Copyright

Gulf Professional Publishing is an imprint of Elsevier

50 Hampshire Street, 5th Floor, Cambridge, MA 02139, United States

The Boulevard, Langford Lane, Kidlington, Oxford, OX5 1GB, United Kingdom

2021 Elsevier Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publishers permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

Library of Congress Cataloging-in-Publication Data

A catalog record for this book is available from the Library of Congress

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library

ISBN: 978-0-12-823796-0

For information on all Gulf Professional publications visit our website at https://www.elsevier.com/books-and-journals

Publisher: Joe Hayton

Senior Acquisitions Editor: Katie Hammon

Editorial Project Manager: Tracy I. Tufaga

Production Project Manager: Sojan P. Pazhayattil

Cover Designer: Christian Bilbow

Typeset by SPi Global, India

Acknowledgment

I would like to express my gratitude to my partner, Ms. Tamara Zhunussova for her constant support.

Chapter 1: Ball-valve applications and design

Abstract

This chapter is dedicated to ball valves as a very robust valve choice used for stopping and starting the flow. This chapter provides a relatively in-depth and detailed review of different critical metallic and soft components in this type of valve. Double isolation and bleed characteristic of the ball valves as per the API 6D standard for pipeline valves have been explained in detail. Different aspects of ball valve design such as bore, flow capacity, end connections to the piping system, torque requirement, and interlocking are included. A separate section is dedicated to material selection for different components of the ball valves such as body, bonnet, seat, stem, etc. This chapter is very well illustrated with pictures of ball valves during assembly, test, packing, and preservation. This chapter addresses different requirements of this valve more than design, such as lifting, tagging and marking, testing as well as packing and preservation.

