Other titles in the series: |

| Reeds Outboard Motor

Troubleshooting Handbook

Barry Pickthall

ISBN: 9781408181935 |

| Reeds Skippers Handbook

For sail and power

6th edition

Malcolm Pearson

ISBN: 9781408124772 |

| Reeds Crew Handbook

For sail and power

Bill Johnson

ISBN: 9781408155714 |

| Reeds Knot Handbook

Jim Whippy

ISBN: 9781408139455 |

Copyright Barry Pickthall 2013

Published by Adlard Coles Nautical an imprint of Bloomsbury Publishing Plc

First published by Adlard Coles Nautical in 2013

This electronic edition published in 2013

Bloomsbury Publishing Plc

50 Bedford Square, London, WC1B 3DP

www.adlardcoles.com

ISBN 978-1-4081-8192-8

EPDF ISBN 978-1-4081-9258-0

epub ISBN: 978-1-4081-9257-3 (e-book)

All rights reserved. You may not copy, distribute, transmit, reproduce or otherwise make available this publication (or any part of it) in any form, or by any means (including without limitation electronic, digital, optical, mechanical, photocopying, printing, recording or otherwise), without the prior written permission of the publisher. Any person who does any unauthorised act in relation to this publication may be liable to criminal prosecution and civil claims for damages

The right of the author to be identified as the author of this work has been asserted by him in accordance with the Copyright, Designs and Patents Act, 1988.

A CIP catalogue record for this book is available from the British Library.

Designed by Kayleigh Reynolds/PPL Ltd

Note: while all reasonable care has been taken in the publication of this book, the publishers take no responsibility for the use of the methods or products described in the book.

Sign up for newsletters to be the first to hear about our latest releases and special offers

Contents

Diesel engines are simpler and safer, as well as being more economical and efficient, than petrol engines. They are at their most efficient when operating at a steady rate, and because they work under high compression, their parts are more robust, which makes them ideal for marine uses.

Regular maintenance is key to reliability. The last thing you want to be doing is crawling around the engine bay when out on the water, so this pocket companion has been written to highlight the regular checks and maintenance needed before and after each trip to keep your diesel engine running as it should.

But if there is a breakdown, this book, which should always be read in conjunction with the engine handbook, offers a simple guide to troubleshooting and provides clear step-by-step instructions to get you going again.

The diesel engine uses the heat generated by compressing air to ignite fuel sprayed into the combustion chamber through high-pressure injection nozzles. This contrasts with the petrol engine which uses a spark plug to ignite the air/fuel mixture and operates at a much lower compression.

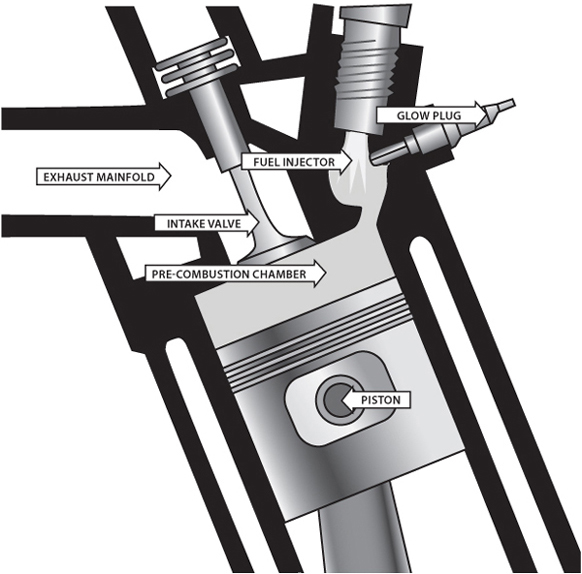

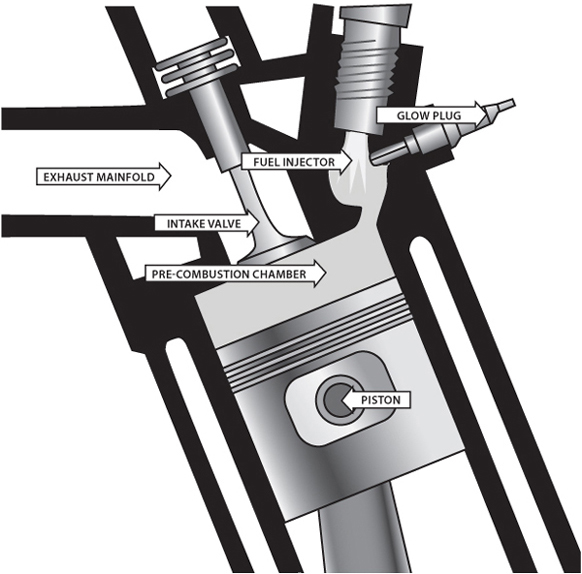

Modern lightweight marine diesel engines are a far cry from previous generations. Engines pre-dating the 1990s, when the electronically managed units first came to prominence, relied on fuel and air being mixed in a pre-combustion chamber before injection into each cylinder. The mixing and injection steps were controlled mechanically, which could never match the fuel/air mixture for both fast and slow running. As a result, the fuel burn was often incomplete, particularly at low speeds and fuel wastage and emissions were always high.

