First published in 2008 by The Crowood Press Ltd, Ramsbury, Marlborough, Wiltshire, SN8 2HR

www.crowood.com

This e-book edition first published in 2013

Nigel Burkin 2008

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

ISBN 978 1 84797 532 4

Contents

| ac | Alternating current. |

| AWG | American Wire Gauge. |

| BNSF | Burlington Northern Santa Fe Railway a US Class 1 railroad company. |

| CTC | Centralized Traffic Control a US-based signalling system. |

| CV | Configuration Variable (decoder programming slot). |

| dc | Direct current. |

| DCC | Digital Command Control. |

| DPDT | Double pole, double throw switch. |

| DRS | Direct Rail Services. |

| EMD | Electromotive Division builder of the European-operated Class 66 and locomotives used in the USA. |

| EWS | English, Welsh and Scottish Railway. |

| F1 to F6 etc. | F stands for function (there may be as many as twenty-eight functions that can be controlled by a throttle). References to function button numbers may be prefixed with the letter F in DCC instruction manuals. |

| GBRf | GB Railfreight, a First Group company. |

| GE | General Electric a US-based locomotive builder. |

| HEX | Hexadecimal. |

| LCD | Liquid crystal display. |

| LED | Light emitting diode. |

| MOROP | Union Europenne des Modlistes Ferroviaires et des Amis des Chemins de Fer (European Union of Model Railroad and Railroad Fans). |

| MRC | Model Rectifier Corporation. |

| MRL | Montana Rail Link. |

| NEM | des NEM du MOROP NEM standards. |

| NMRA | National Model Railway Association. |

| PCB | Printed circuit board or copper laminated circuit board. |

| RPs | Recommended Practices. |

| RTR | Ready-to-run. |

| SMT LED | Surface-mount LED. |

| TOPS | Total Operations Processing System. |

| USP | Uninterruptible Signal Processing. |

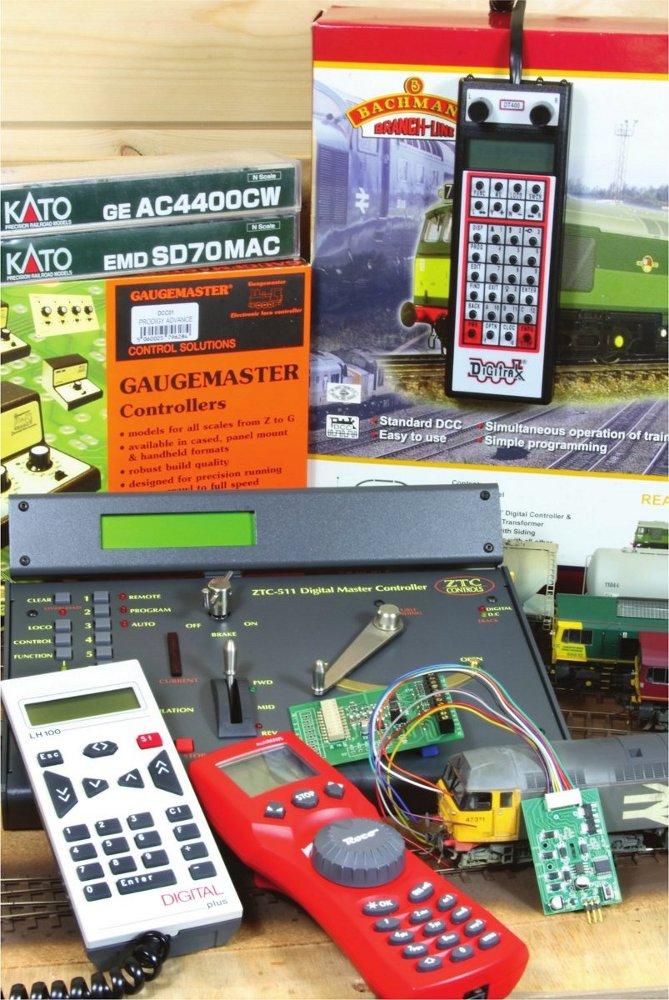

| ZTC | ZTC Controls a UK-based DCC equipment manufacturer. |

This book is dedicated to my ever loving and supportive wife, Sarah.