Keywords

Ball valves; Design; Testing; Packing and preservation; Oil and gas industry

Ball-valve application examples

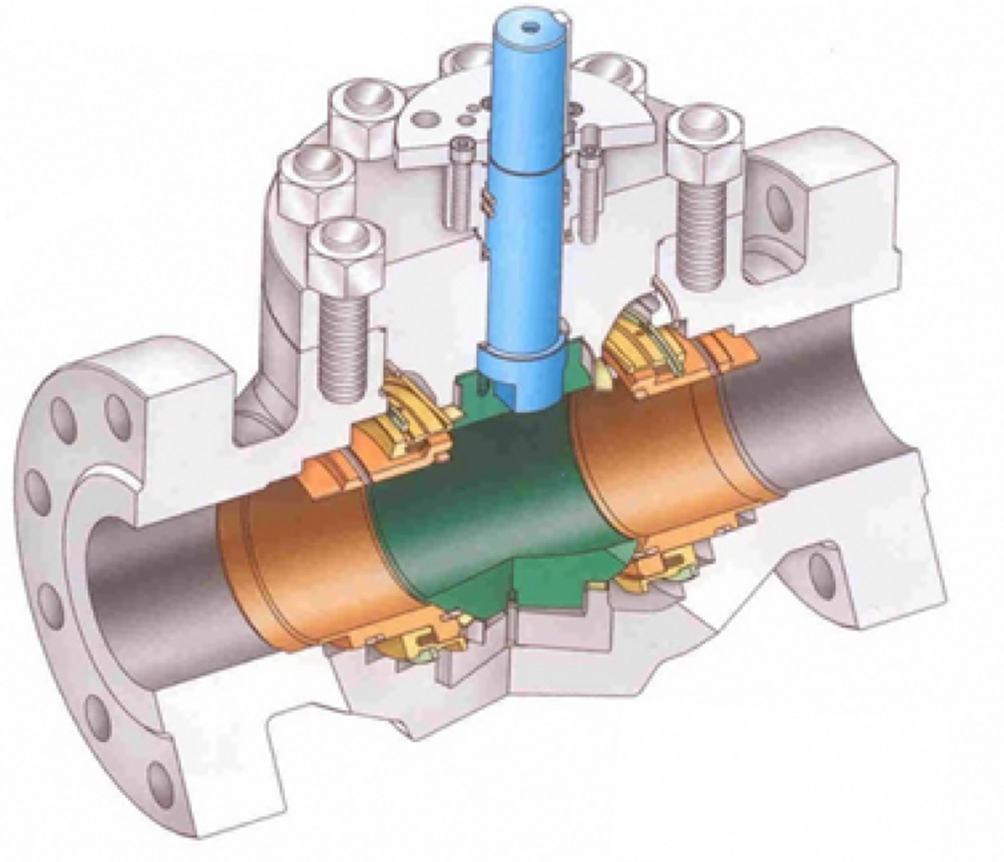

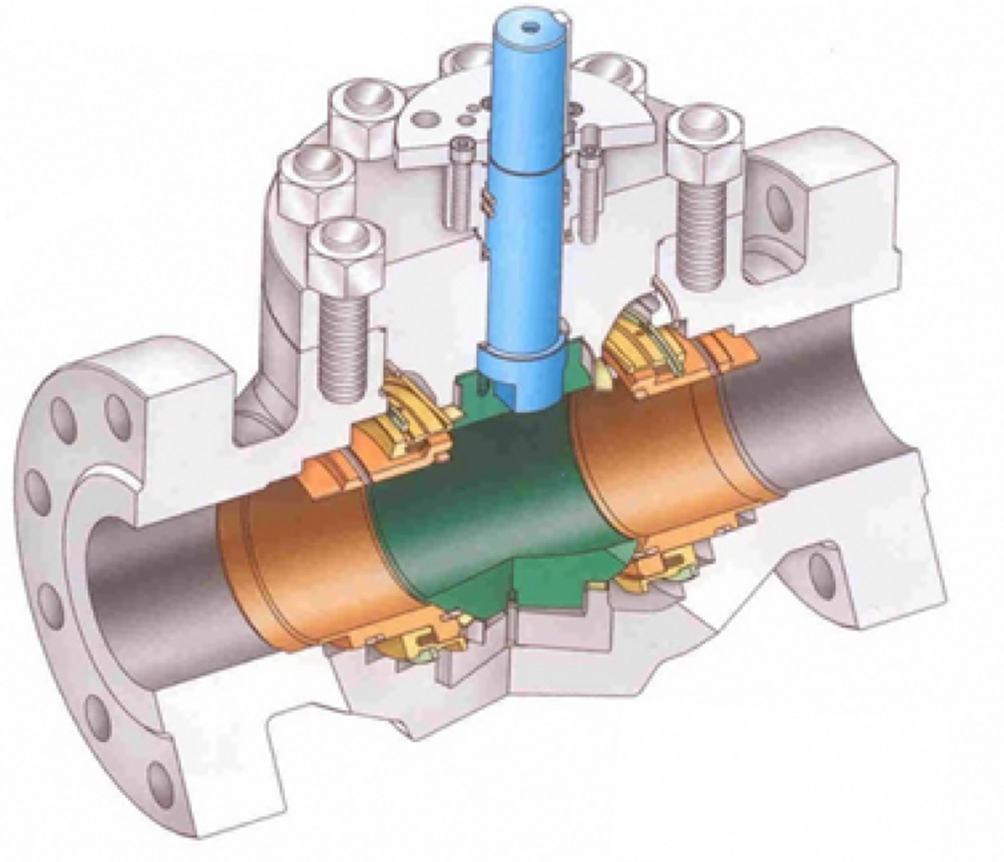

Ball valves are usually selected for process and aggressive services containing hydrocarbon oil and gas. A ball valve (see ) is used for on/off purposes and not throttling (flow control).

Fig. 1.1 Ball valve.

Injection lines that inject seawater into the reservoirs for enhanced oil recovery in high-pressure classes are mixed with hydrocarbon services. Ball valves are the best valves for on/off purposes in this type of application. Alternative choices such as butterfly and wedge gate valves are not as robust as ball valves in process services.

