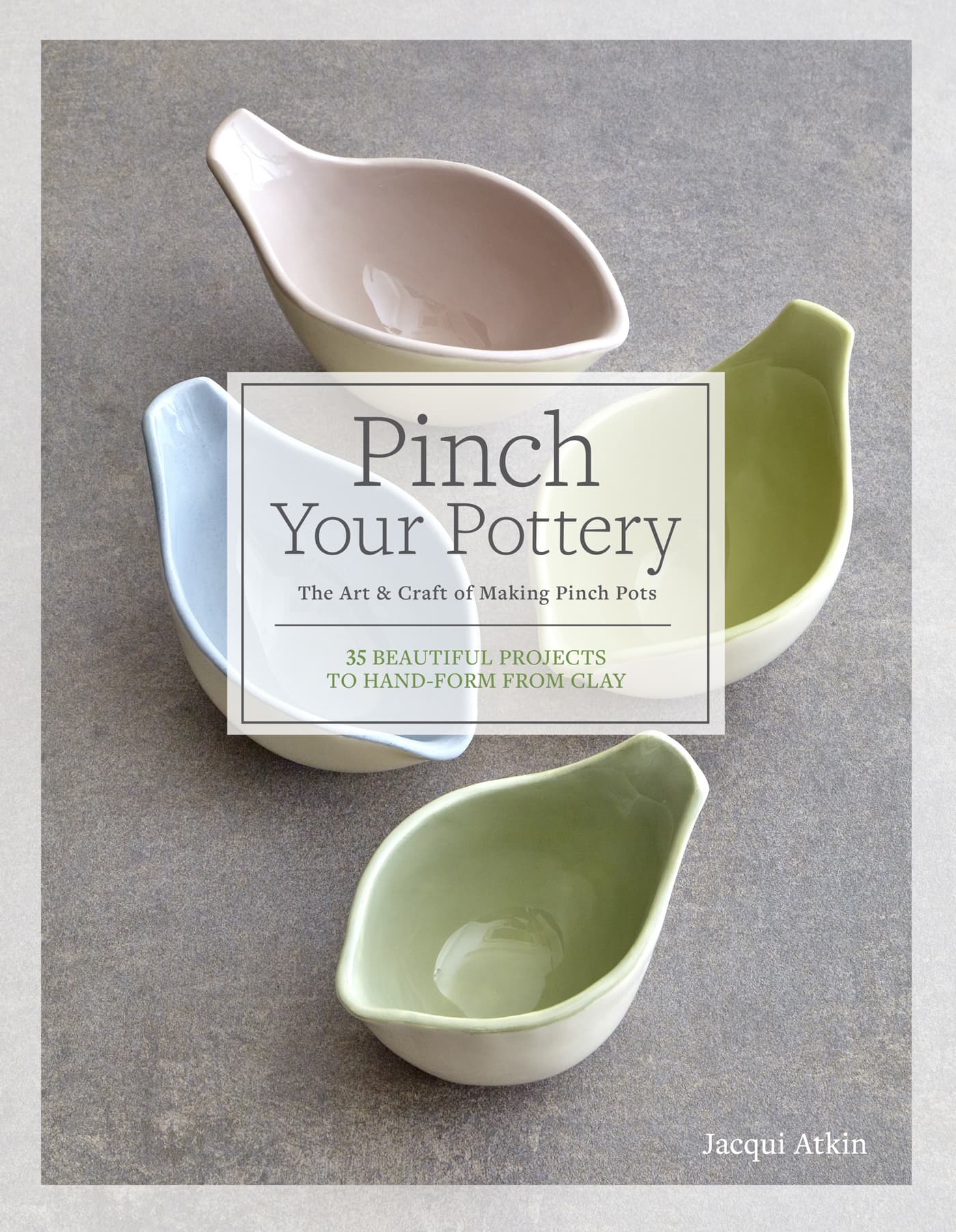

Pinch Your

Pottery

THE ART & CRAFT OF MAKING PINCH POTS

35 BEAUTIFUL PROJECTS

TO HAND-FORM FROM CLAY

Jacqui Atkin

CONTENTS

INTRODUCTION

My sincere hope in producing this book is to dispel any misconceptions about pinching and demonstrate its versatility as a method for making practical and imaginative forms, whether small or large, using mostly your hands, just a few tools, and an electric kiln.

Pinching is the most basic and direct method there is for interacting with clay; its malleable quality instantly makes the handler want to shape it and, in fact, if you give a child a lump of clay without telling them what it is, they will naturally pinch it into something like a bowl or an animal. Do you remember your own first encounter with clay at school? Those lumpen attempts that made your mother so proud. I still have my own childrens early clay artworks, which I treasure for their naivety and the wonderful way they were created without the constraints of technical know-howthey contain much of the character of the child.