I am indebted to the following for their kind assistance with the production of this book. They have helped with practical advice, proofing for technical content or have contributed equipment featured in the projects.

Alan Murray of MacKay Models.

Stanley Kerr of MacKay Models.

Dennis Lovett of Bachmann Europe Plc.

John Jewitt of Sunningwell Command Control.

David Nicholson of ZTC Controls.

Charlotte Nicholson of ZTC Controls.

Robin Hamp of Express Models.

Ian Fowler of Gaugemaster Controls.

Diana Johnson of Tumuli Design for illustrations and photography.

A special acknowledgement to Pete Lawrenson, Chief of Security and Safety, together with Ben Hampson of Montana Rail Link for their kind assistance with my research into US locomotive operations.

And finally, to Steve Jones of Telford, Shropshire, a well-known DCC enthusiast, for dropping me into all of this DCC stuff in the first place!

Were all beginners at something at some stage in our lives and Digital Command Control (DCC) remains something of a mystery for some modellers (including myself at one time). Although there are many that would like to take the plunge, technology and cost can be barriers to adoption, even though it is becoming generally accepted as an exciting technology that brings added realism to the operation of a model railway. In this book I offer a practical introduction to DCC, accompanied by a variety of projects that can be followed and adapted to suit almost any situation.

There is little doubt that DCC is growing in popularity in the UK and the introduction of accessible entry-level and mid-range sets from Lenz, Bachmann, Gaugemaster and Hornby will help the modeller teetering on the cusp of transition to make the change. I was a convert to DCC in 2001 following a couple of years of my own brand of indecision: humming and hawing over the cost, the perception that DCC is complex and what the potential benefits may or may not be. Having made the decision to go digital after trying it on a friends loft layout, in July 2001 I purchased a Digital plus Compact system by Lenz Elektronik GmbH with a handful of decoders. It was a major purchase for me and one that was very carefully considered. Five years on and I wonder what the fuss was all about!

The rationale behind my decision to go digital needs to be explained. The construction of the first of my two (then) new exhibition layouts, Dudley Heath Yard, was followed by an intense session of wiring and control panel construction to equip it with cab control to work with a pair of KPC hand-held controllers. The layout was a compact end-to-end design with a scenic section of 8ft supported by 4ft of fiddle yard. To obtain the operational flexibility for shunting and train operation, the layout was divided into nine sections controlled through double pole, double throw (DPDT) switches to enable dual control. In addition, there were six isolation sections for locomotive stabling. Two separate transformers were required to enable trouble-free operation with the pair of hand-held controllers and common return wiring. This project evolved into an exercise in spaghetti and soldering. Controls for points, signals and trains were grouped together on one control panel that took many weeks of careful work and testing to complete. I now realize that DCC would have saved me a considerable amount of work; but it did not save the layout it was scrapped when its shortcomings were laid bare by the adoption of DCC and the difference in approach to operation together with layout design.

As structural work on my second and more successful layout, Platform 4a & 4b, progressed, I was faced with a smaller version of the same wiring exercise and this led to a pause in the track and electrical planning process. How could I get the much needed operational flexibility from a layout with a scenic section measuring a mere 8ft in length without resorting to so much wiring? Good question!

At about the same time, I was toying with dc lighting systems, having purchased a couple of kits from Express Models, particularly orange door lock lights for multiple unit stock. Whilst the systems work well, my research into DCC and decoders showed that there is a simpler and less costly route for locomotive and rolling stock lighting, one that would eliminate batteries and recharging from the equation, but with some different practical difficulties. All of these issues came together at about the same time and required a definitive solution before costs got out of control. Although battery- or capacitor-supported lighting systems offer constant lighting for dc (analogue) operation, the cost of installation became fairly prohibitive. I needed to increase the dynamics of the layout for exhibition use and to increase the play value for me, together with interest for the viewer. By all accounts DCC offered the most sensible solution to my layout control conundrum.