Fibres

to

Fabrics

Bev Ashford

AuthorHouse UK

1663 Liberty Drive

Bloomington, IN 47403 USA

www.authorhouse.co.uk

Phone: 0800.197.4150

2014 Bev Ashford. All rights reserved.

No part of this book may be reproduced, stored in a retrieval system, or transmitted by any means without the written permission of the author.

Published by AuthorHouse: 06/24/2016

ISBN: 978-1-4969-8467-8 (sc)

ISBN: 978-1-4969-8468-5 (e)

Any people depicted in stock imagery provided by Thinkstock are models, and such images are being used for illustrative purposes only.

Certain stock imagery Thinkstock.

Because of the dynamic nature of the Internet, any web addresses or links contained in this book may have changed since publication and may no longer be valid. The views expressed in this work are solely those of the author and do not necessarily reflect the views of the publisher, and the publisher hereby disclaims any responsibility for them.

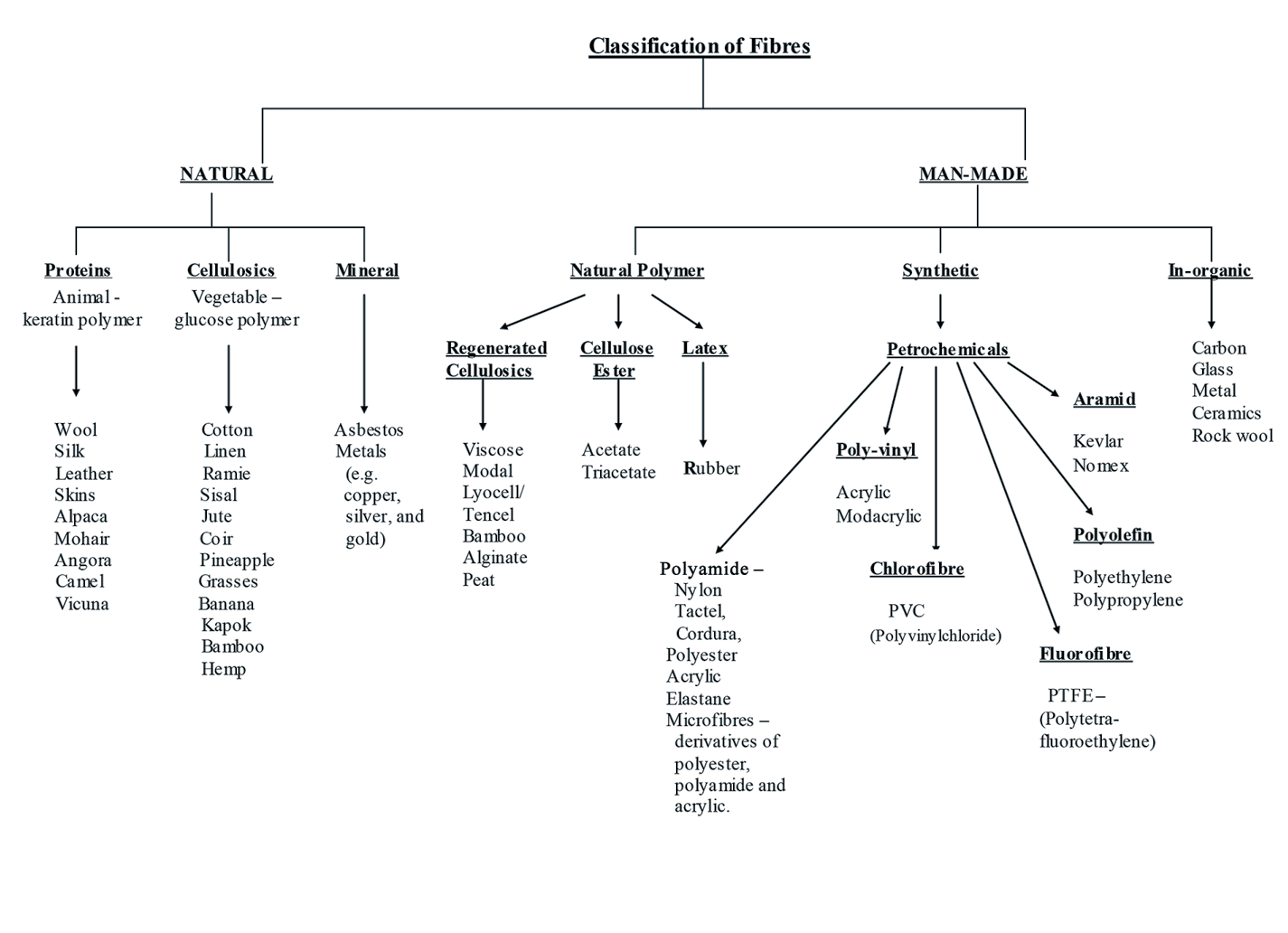

Contents

Polypropylene

Polyethylene

Polymer

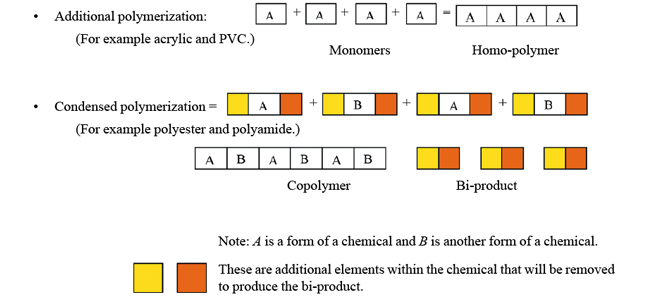

This compound is a combination of large molecules made from a chain of smaller, repeating chemical units called monomers.