Ball valves for water injection lines in the offshore industry are manufactured in exotic materials such as 25 chromium super duplex, in medium to large sizes such as 12, 14, and 16, and in high-pressure classes such as class 1500. Although a butterfly valve is cheaper than a ball valve, it is not recommended for a seawater injection line since the fluid is aggressive, contains hydrocarbon, and flows at high pressure. Butterfly valves may not be robust enough for high-pressure and aggressive process services containing hydrocarbons.

Wedge-type gate valves (see ) are also not recommended for this application, for several reasons.

- Wedge gate valves that are 12 tall or taller may interfere with operator access to the handwheel.

- Actuation of wedge gate valves must be done accurately to avoid seat and wedge overtorqueing and resulting damages. Overtorqueing a wedge gate valve increases the risk of stem bending.

- Small-size ball valves that are 2, 1, or smaller, can be less expensive than wedge gate valves in the same size and pressure class due to less material usage and weight.

- Wedge gate valves can be heavier and more costly due to their taller height and yoke arrangement.

- 1 or ball valves can be used instead of wedge gate valves for vent-and-drain purposes.

- Quarter-turn ball valves can be operated faster and more easily than gate valves. These valves allow a 90-degree turn of the stem and ball, providing for full opening to full closing position, and vice versa.

Fig. 1.2 Wedge gate valve.

