Page List

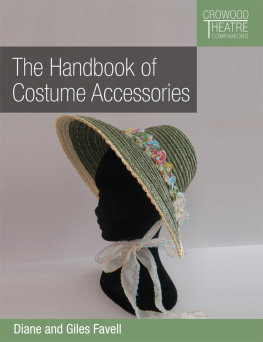

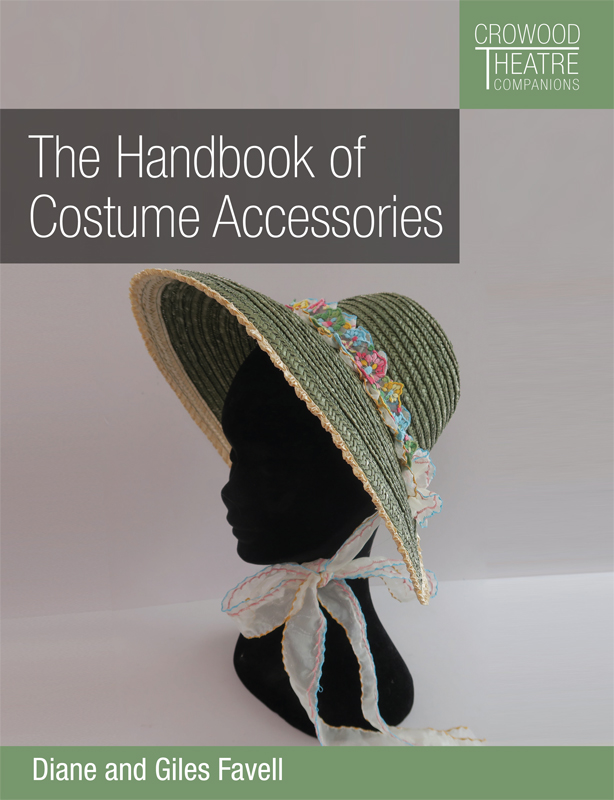

First published in 2023 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2023

Diane Favell and Giles Favell 2023

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 0 7198 4156 9

Cover design by Maggie Mellett

INTRODUCTION

In theatre, a costume prop is perhaps best defined as a costume accessory such as a brooch, glasses, watch, cane, crown, hat and so on. In practice, there is sometimes a crossover of responsibility with the props department on some items depending on how the props are used. The wardrobe department and the props department also have differing skills and equipment available, so a reciprocal cooperation can also be very beneficial.

Traditionally, costume props have been so often magically produced from carefully guarded boxes and drawers by supervisors who have collected them over many years. Many may be originals, others well-made props made for specific shows long past but all have had their future usefulness recognized, and been placed in safe custody.

In years gone by, a morning spent at the local flea market, local junk shops and the like were good sources of period pieces. Nowadays, online auction sites seem to have taken over rather more, which involves more time for delivery and sight-unseen purchases however, there is undoubtedly a greater range of choice available, though many cheap finds may need a bit of work to produce an authentic look.

The changing world has brought other advantages to us as well. We can buy very cheap but credible jewellery components from the Far East over the internet and, very importantly, we can manufacture our own pieces using affordable desk-top machines if we are so inclined. This new approach opens the door to producing our own designer props in-house, or at least knowing how it can be outsourced. It should be remembered that the new skills learned are never wasted and are very satisfying to learn.

The subject being so very broad, this book can only show a very limited cross-section of examples and techniques that, of course, can be applied much more broadly with imagination. We have in some instances shown the use of (desk-top) CNC (computer numerically controlled) machines in order to demonstrate how they may be used effectively. The same props can, of course, be made using conventional tools and techniques. The idea is to fire the imagination, rather than to prescribe their use.

In this book, we have touched on some ancient skills, though we have tried to concentrate on tools and equipment that you may have (or can get quite cheaply) in the home or, if you havent, maybe you know (or can find) someone who has. The new technologies emerging and coming into our homes through domesticating the machines are many and vast, though some basic skills in the manufacture of costume props will ensure good use of these technologies and an appreciation of authentic appearance.

We hope to bring you our combined, many years of experience in the manufacture and use of these items and, although we are merely scratching the surface of the vast subject of costume props, we hope that this may lead to an increase of interest in the skills and, hopefully, sow a seed for the furtherance of a lifetime hobby or career, such as we have had (and are having).

WORKSHOP TOOLS AND EQUIPMENT

In recent years we have become extremely fortunate that technologies that were just science fiction fifty years ago are now available to us domestically and that benefits small workshops too.

Laser Cutting

One of the most dramatic is perhaps the laser first successfully built in 1960, and developed over subsequent decades, lasers come in very many forms, but first came into our homes in any quantity built into CD players from the early 1980s. These were diode lasers cheap and small a far cry from the original ruby laser, and the gas lasers also developed.

A laser differs from other light sources in that it emits light coherently. This can be used in a number of different ways. For instance, spacial coherence can allow a laser beam to stay narrow over large distances, enabling such devices as laser pointers, or spacial coherence may allow the beam to be focused on a tight spot, allowing cutting and lithography.

1965 saw the very first laser cutter, built to drill holes in diamond dies and heaven knows at what cost! The early 1970s enabled production of CO2 lasers to cut such materials as textiles, as CO2 lasers were not yet powerful enough to overcome the thermal conductivity of metals.

By the 1980s, there were more than 20,000 metal-cutting lasers in the world, and their numbers and abilities were increasing however, they were a very significant investment, as was the control element that enabled them to be used.

Fast-forward to today it is now possible to buy a 40W CO2 laser from China for under 400, which may cut materials up to 5 or 6mm thick. Also available are 10W diode lasers that will cut up to 6mm.

If you wanted to buy a laser, what would you choose and why? Well, first, it depends what you want to do.

A laser can etch and it can cut, and it is one of the fastest processes of doing so. It can cut paper, card, wood, acrylic, fabric, leather, and large industrial machines can even cut metals steel up to 15mm thick! Many other materials can be etched, including stone, glass and some metals, even with hobby machines.

If you are a large concern and want to make an income from selling or making lasered products, then you will need a very capable, fast machine. In very simplistic terms, to cut through a material, you can either pump a small amount of energy into it and go slowly, or you can pump a lot of energy into it and run faster (this is very simplistic it can be a lot more complicated than that). Therefore, if you need speed, you would need a high-powered machine, such as a large CO2 laser, which can cost a fair bit. If you are simply doing bits and pieces for yourself, speed is not likely to be such a concern and, therefore, either a small CO2 or a diode laser may well be the most appropriate.

A CO2 laser consists of a fairly large, lidded box with a work-bed at the bottom, and an enclosure at the back that houses (among other things) the static glass CO2 tube, which generates the laser beam. The (red) light beam is then bounced sideways and forward off angled mirrors some of which are travelling on computer-controlled linear rails to finally bring the beam down on to the workpiece to be cut. CO2 lasers also require cooling. The normal method is to have a water tank or often a water chiller under the machine, with a circulating pump, which keeps the CO2 tube cool when it is powered up.