It has been an absolute pleasure engaging with the many specialists, engineers, suppliers, contractors and other collaborators who have helped evolve our understanding of CLTs potential by generously sharing their time, knowledge and invaluable experience (and answering my many questions). These include all those from the UK, Europe and beyond who have provided insight into the many inspiring case studies and information included. Theres insufficient space to credit each fully in turn but readers should understand that there is a wealth of experience available to help better consider and deliver CLT buildings. Each of these projects has been supported by a diverse team, with their own expertise.

The chapter author contributors are innovators and leaders in their fields and I would have liked to provide more space for them to share their experience. Do look them up, as they may be able to help support your ambitions.

I would also like to thank the project teams, both external and internal, as well as clients and collaborators, who have helped Allford Hall Monaghan Morris (AHMM) to deliver some great CLT buildings, as well as those who continue to explore better ways of building (there are plenty more brilliant buildings on the drawing board). Such work is one of the great joys of being part of such a future-facing practice.

Colleagues from across AHMM have supported the evolution and production of this book, from the outset to completion. Particular thanks are due to Rosie Ashbourne for ensuring that the images came together, as well as making a few.

Many photographers have generously allowed the use of their insightful and beautiful images, in particular Rob Parrish. Do seek out their credits, which are included at the back of this book.

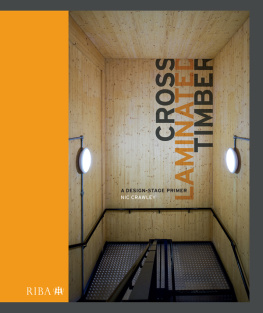

The editing and production staff at RIBA Publishing and their supporting team have provided guidance and encouragement throughout.

This book is dedicated to my mother, and to her mother, both of whom understood the vital need for better thinking and doing.

APPENDIX:

CLT PANEL CHARACTERISTICS

Key statistics (for European Spruce panels ):

| Moisture content: | 12% +/ 2% |

| Density: | 480 kg/m 3 |

| Example panel weight: | 3,100kg (for medium thickness, 160mm thick, 3.0m x 13.5m) |

| Adhesive content | c. 0.6% by volume |

| Shrinkage rates: | Dimensionally stable under normal conditions |

| Longitudinal: | 0.010% per % change in moisture |

| Perpendicular: | 0.025% per % change in moisture |

| Thermal conductivity/ resistance (): | 0.12W/mK(to EN ISO 10456) |

| Specific thermal capacity (c) | 1600J/kgK |

| Thermal mass: | Marginal |

| Airtightness | Airtight if three layers minimum |

| Fire performance (to EN 13501): | D, s2 dO |

| Char rate (calculable): | 0.670.74mm/min (depending on application) |

| Acoustic absorption coefficient: | Low. 125 Hz: 0.20.15; 500 Hz: 0.050.1; 2000 Hz: 0.1 |

| Service class (as Eurocode 5 ): | Suitable for Class 1 use (dry internal area/no increased humidity) and Class 2 (not directly exposed to moisture but higher humidity) |

| Certification, supply chain: | Timber typically PEFC and/or FSC (or local equivalent) |

| Certification, production: | Europe: CE marked when certified to BS EN 16351:2015 Timber structures. Cross laminated timber. Requirements. |

APPENDIX:

CLT PANEL SURFACE QUALITY

CLT panel surface quality: Surface quality appearance with respect to product characteristics

| Characteristics | Visible Quality (VI) | Industrial Visible Quality (IVI) | Non-Visible Quality (NVI) |

|---|

| Bonding | occasional open joints up to max. 1mm width permitted | occasional open joints up to max. 2mm width permitted | occasional open joints up to max. 3mm width permitted |