Early diesel engine configuration

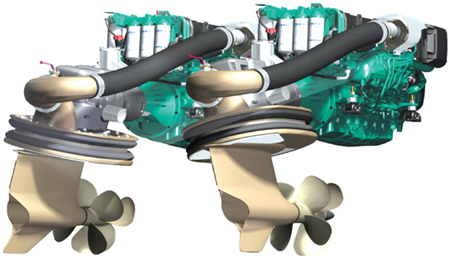

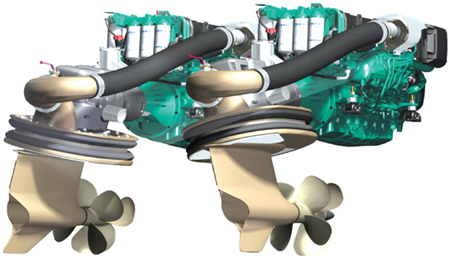

A Volvo Penta D6 400 lightweight diesel engine equipped with direct injection, an electronic management system and turbocharger.

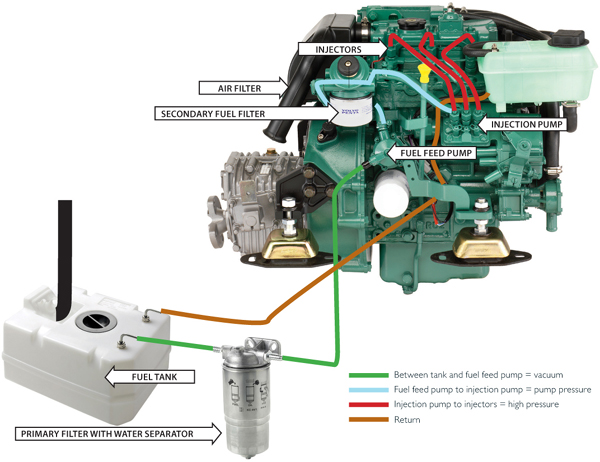

The latest diesel engines are managed electronically with ECMs (Electronic Control Modules) and EDCs (Electronic Data Controls) delivering precisely the right amount of fuel the instant it is needed, as well as moderating everything from engine speed and load, piston position, coolant and oil temperature. Fuel is now burned far more efficiently, delivering more power, greater fuel economy, and far lower amounts of carbon dioxide, carbon monoxide, and unburned hydrocarbons.

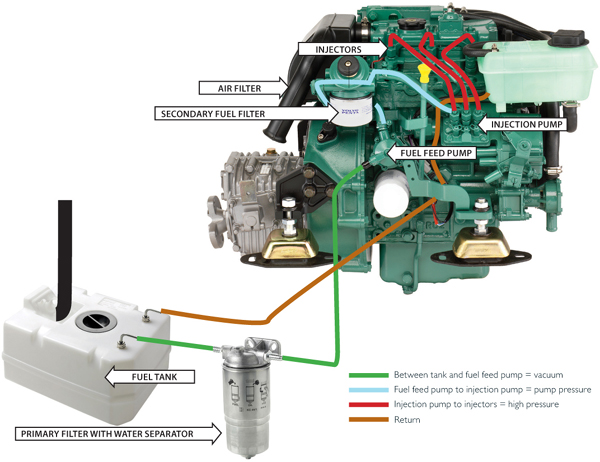

The fuel injection pump pressurises fuel into a delivery tube called a rail, and keeps it under constant pressure of 23,500psi or higher, ready for when the ECM determines exactly when and how much fuel is to be sprayed through injectors into each cylinder.

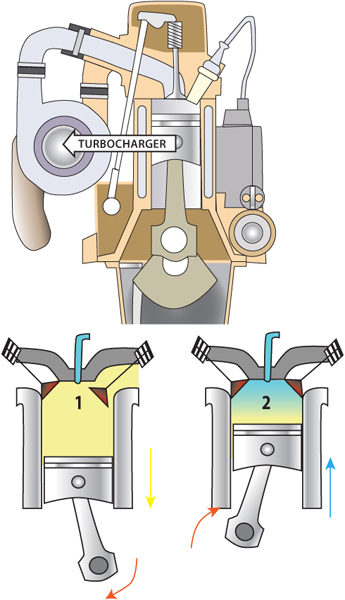

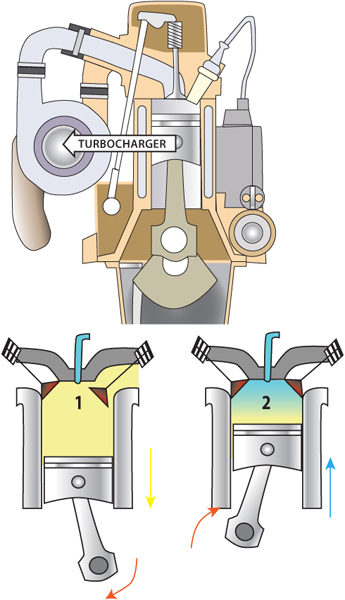

With naturally aspirated engines, the air comes through a filter similar to those on petrol engines. Performance orientated diesels are fitted with one and sometimes twin turbochargers designed to ram far greater volumes of air and spent exhaust gases into the cylinders. These turbochargers not only increase power output by 50 per cent or more, but can also improve fuel economy by 2025 per cent.

FOUR-STROKE DIESEL ENGINE CYCLE

1. INDUCTION

The intake valve opens; the piston travels down and draws air into the cylinder.

2. COMPRESSION

The piston travels back up; the highly compressed air rises in temperature.

3. IGNITION / EXPANSION

The diesel fuel injected before the top dead centre spontaneously ignites on contact with the air. The expansion of the gas pushes the piston toward the bottom dead centre.

4. EXHAUST

The exhaust valve opens; the piston travels back up and expels the burnt gas.