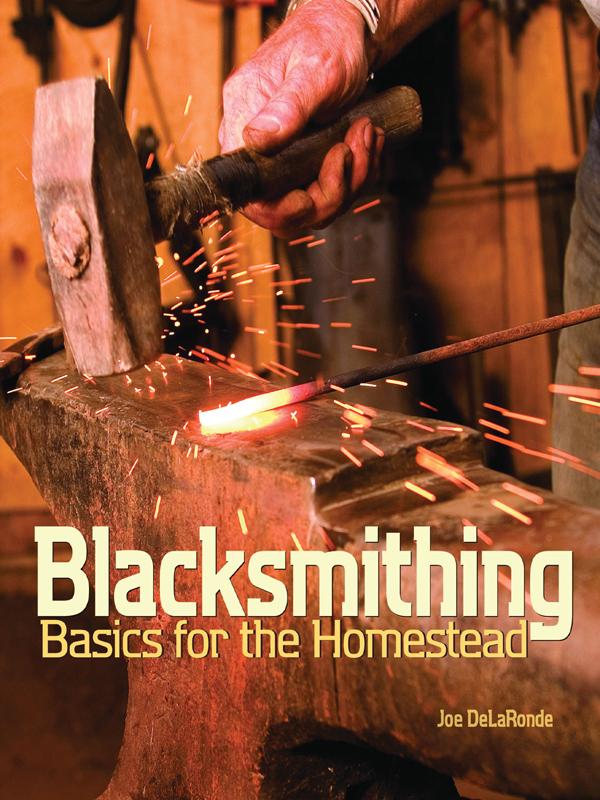

Blacksmithing

Basics for the Homestead

Blacksmithing

Basics for the Homestead

JOE DELARONDE

PHOTOGRAPHS BY JESS LEONARD

First Edition

12 11 10 09 08 5 4 3 2 1

Text and illustrations 2008 Joe DeLaRonde

Photographs 2008 Jess Leonard

All rights reserved. No part of this book may be reproduced by any means whatsoever without written permission from the publisher, except brief portions quoted for purpose of review.

Published by

Gibbs Smith

P.O. Box 667

Layton, Utah 84041

Orders: 1.800.835.4993

www.gibbs-smith.com

Designed by Rudy J. Ramos

Printed and bound in China

Library of Congress Cataloging-in-Publication Data

DeLaRonde, Joe.

Blacksmithing basics for the homestead / Joe DeLaRonde ; illustrations by Joe DeLaRonde ; photographs by Jess Leonard. 1st ed.

p. cm.

ISBN-13: 978-1-58685-706-6

ISBN-10: 1-58685-706-1

1. Blacksmithing. I.Title.

TT220.D43 2008

682dc22

2008003536

WILHELM BILLY VOGELMAN

19031989

Mentor, Friend, and Old-World Craftsman

Contents

I would like to thank my wife, Marlis, for all of her support in keeping this project alive and moving forward and for all of her technical expertise with the computer and editing, without which I would have been lost.

This book could never have been written without my mentor and friend Wilhelm Billy Vogelman, a true old-world craftsman.

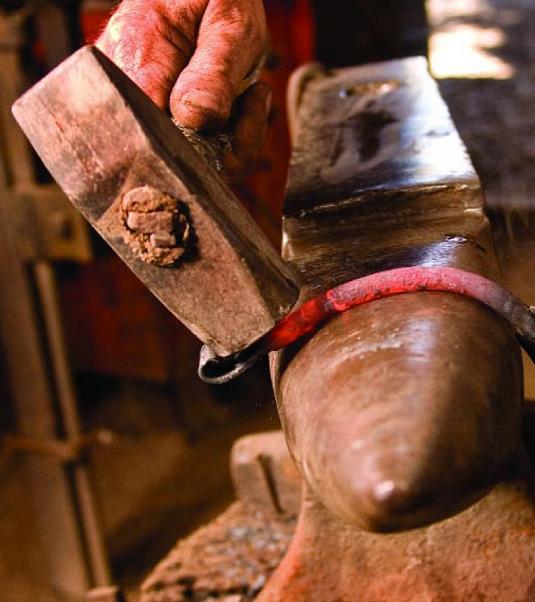

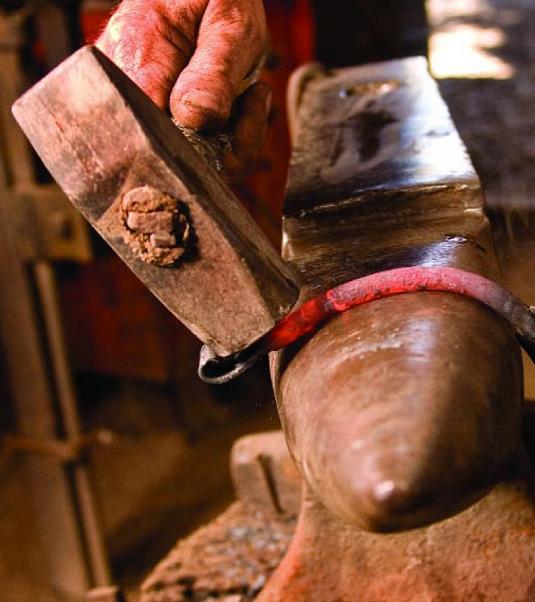

A special thank you to Jess Leonard of Jess Leonard Photography. His pictures of my work are extraordinary and I appreciate his professional skill.