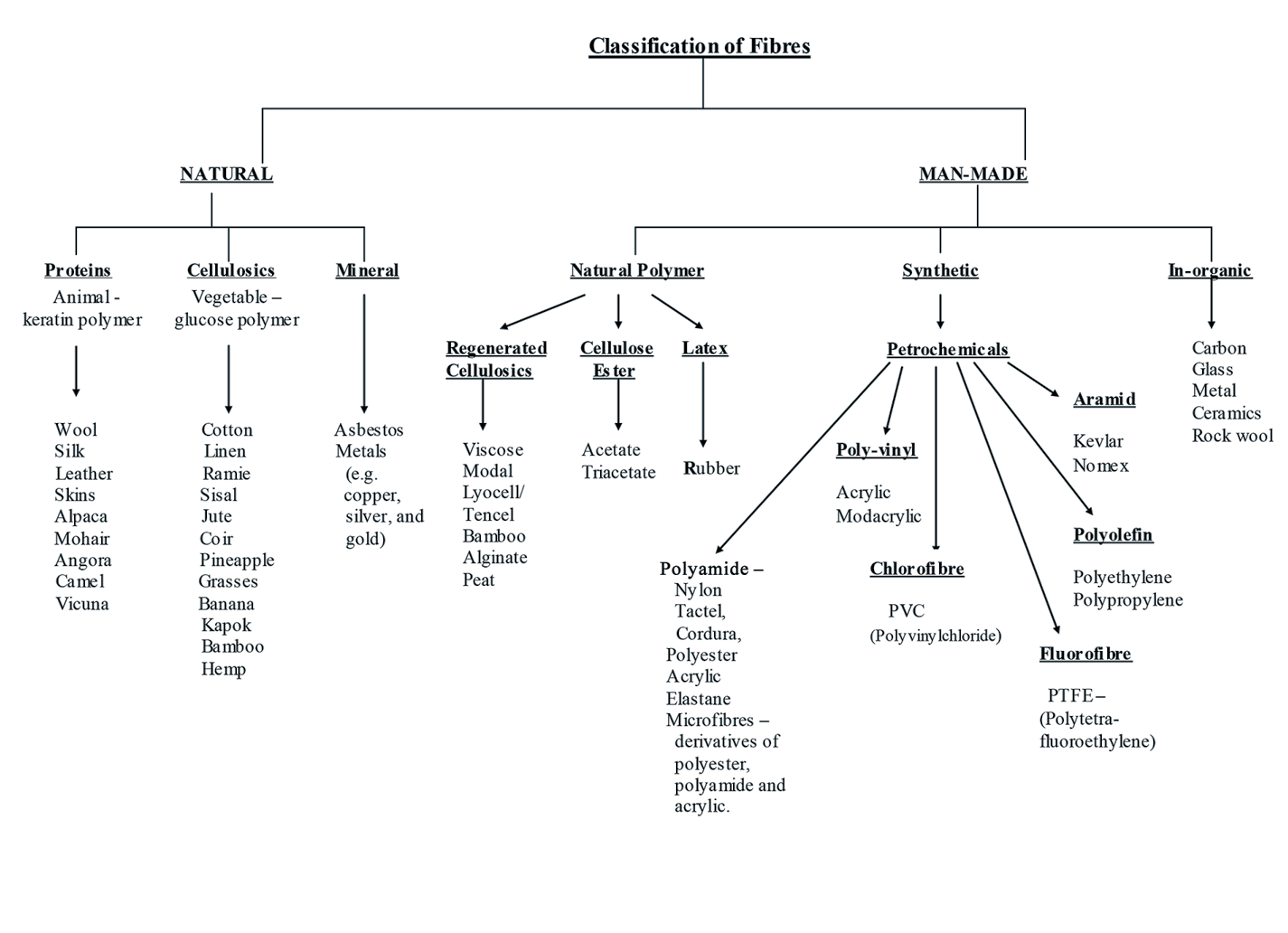

Natural Polymers

These polymers are mainly short-length fibres.

Synthetic Polymers

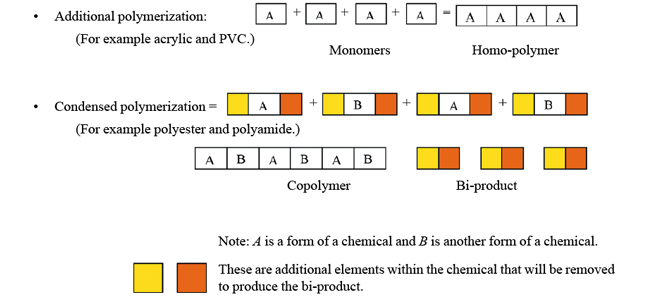

These polymers are produced by a process called polymerization to make a long chain of linear polymers. Polymerization involves combining chemicals that are held together during the process in the following ways:

Polymers belong to one of three groups:

These polymers stretch and return to their previous shapes (e.g. Lycra).

These polymers are hard and have cross links. They will not soften when heated. Therefore, they are not related to textiles but are related to resistant materials.

These polymers consist of long chains that are not cross linked and can be softened and reset (e.g. polyester, polyamides, acetates and acrylics).

Chapte r

Natura l Fibres

Animal : wool, silk, alpaca, angora, camel, cashmere, horsehair, mohair and vicuna.

Biofibre: spider silk.

Vegetable : cotton, linen, hemp, jute, bamboo, nettle, ramie, banana, pia, sisal, kapok and coir.

Mineral : asbestos.

There are over two hundred breeds of sheep, and over forty of those breeds are used within the textile industry. Of those breeds, there are over two hundred grades, and those grades are categorized into four groups:

Merino produced by merino sheep and is the best quality wool. The variety originated in Spain, but it is now also produced in Australia, America, New Zealand and Africa.

Class these are traditionally the British wools but now it is produced throughout the world. Breeds of sheep such as Bampton, Blackface, Dorset, Kent, Southdown and Welsh Mountain are utilized. The staple length varies from 520 cm with a large number of scales per centimetre and good crimp.

Class originated in the United Kingdom. It has a staple fibre length of 1045 cm but is coarser with fewer scales per centimetre and less crimp. Breeds such as Leicester, Cotswold, Cheviot and Shetland are available.

Class these are often from half-breed sheep with fibres 240 cm long, which are coarse, hair-like, very few scales per centimetre and little crimp and therefore smooth and lustrous. These are often less desirable because it has little resilience and strength, and therefore used for carpeting, rugs and low-grade cloth.