In historical terms, pinch pots dating back over 17,000 years have been discovered in China. Their original use was no doubt purely practical, to hold food and water, but at some point their making evolved to produce ornate vessels for wider domestic use and as decorative art forms. This was a technique that laid the foundations for forming clay in other ways and coiling was quickly discovered as a way of extending the size of vessels, but millennia passed before the introduction of the pottery wheel in around 4000 bce, so the pinching technique served humans well for a considerably long time.

In contemporary terms, pinching seems to be a making method thats less well-regarded than others. Maybe this is because of its association with early learning, or possibly that it is seen as a rudimentary technique from which you graduate to other, more technical methods with outcomes of greater sophistication. However, in my experience as a teacher, I have found that many people struggle with the complexities of pinching; they assume it is the simplest method but soon find it has challenges like any other. What I usually say is that mastering pinching will teach the best tactile sensitivity of all the making methods. It is a methodical way of working that allows the individual to make adjustments but gives the best control over the clay. Of course, it takes practice to make something of refinement, but once mastered it is possible to make wonderful, innovative forms for practical or decorative use that rival anything made by other methods, even those on the wheel.

Of course, the process does not end with the making; there is always surface decoration to contend with, an element of ceramics that many find daunting, but again, using just a few basic techniques this book will show there is great scope for individual creativity, including using ready-to-use products for those who dont have the time or space to prepare their own.

Happy Potting.

THE BASICS

CLAYS

Any clay can be used to make pinched forms with practice but some are much easier to work with than others. Traditionally, there are three main categories of clay: earthenware, stoneware, and porcelain, which are differentiated by their fired density and strength. However, more broadly, there are also clays available with wide firing ranges that fall between categories. This alone can complicate the choice, but in addition within each group there are also variables of colours and textures to exacerbate the dilemma. For pinching, the most important factor to consider is the plasticity of the clay, as this will directly influence its handling ability.

POINTS TO CONSIDER WHEN CHOOSING CLAY FOR PINCHING

Firstly, what color clay? It is imperative that you have an idea of what the finished item will look like and this will include how it will be decorated and/or glazed. This decision will determine the color of clay you should use. For example, brightly colored decoration will work far better on a white or pale-colored clay than it would on a dark clay, although the problem can be overcome by applying a layer of white slip.

Secondly, is the form for domestic use or decorative? All clays can be used for domestic wares but earthenware will need to be glazed to make it waterproof. Stoneware clay vitrifies in firing, making it impervious to water; therefore, in theory, any surface treatment is purely decorative.

Thirdly, firing temperature is a serious consideration if firing often: earthenware clays use less energy to fire than stoneware, with porcelain using the greatest amount.

Finally, which type of firing? The projects in this book are fired in an electric kiln, but if at any point the maker wanted to experiment with extreme firing methods like raku or pit, the choice of clay type would be critical as these methods require a grogged, open clay body with good thermal-shock properties for successful outcomes.

TIP

To test for plasticity and working quality, roll a short, fat coil, then bend it into a tight loop. A clay with good plasticity will show no signs of splitting along the bend, but a clay with low plasticity will.

EARTHENWARE CLAYS

These are low-firing clay bodies that generally fire in the range of 1,8302,156F (1,0001,180C).

The most familiar of the earthenware clays is red earthenware, or terra-cotta as it is otherwise known. It is a heavily iron-bearing clay, which gives it its earthy color when raw. It fires to a warm, toasted orange at bisque and brown when covered with transparent glaze. This is a great hand-building clay with good plasticity that can be purchased in smooth or grogged form.

White or off-white earthenware clays are formulated from careful blending of ball clays, china clay (kaolin), and fluxes (materials that influence the melting point of a product). Many are highly plastic and again available in smooth or grogged form, the latter being best for pinching because it has more tooth for joining parts together.

These clays are a good choice for colorful surface decoration and inlay work.

STONEWARE CLAYS

Stoneware clays generally fire in the range of 2,1902,380F (1,2001,300C), and are so called because when fired the clay vitrifies, becoming dense, hard, and impervious like stone.

The range of stoneware clays is the broadest, being available in a whole host of colors, including white, gray, buff, pink, brown, and black, and a wide range of textures. A typical body can be composed of fire clay and ball clay, with varying feldspar content to influence the maturing temperature. Higher feldspar content lowers the required temperature but low-temperature stonewares are often made by substituting the feldspar with a frit. White bodies are made by substituting the fire clay with a lighter version and replacing some of the content with china clay. Stonewares generally have good working properties and plasticity, and many are formulated specifically for use in particular kilns, for oxidized or reduction atmospheres. When buying clay of this type, be sure to check that it is suitable to fire in your kiln.