Thanks also go to Mr. Bill Scurlock, of Scurlock Publishing (formerly Rebel Publishing), who was kind enough to release for use in this book excerpts from my chapter in Book of Buckskinning IV (1982).

Last but not least, I want to thank my parents, Gordon and Ann DeLaRonde, for encouraging me to follow my dream.

Blacksmithing is one of the oldest and most important trades from the standpoint of its impact on civilization. It was responsible for bringing mankind out of the Stone Age. Through the years, it has changed the course of history.

Civilizations that mastered and improved on metallurgical technology in its many and varied forms tended to expand, conquer, and subjugate those that did not. The blacksmith, with his coal forge, hammer, and anvil, is the basis for modern technology.

The purpose of this book is to give you the basic blacksmithing skills to become self-sufficient on the homestead, or anywhere else for that matter. The one thing that will keep you tied to and dependent on the settlements, so to speak, is the need for steel tools and accoutrements. Look around the average home and notice everything made of steel: cooking utensils, lighting fixtures, hinges, latches, locks, curtain rods, tables, chairs, hooks, nails, screws, pliers, screwdrivers, hammers, and the list goes on. With a few basic tools and skills, you can make the tools needed to build the homestead, from hammer, nails, chisels, hinges, and latches to amenities such as cooking utensils, lighting fixtures, wall hooks, and curtain rods.

Keep in mind that everything covered here will be done in the traditional mannerby eye. Forget pyrometers, degrees centigrade or Fahrenheit, Rockwell testing, fancy alloy steels, arc welders, and the like. You are about to enter the world of the nineteenth-century blacksmith, where skill and dedication to the craft predate mass production, assembly lines, and the computer age.

Realize that, as with any craft, it will take practice, practice, and more practice. Once you master the basics, it is just a matter of combining basic techniques in a variety of sequences to achieve the finished piece.

There are countless ways of doing any one procedure described on the following pages. Do not hesitate to experiment. You will never know it all, so be open to suggestions and be willing to learn from others. By the same token, dont hesitate to share information with others. After almost 4,000 years of ironwork, there are few secrets.

FACTS, FANTASY, AND OLD WIVES TALES

Next to glassblowing, woodworking, and pottery, blacksmithing is one of the oldest trades in the world. It is also one of the most important and demanding. The blacksmith was called the craftsmans craftsman since he made the tools for the other trades.

Blacksmithing, as near as can be determined, originated in the Caucasus Mountains about 4,000 years ago. As it expanded and became a primary trade, guilds were formed to maintain quality and guard trade secrets. Prior to the 1800s, virtually all trades, including blacksmiths, passed on their training and secrets through the apprenticeship method; there were no textbooks.Very little, if any, written information was available, except perhaps notes and techniques written down by individual smiths. As a result, smiths tended to shroud their trade and individual secrets in mystery, thereby keeping the uninitiated and curiosity seekers from learning some of their more highly prized secrets. It was just good business. If people thought you had a special way of tempering clock springs, you would garner the majority of that type of work in your area. Thus, with no written record, many trade secrets have been lost forever.These secrets were not passed on, for whatever reason, and are now lost.

I worked under William Billy Vogelman, a tenth-generation blacksmith from Emmetsweiler, Germany. He mentioned that his grandfather knew a way to work bronze so it would hold an edge the same way as steel.That trade secret has been lost as well.

Heres an example of how a modern-day secret started, regarding Billys technique for sharpening plow lays.Years ago in the early and mid-1930s, the dust bowl hit the central plains states, including Iroquois, South Dakota, where Billy had his shop. During this time, virtually all the topsoil disappeared, leaving in its wake clay, gravel, or sandy subsoil. On weekends, Billy would drive around the countryside and note where sandy spots or heavy or light clay spots were and which of his customers farmed the various types of soil. By knowing the type of soil, Billy would then know how much suck to put on the plow lay point to keep it in the ground. The other thing that Billy did was to polish the lay in the same direction that the dirt would roll off; thus the lay always scoured clean as soon as it was in the ground.These two factors set the stage for one of Billys secrets. Since plow lay work was one of the mainstays of the rural blacksmith in those days, and since Billy was only a one-man shop, it was inevitable that he would work late into the night, especially during the spring and fall plowing. It wasnt long before Billy started having customers show up from areas farther and farther away because they had heard about his secret method of sharpening plow lays so they would stay in the ground, cut, and scour clean. The combination of knowing the ground, polishing in the right direction, and, of course, working late at night (to hide his secret, or so they thought), created the secret methods and the aura of mystery surrounding his technique. Billy never said he had a secret method for sharpening plow lays, but then he didnt dispel the notion either. After all, he had the lions share of plow lay work in his area.To this day some of the old-timers still talk of Billy Vogelmans secret for sharpening plow lays.

Next page