Fleeces are classified by their age, amount of weathering of the animals and whether they are taken from live or dead animals. All of these elements can affect the quality of the fibre.

Lambs wool is taken from a lamb 68 weeks old. It is fine and soft but not very strong.

Hogget wool is taken from sheep 1214 months old and is their first shearing. The fibres are fine, soft, strong, resilient and tapered. They are often used for warp yarns.

Wether wool is taken after the first shearing (usually after fourteen months) and is often dirty.

Pulled wool is taken from sheep that are slaughtered for meat. The wool is pulled from the pelt, which makes it inferior because the roots have been damaged by chemicals and extraction. Also, sheep reared for meat production often do not have good fleeces.

Dead wool is taken from a sheep that has died (not slaughtered) on the farm. The fibre has not recently been sustained with nutrients which cause the fibre to lose some resilience. It is used mainly on low-grade cloth.

Cotty wool is taken from sheep exposed to severe weather conditions or sheep lacking nourishment. It is matted (felted) and brittle which makes it a poor grade.

Taglocks is produced from torn, ragged or discoloured fleece. Usually, it is sold separately for low-grade cloth.

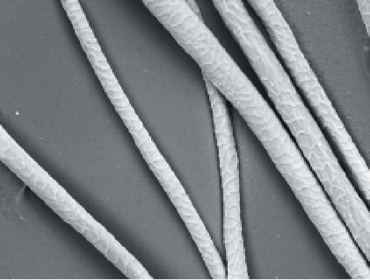

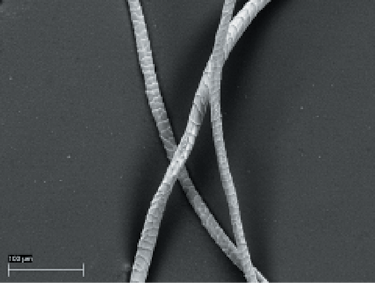

Microscopic Views

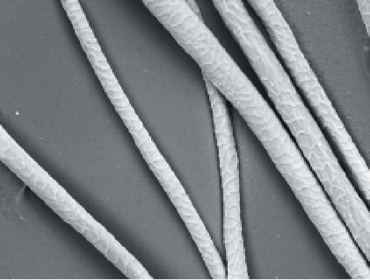

Longitudinal View of Wool

Carl Zeiss Microscopy

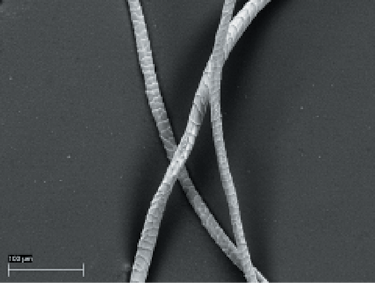

Longitudinal View of Merino

The outer scales overlap and cover many spindle-shaped cells. This structure allows movement backwards and forward, which provides the fibre with elasticity and resilience. The outer scales trap air, which provides warmth; but if the scales snag against one another felting occurs.

Labelling Wool

Logos courtesy of The Woolmark Company

Wool Mark

Products with this label must be made with 100% new wool

Wool Mark Blend

Products with this label contain a minimum of 50% new wool

Wool Blend

Products with this label contain 30 49% new wool

Properties

- Absorbency. Wool is hygroscopic; water droplets will remain on the surface due to the natural oils that are retained within the fabric. However, after a period of time, moisture will seep through. The wool can absorb about 20% of its weight in water, but it will not feel damp. Although it is absorbent, it will not allow wicking. As it is highly absorbent it can be dyed easily.

- Resiliency and Elasticity . Wool has great resilience and elasticity, which means that it has excellent draping qualities, good shape retention and creases will disappear after a period of time. A fibre can be stretched by 25% times its original length without breaking which makes it less likely to tear and giving freedom of movement to the wearer. This property arises due to the ease of slippage of the scale structure and the natural crimp of the fibre.

- Strength. Wool is the weakest of the natural fibres and the durability will be determined by the grade of wool; the more durable the wool the less resilience and texture the fabric will have. Wool can be strengthened by using a tight twist in the spinning process or plied yarns.

Next page