Contents

Guide

CONTENTS

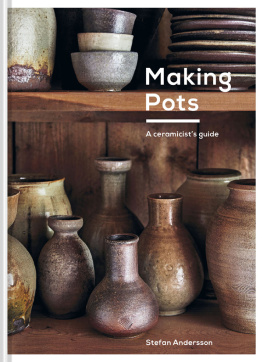

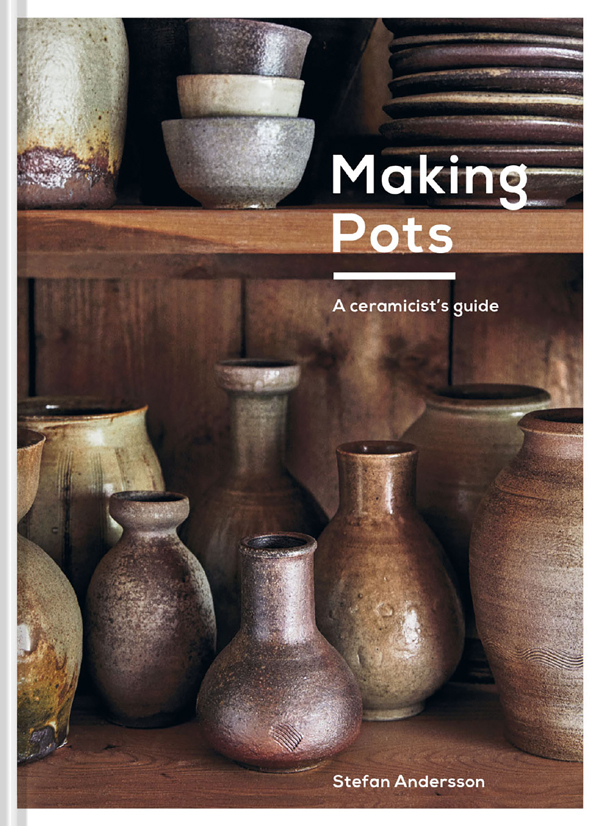

My pottery is located in the little village of Alvik outside Leksand in Sweden. For almost 20 years, the majority of my days have been all about clay and Ive had the opportunity to show my work at galleries, stores and restaurants all over the world. My workshop is in the basement of the house where I live with my family, a good arrangement as it means I can easily look after my pots. One pot might need turning over and another might need covering in plastic to make sure it doesnt dry out too much. On the slope below the house are my kilns and wood stacks and below those is lake Siljan.

I didnt end up here because of a long-standing love for clay. Initially, it was more like an escape from boring university studies, and slowly I realized that the work of a potter suited me. Its a winning combination of hand, head and creativity.

Clay can be many things. For some a laborious livelihood, for others a serious hobby and for some an interest that theres never enough time for. What I like about clay is that it is so pliant, and that it has something to offer everyone.

In this book I will show you how to get started with pottery. Not a lot is required for you to make your first bowl, but at the same time, any of the steps in the process wedging, forming, glazing and firing can go wrong and youll have to start all over again. Frustrating, possibly, but at the same time its greatest charm. A craft to grow with.

