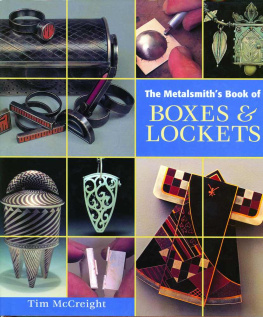

Metalsmiths Book of Boxes and Lockets

Tim McCreight

Copyright 2015

Brynmorgen Press

Brunswick, Maine

ISBN for this digital edition: 9871929565764

First published by Hand Books Press in 1999

All rights reserved. Artwork in this publication is protected by copyright and may not be reproduced in any form without permission of the artist. No part of this publication may be reproduced or transmitted in any form without prior permission from Brynmorgen Press.

Introduction

What is it about boxes that draws us to them so irresistibly? We admire jewelry or candlesticks by looking, but were compelled to pick up a box or locket and open it. Perhaps its the toy-like action of a catch and hinge, or the mystery of wondering what might be inside. Perhaps our fascination comes in part from other experiences of boxes, a universal memory of childhood treasures in shoe boxes and tobacco tins.

Lockets and boxes offer a wonderful format for metalsmiths. Technically, they call upon a set of skills that can challenge anyonehinges that slide fluidly, seams that disappear, catches that click with confident assurance. Mastery of these construction techniques is not only a reward in itself, but a valuable aid in other metalworking activities. The ability to make a neat hinge requires skills in measuring, soldering and fittingall useful for stonesetting, surface decoration and other techniques.

The Metalsmiths Book of Boxes and Lockets divides the topic into its constituent parts: the box, the hinge, and the catch. This allows for a creative Mix-and-Matchthink of childrens books that are slit to allow each page to be a reconfigured creature. Select a box technique you want to try, match it with a hinge that you think will complement the box, then select a catch to complete the piece. Of course this book cannot cover all the thousands of options in each of these categories, but in this way Ive tried to create a structure that is clear without being narrow. The chapters on Boxes, Hinges, and Catches are followed by a short chapter on Basics & Practices that provides instruction in soldering, tube making, and other general topics that apply to making boxes and lockets.

So, take a hinge from here and a catch from there, and while youre at it, make up your own variations. Season this information with the exciting work shown here and synthesize these ingredients into objects that are as satisfying to use as they are to make.

Note for the Digital Edition

This book features more than a hundred examples of boxes and wearable containers from talented metalsmiths around the world. In the original volume these images were merged with the text but in this digital format the presentation is made clearer by placing them all together after the text. In all cases the designs belong to the original artists and should not be copied.

Metalworking Safety

Safety in metalworking depends on adhering to the following principles:

- Common sense

- Knowledge and respect for the machines

- Common sense

- Avoiding dangerous materials and processes

- Common sense

- Protecting yourself from invasion by particles, fumes and sharp objects

Because everyones body is unique, even officially tolerable levels of a chemical may be intolerable fo you. Pay attention to the early signs your body sends: If you have a dry mouth, an odd taste, a rash, nausea or dizziness, stop what youre doing and take a break. Systematically eliminate procedures in order to identify the source of the problem. As a creative person, you will then be able to come up with an alternate approach.

Any time you work near a motor-driven tool there is a danger of getting snagged. Always keep hair and clothing tied back out of the way when drilling, buffing and grinding. Always wear goggles. When grinding or buffing with a machine, be certain the dust is directeed away from you, and use a respirator if working for more than a few minutes. Be especially careful to avoid breathing toxic materials like bone, antler, metallic gem material (e.g., malachite) and exotic woods.

Minimize the use of strong solvents when possible. Label all chemicals and store them in a safe place in an appropriate container. Wear rubber gloves, spash-proof goggles and an apron.

Fire is an integral part of metalworking and a good metalsmith is comfortable with flame. But comfortable doesnt mean careless. Always use the soapy water test after attaching a regulator and replace the tank if there is a problem. Sniff the air when you enter the studio and exit immediately if you smell gas.

Never set combustibles like paper towels or drawings on a soldering table and always quench charcoal blocks after use.

Repeated actions such as hammering can trigger Repetitive Strain Injuries (RSIs) such as carpal tunnel syndrome and similar disorders. Get in the habit of shaking out your hands every ten minutes or so and stop work if your fingers are numb or tingly. It is often possible to adjust position and angles to correct these problems.

Relevant Techniques

This chapter is a kind of information warehouse advice and options that relate to many of the techniques described throughout the rest of the book. For example, almost every process described in the preceding pages involves soldering, so here youll find information about soldering tools and tricks. Because tubing is so important, this section will tell you how to make it, cut it, and size it. And then thereswell you get the idea.

Soldering Methods

The most common and obvious way to solder is to set the fluxed components together, lay a small piece of solder across the joint and heat it up. As a rule of thumb, simpler is better, so this method is my first choice. But sometimes more is needed.

When pieces will not stay together by themselves it might be necessary to tie them together with wire. The best material for this is annealed blackened steel called binding wire, available from jewelry supply companies. Galvanized steel wire from a hardware store can be used, as can nickel silver wire, but these are harder to bend around the pieces.

Joining irregular shapes may require a little more forethought. Generally, figure out clearly the lines of tension that are neededwhere exactly do you need to press, and at what anglethen provide a handle for that line. In some cases this means adding a piece of wire with loops, or notches cut into an edge that will be cut away later.

Wrap the binding wire loosely into place and twist its ends together, then grip it in flat-nose pliers and give a twist, creating a Z-bend. Repeat as needed to cinch the binding wire, pulling the pieces into position for soldering. The bends allow the wire to stretch as the work swells with heat.

When using ferrous binding wire, remember to quench in water and remove the wire before pickling or the piece is likely to become acquire a thin plating of copper. If you use stainless steel binding wire it is safe to put the wrapped piece in pickle.

Clamps

Clamps can be made from various steel wires, includeing paper clips and coat hangers. These are used during soldering and gluing.

Next page