Table of Contents

THE PENGUIN PRESS

Published by the Penguin Group

Penguin Group (USA) Inc., 375 Hudson Street, New York, New York 10014, U.S.A.

Penguin Group (Canada), 90 Eglinton Avenue East, Suite 700, Toronto, Ontario

Canada M4P 2Y3 (a division of Pearson Canada Inc.) Penguin Books Ltd, 80 Strand,

London WC2R 0RL, England Penguin Ireland, 25 St Stephens Green, Dublin 2, Ireland

(a division of Penguin Books Ltd) Penguin Books Australia Ltd, 250 Camberwell Road,

Camberwell, Victoria 3124, Australia (a division of Pearson Australia Group Pty Ltd)

Penguin Books India Pvt Ltd, 11 Community Centre, Panchsheel Park,

New Delhi-110 017, India Penguin Group (NZ), 67 Apollo Drive, Rosedale,

North Shore 0632, New Zealand (a division of Pearson New Zealand Ltd)

Penguin Books (South Africa) (Pty) Ltd, 24 Sturdee Avenue,

Rosebank, Johannesburg 2196, South Africa

Penguin Books Ltd, Registered Offices:

80 Strand, London WC2R 0RL, England

First published in 2009 by The Penguin Press,

a member of Penguin Group (USA) Inc.

Copyright Matthew B. Crawford, 2009

All rights reserved

Line drawings by Thomas van Auken

Library of Congress Cataloging-in-Publication Data

Crawford, Matthew B.

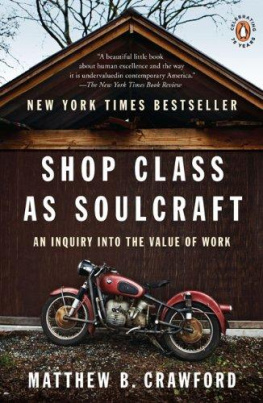

Shop class as soulcraft : an inquiry into the value of work / by Matthew B. Crawford.

p. cm.

Includes bibliographical references.

eISBN : 978-1-101-05729-2

1. Work. I. Title.

HD4824.C72 2009

331dc22

Without limiting the rights under copyright reserved above, no part of this publication may be reproduced, stored in or introduced into a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photocopying, recording, or otherwise), without the prior written permission of both the copyright owner and the above publisher of this book.

The scanning, uploading, and distribution of this book via the Internet or via any other means without the permission of the publisher is illegal and punishable by law. Please purchase only authorized electronic editions and do not participate in or encourage electronic piracy of copyrightable materials. Your support of the authors rights is appreciated.

http://us.penguingroup.com

For my girls,

the whole happy troupe

B, G & J

And in loving memory of my father,

Frank S. Crawford, Jr.

Introduction

Ayone looking for a good used machine tool should talk to Noel Dempsey, a dealer in Richmond, Virginia. Noels bustling warehouse is full of metal lathes, milling machines, and table saws, and it turns out that much of it once resided in schools. EBay is awash in such equipment, also from schools. Most of this stuff has been kicking around the secondhand market for about fifteen years; it was in the 1990s that shop class started to become a thing of the past, as educators prepared students to become knowledge workers.

The disappearance of tools from our common education is the first step toward a wider ignorance of the world of artifacts we inhabit. And, in fact, an engineering culture has developed in recent years in which the object is to hide the works, rendering many of the devices we depend on every day unintelligible to direct inspection. Lift the hood on some cars now (especially German ones), and the engine appears a bit like the shimmering, featureless obelisk that so enthralled the proto-humans in the opening scene of the movie 2001: A Space Odyssey . Essentially, there is another hood under the hood. This creeping concealedness takes various forms. The fasteners holding small appliances together now often require esoteric screwdrivers not commonly available, apparently to prevent the curious or the angry from interrogating the innards. By way of contrast, older readers will recall that until recent decades, Sears catalogues included blown-up parts diagrams and conceptual schematics for all appliances and many other mechanical goods. It was simply taken for granted that such information would be demanded by the consumer.

A decline in tool use would seem to betoken a shift in our relationship to our own stuff: more passive and more dependent. And indeed, there are fewer occasions for the kind of spiritedness that is called forth when we take things in hand for ourselves, whether to fix them or to make them. What ordinary people once made, they buy; and what they once fixed for themselves, they replace entirely or hire an expert to repair, whose expert fix often involves replacing an entire system because some minute component has failed.

In this book I would like to speak up for an ideal that is timeless but finds little accommodation today: manual competence, and the stance it entails toward the built, material world. Neither as workers nor as consumers are we much called upon to exercise such competence, most of us anyway, and merely to recommend its cultivation is to risk the scorn of those who take themselves to be the most hardheaded: the hardheaded economist will point out the opportunity costs of spending ones time making what can be bought, and the hardheaded educator will say that it is irresponsible to educate the young for the trades, which are somehow identified as jobs of the past. But we might pause to consider just how hardheaded these presumptions are, and whether they dont, on the contrary, issue from a peculiar sort of idealism, one that insistently steers young people toward the most ghostly kinds of work.

Around 1985, articles began to appear in education journals with such titles as The Soaring Technology Revolution and Preparing Kids for High-Tech and the Global Future. Of course, there is nothing new about American futurism. What is new is the wedding of futurism to what might be called virtualism: a vision of the future in which we somehow take leave of material reality and glide about in a pure information economy. New and yet not so newfor fifty years now weve been assured that we are headed for a postindustrial society. While manufacturing jobs have certainly left our shores to a disturbing degree, the manual trades have not. If you need a deck built, or your car fixed, the Chinese are of no help. Because they are in China. And in fact there are chronic labor shortages in both construction and auto repair. Yet the trades and manufacturing have long been lumped together in the mind of the pundit class as blue collar, and their requiem is intoned. More recently, this consensus has begun to show signs of cracking; in 2006 the Wall Street Journal wondered whether skilled [manual] labor is becoming one of the few sure paths to a good living.

This book is concerned less with economics than it is with the experience of making things and fixing things. I also want to consider what is at stake when such experiences recede from our common life. How does this affect the prospects for full human flourishing? Does the use of tools answer to some permanent requirement of our nature? Arguing for a renewed cultivation of manual competence puts me at odds with certain nostrums surrounding work and consumption, so this book is in part a cultural polemic. I mean to clarify the origins of, and thereby interrogate, those assumptions that lull us into accepting as inevitable, or even desirable, our increasing manual disengagement.

I will be making frequent reference to my own work experience, most recently as a motorcycle mechanic. Seeing a motorcycle about to leave my shop under its own power, several days after arriving in the back of a pickup truck, I suddenly dont feel tired, even though Ive been standing on a concrete floor all day. Through the portal of his helmet, I think I can make out the edges of a grin on the face of a guy who hasnt ridden his bike in a while. I give him a wave. With one of his hands on the throttle and the other on the clutch, I know he cant wave back. But I can hear his salute in the exuberant bwaaAAAAP! blum-blum of a crisp throttle, gratuitously revved. That sound pleases me, as I know it does him. Its a ventriloquist conversation in one mechanical voice, and the gist of it is Yeah!

Next page

![Chris Crawford [Chris Crawford] - Chris Crawford on Game Design](/uploads/posts/book/119438/thumbs/chris-crawford-chris-crawford-chris-crawford-on.jpg)