Measurement Systems and Sensors

Second Edition

For a complete listing of titles in the

Artech House Remote Sensing Library,

turn to the back of this book.

Measurement Systems and Sensors

Second Edition

Waldemar Nawrocki

Library of Congress Cataloging-in-Publication Data

A catalog record for this book is available from the U.S. Library of Congress.

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library.

Cover design by John Gomes

ISBN 13: 978-1-60807-932-2

2016 ARTECH H OUSE

685 Canton Street

Norwood, MA 02062

All rights reserved. Printed and bound in the United States of America. No part of this book may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from the publisher.

All terms mentioned in this book that are known to be trademarks or service marks have been appropriately capitalized. Artech House cannot attest to the accuracy of this information. Use of a term in this book should not be regarded as affecting the validity of any trademark or service mark.

Contents

Chapter 1

Computer-Based Measurement Systems

One of the components of measurement technology development is the development of measurement systems. By the measurement systems, we refer to a set of material and organizational resources, as well as software for information processing, aggregated in order to obtain, transmit, and process measuring data, and to display and store them. The measurement system is equipped with a personal computer (PC) or a microprocessor chip; its task is to control information flow in the system, to process measuring data, and sometimes to store them. The computer or the microprocessor chip is a system controller; that is a device managing the system. The measurement systems described in this book are exclusively digital systems. Measurement systems with the PC, called computer-based measurement systems, are of great importance. Considering the widespread use of PCs in both industrial and research measuring laboratories, the building of a computer measurement system usually does not imply the purchase of a separate computer, but allows the utilization of the existing ones. This is especially important and economically effective in the case of building up computer measurement systems for the realization of temporary measuring tasks. Separate classes of computer measurement systems are the simplest two-component systems, composed of one measuring instrument plus one computer as the system controller. It is self-evident that the possibility of applying an existing computer for setting up the simplest measurement system decreases construction expenses of such a system considerably.

1.1CONFIGURATION AND STRUCTURE OF MEASUREMENT SYSTEMS

An important problem in designing and operating the measurement system is the organization of information flow in the system. Two criteria are essential for this organization:

The kind of transmission in the system: serial, bit-by-bit, or parallel, where the information is transmitted in the form of multibit words. According to this criterion, there are systems with serial interfaces and parallel interfaces.

The mode of information exchange between system devices with regard to the connection configuration of instruments: linear (bus), star, or daisy chain (arranged in rows).

