trash-to-treasure papermaking

trash-to-treasure papermaking

// make your own recycled paper from newspapers & magazines / can & bottle labels / discarded gift wrap / old phone books / junk mail / comic books / and more

Arnold E. Grummer

The mission of Storey Publishing is to serve our customers by publishing practical information that encourages personal independence in harmony with the environment.

Edited by Deborah Balmuth and Nancy D. Wood Art direction and book design by Dan O. Williams Photography by Greg Nesbit Photography, except for pages 10, 12, 13, 15, 97, 207 courtesy of the author; 75 (scrap paper), 176 by Mars Vilaubi Indexed by Nancy D. Wood

2011 by Arnold Grummer

All rights reserved. No part of this book may be reproduced without written permission from the publisher, except by a reviewer who may quote brief passages or reproduce illustrations in a review with appropriate credits; nor may any part of this book be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical, photocopying, recording, or other without written permission from the publisher.

The information in this book is true and complete to the best of our knowledge. All recommendations are made without guarantee on the part of the author or Storey Publishing. The author and publisher disclaim any liability in connection with the use of this information.

Storey books are available for special premium and promotional uses and for customized editions. For further information, please call 1-800-793-9396.

Storey Publishing

210 MASS MoCA Way

North Adams, MA 01247

www.storey.com

Printed in China by R.R. Donnelley

10 9 8 7 6 5 4 3 2 1

Library of Congress Cataloging-in-Publication Data

Grummer, Arnold E., 1923

Trash-to-Treasure Papermaking / By Arnold E. Grummer.

pages cm

Includes bibliographical references and index.

ISBN 978-1-60342-547-6 (pbk. : alk. paper)

1. Paper, Handmade. 2. Papermaking. I. Title.

TS1124.5.G78 2011

676'.22dc22

2010043056

contents

Chapter 1 Fiber Art

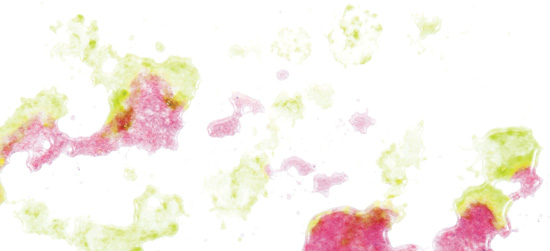

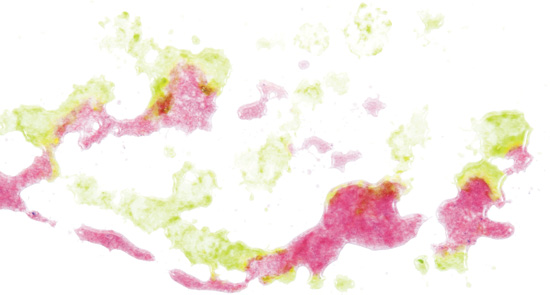

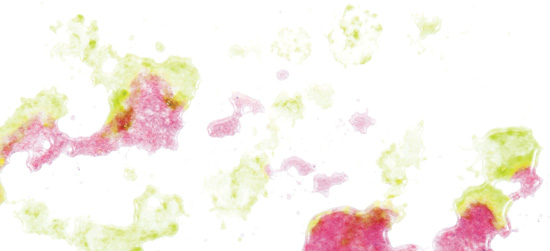

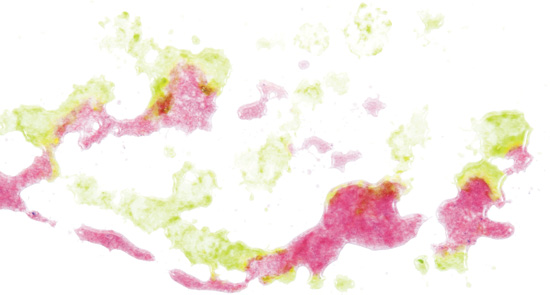

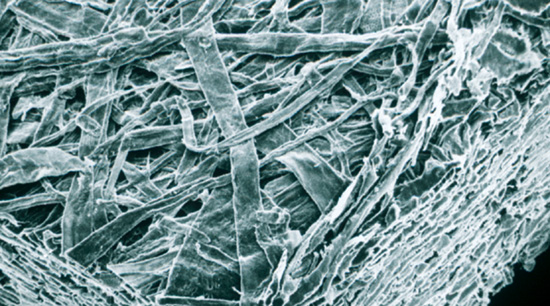

Where does paper come from? As you read these words, it appears as though the paper theyre printed on is a fairly solid, unchanging object. But if you look more closely at the paper, through a magnifying glass or microscope, you may be able to see that this thin sheet of paper is actually made up of multiple layers of tiny fibers that have bonded together naturally. In the process of making paper, batches of single fibers are laid down into a thin, even mat.

So, you are holding a batch of little fibers. Across the fibers backs, we have put ink in certain patterns. Behold, you and I can communicate!

The Nature of Plant Fibers

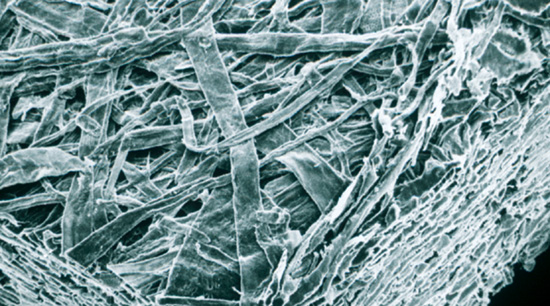

Paper fibers are cellulose. They are produced by everything that grows, from mighty trees to fungus and algae. Some people believe they are the most abundant thing on the face of the earth. The fibers used in papermaking are tiny: If you have very fine hair and were to cut off a piece, you would have something like a paper-making fiber.

Even though its tiny, a cellulose fiber is hollow, like a drinking straw. If the cut surface of a tree stump were magnified a hundred times, you would be able to see all the little open-ended fibers lying side-by-side. Most fibers flatten out when made into paper, but some retain the hollow center.

Starting from Scratch

The first thing a commercial papermaker needs is processed fibers. In a process called pulping, all the cellulose fibers are forced loose from each other. Separating fibers is not easy. They hang together very strongly and must be separated using a grindstone, chemicals, or both.

In this magnified photo, you can see the many layers of fibers that make up one thin sheet of paper.

Once the fibers have been separated, they are floated in water. This way, the papermaker can control where the fibers go and what they do. The fibers will go where the water goes. The papermaker keeps them separated in water and then pours the water onto a sieve with a rim around it. The rim channels water onto the sieve so it doesnt run off the sides. As water runs through the sieve, the single fibers are caught on the surface. That is how a paper-maker lays down millions of little fibers in a thin, even mat.

The cellulose fibers that make up a sheet of paper are held together by a natural bond that happens when fibers touch each other in water. Very weak when formed, the bond grows stronger as water is taken away. The more water that is taken away, the stronger the bond becomes. When totally dry, the fibers are joined in a new sheet of paper.

Pulping Fibers

In the early days of papermaking, fibers were often ripped apart by stamping or grinding plants while wet. Sometimes the plants were soaked first in lime pits or water in which ashes had been soaked. Early grinding was done with a mortar and pestle. Later, machinery was developed. Today, your newspaper is made with fibers ripped apart by forcing a length of log against a grindstone. The fibers are then called groundwood pulp. Also, fibers can be obtained from trees and other plants by the use of chemicals or a combination of chemicals and grinding.

Next page