Stefan Andersson

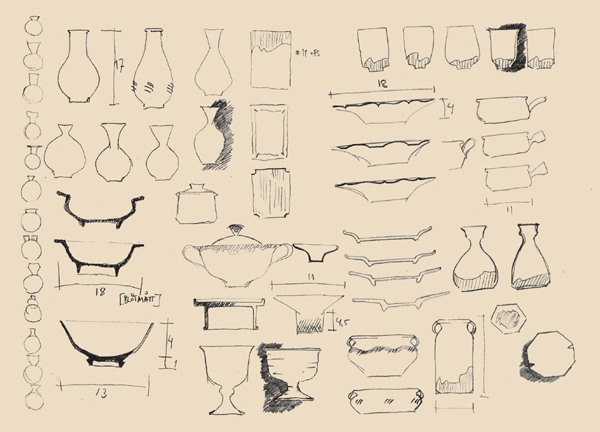

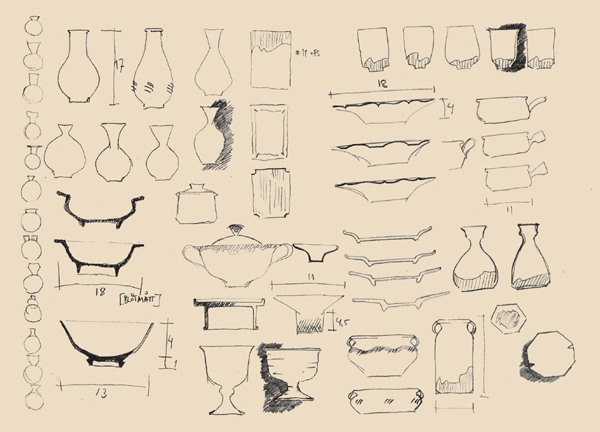

In earlier times, potters had no choice but to use clay from a nearby field. Designs were determined by how pliable the clay was, any decoration was a result of the forming technique and firing was fine-tuned to prevent cracks, blisters and breakages. With limited means, it was possible to make good pots that easily measure up to todays standards, in terms of both user-friendliness and design.

For those outside the pottery world, porcelain is the only clay there is, but a potter divides clay into three different groups earthenware, stoneware and porcelain. They are all made from weathered rock, and share many other characteristics. The classifications exist mainly to help us decide to what temperature they should be fired.

Earthenware clay is darker and naturally easy to work with. This is due to it having travelled a long way from its origins, accumulating soil, organic material and other particles along the way.

Porcelain clay on the other hand, is relatively pure resulting in its white colour. It is often regarded as difficult to work with, as its more delicate and unstable on the wheel, but its just different to work with (and requires some adjustments to the techniques used).

In between these two groups we find stoneware clay, which comes in many different varieties.

An important thing to note about the different characteristics of the three groups is that earthenware is fired to a temperature a couple of hundred degrees lower than stoneware and porcelain. As a rule, earthenware clay is difficult to make waterproof, while porcelain and stoneware are, in principle, completely waterproof after firing.

Plasticity is the clays ability to stretch and bend. A clay with high plasticity, for example, is good for throwing since it can be stretched without cracking, while a clay with less plasticity is better for rolling and for making larger objects. The appearance of many older pots from the 19th century and earlier can tell us about the limitations of the local clay, whether it had low plasticity or impurities, for example.

Today we rarely work with clays taken straight from the ground, and the distinctions between earthenware, porcelain and stoneware are becoming more and more blurred. Instead, clays are produced by mixing many different ingredients together so that suppliers can provide reliable clay again and again. This has also opened up the possibility of making earthenware clays that can be fired to higher temperatures and novelties such as black porcelain.

By adding a substance called grog (fired and ground clay), clays can be altered further to develop different characteristics.

The use of grog is likely to have begun with the first broken pot and gives the clay sturdiness and durability. Depending on how coarse the grog is, the clay will become more or less suitable for different forming techniques. Clays come in various grog grades.

Many pottery studios and schools choose not to use both earthenware and stoneware together. The risk is that earthenware is accidentally fired to the higher temperature that is used for stoneware, which can lead to severe damage to the kiln. If you are experimenting with different types of clay, best practice is to fire smaller samples on a shelf that you arent precious about, or perhaps in a bowl that you dont like so much.

Four clays that I use in my work. At the top is a stoneware clay that contains iron and a little bit of sand. To the left is a reliable white stoneware clay. To the right, a coarse-grogged natural stoneware clay. The grey colour comes from the high concentration of organic material in the clay. At the front is a dense white porcelain clay that turns transparent in the kiln.

) often prefer a coarser grade. But there are exceptions, and one of my most popular cups is thrown in a clay with 0.5mm grog. This gives a body (see image caption) with a lot of character, but my fingertips need days to recover after throwing, to get their fingerprints back.

Those who are more observant will note that theres a difference between one grog and another. Some grogs are like crushed rocks while others can be smooth like sand. Each will contribute something, adding a specific characteristic during the production process, giving small contrasts in both colour and structure after firing.

In all cultures there are examples of potters adding organic material to clay to improve its quality. A common additive used to be animal manure. A modern version is to mix in paper pulp. Just a small addition of paper makes the clay a lot stronger, which means that large objects can be moved and dried without them cracking. I mix sawdust into my larger pieces to prevent cracking, but fibres such as cotton or reed also work well.

Most distributors sell different types of ready-mixed paper clay. These clays contain a significant amount of paper, giving them some exciting qualities, the main one being that its possible to add fresh clay to already dried clay without them cracking.

Making your own paper clay is easy, but dont make more than you need, as it gets mouldy quickly.