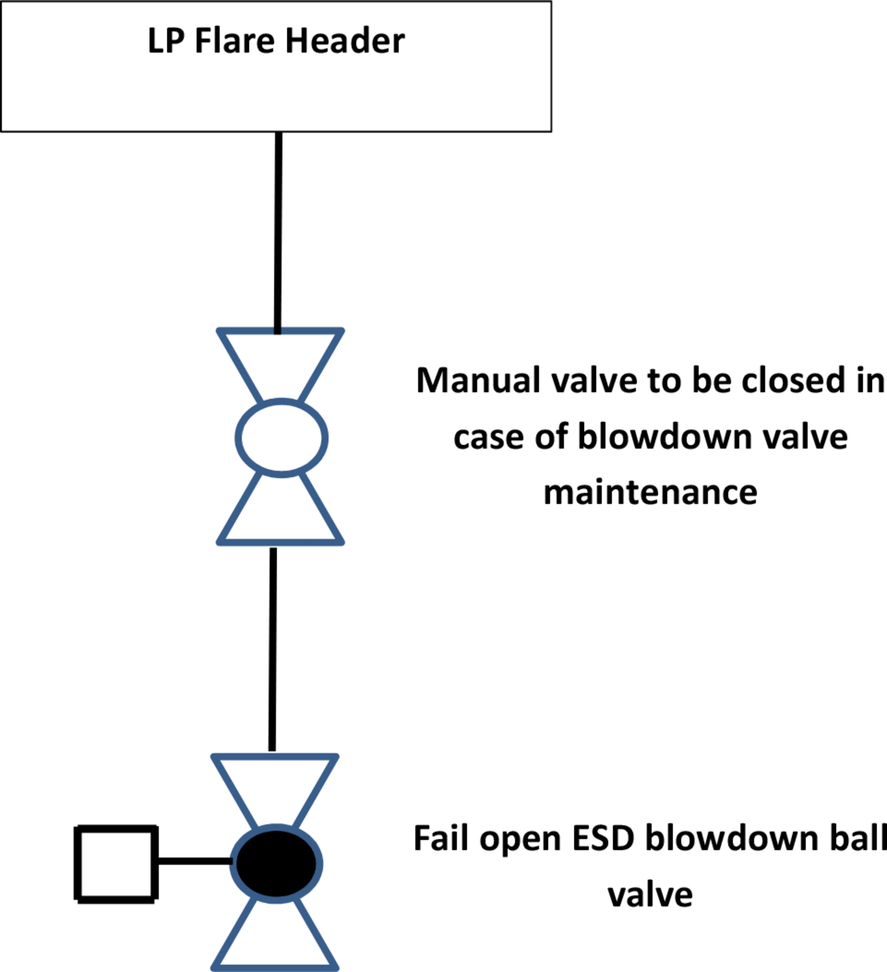

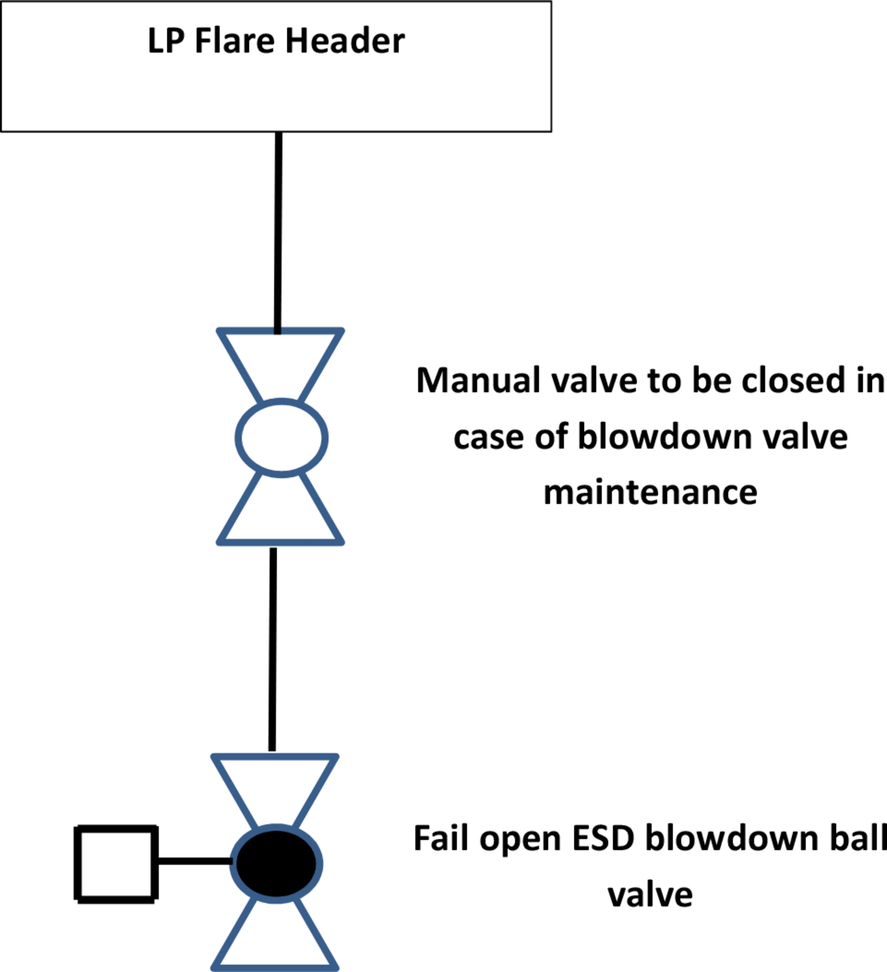

Actuated ball valves with emergency shutdown (ESD) functions are used for blowdown purposes to release overpressure piping or equipment to the flare (see ).

Fig. 1.3 Blowdown valve.

When compared to through conduit gate (TCG) valves, ball valves have the advantage of being more compact vertically. TCG valves occupy more space vertically, especially if they are actuated due to vertically mounted actuation.

Although ball valves may be more expensive than TCG valves in smaller sizes, TCG valves in larger sizes such as 30 and 38 are usually more expensive than ball valves. discusses the selection of a ball valve instead of a TCG valve for the inlet of a 24-class 1500 separator.

Ball valves are not recommended for fast-opening applications. Generally, it is possible to reduce the opening time of a fail-open actuated valve through installation of a quick exhaust valve on the control panel to release the instrument air from the pneumatic actuator in the fail mode quickly. However, ball-valve seats and disks are in contact during the opening and closing, which can jeopardize the fast opening characteristic. In addition, moving the relatively large and heavy ball requires higher stem torque, a larger actuator, and perhaps a longer opening time. A ball-valve manufacturer was asked about using a soft-seat ball valve for this application, but the manufacturer believed that the fast opening of a soft-seat ball valve in 2 s could result in damage to the soft seat because of rapid contact with the ball.