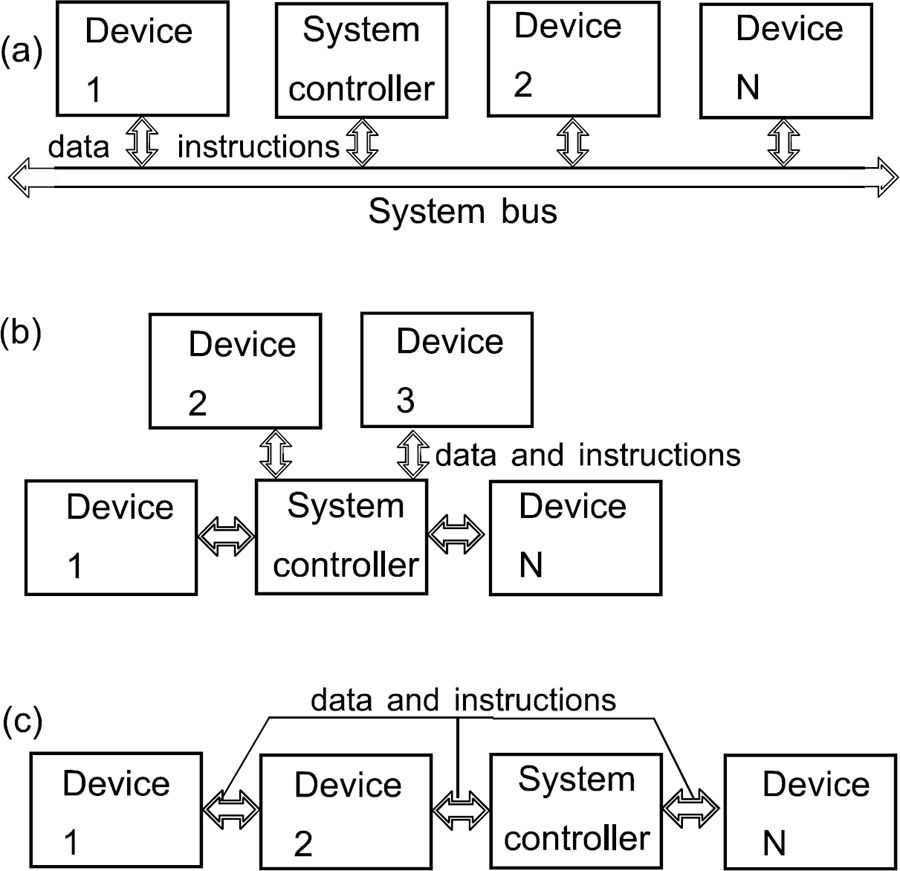

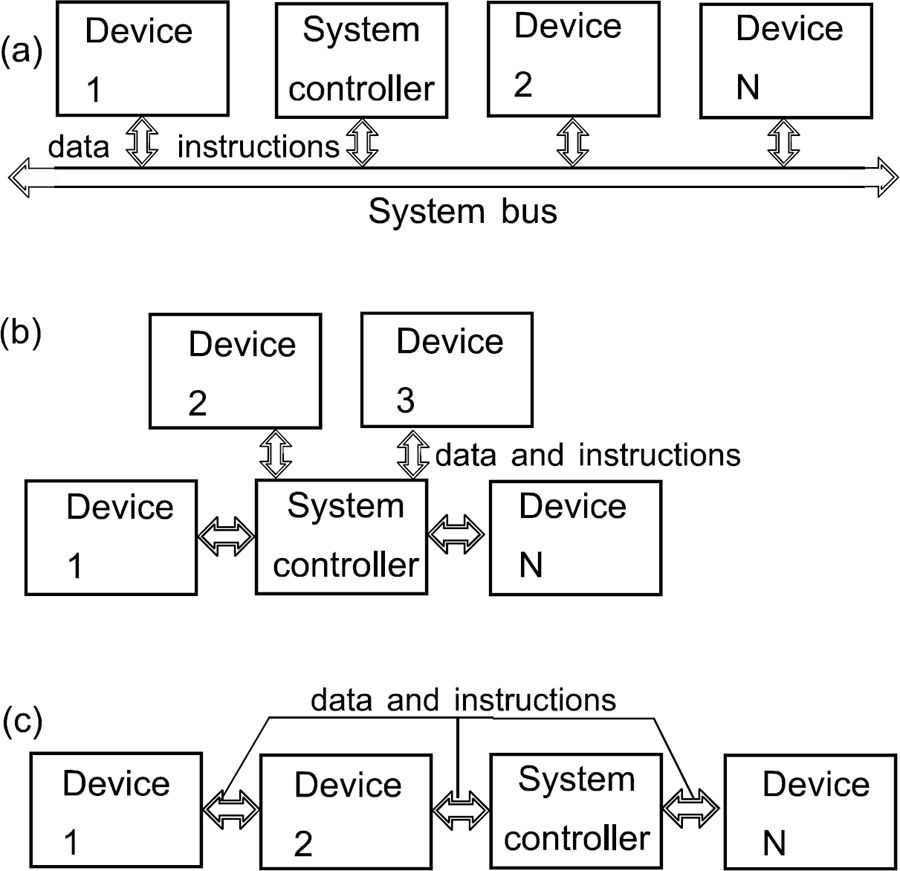

Measurement systems in the linear, star, or daisy chain configurations are shown in . The linear configuration is used most often; in this configuration, the exchange of instructions passed between system devices is realized exclusively by the data bus of the system. The linear configuration is elastic because it makes change of the system structure readily possible by adding or disconnecting devices or by changing the placement of instruments in relation to other devices.

Figure 1.1 Configuration of measurement system: (a) linear, (b) star, and (c) daisy chain.

The star configuration requires the number of multibit computer inputs equal to the number of devices in the system (except for the computer). An advantage of this configuration is the fact that it does not address the bus devices because they are connected to determined computer inputs. Alteration of the structure of such a system is difficult, and sometimes impossible, since the measurement system contains a greater number of instruments. Even less elastic is the daisy chain configuration, in which the exchange is possible only between neighboring instruments. Such configuration is sometimes used in the case of simple measurement systems with the only one way of information flow. In discussing measurement system configurations, it must be remembered that a lot of measurement systems consist of two components only: the controller and the measurement instrument. The problem of system configuration thus does not appear.

The measurement system designed for measuring various physical quantities in the object consists of the following functional components:

A sensor or a set of sensors of physical quantities. The sensor causes changes of a definite electric parameter in the function of the value of a measured quantity (e.g., the resistance alteration in the function of temperature).

Measurement transducers, in which the electric parameter of the sensor is transformed into the direct voltage or the direct current (e.g., a transducer as the Wheatstone bridge with the bridge branch as resistance sensor with the electric voltage at the bridge output).

Conditioners or circuits standardizing the level of signal from the measurement transducer to the range of the input voltage of the analog-to-digital converter (ADC).

ADCs or digital measuring instruments containing such a converter; the task of ADCs is to convert analog into digital signals.

Devices for visual display of measurement results in the form of the display field of a digital measurement instrument, the screen of a digital instrument (e.g., the digital oscilloscope or the frequency analyzer), or a computer monitor.

A computer with its software and memory resources.

Actuators or generators of test signals.

Power supplies of the object, operating autonomously or under control (optional).

The flow-process diagram in a measurement system is shown in . It is worth mentioning that the measurement system is oftenparticularly in industrypart of a control-measurement system. Measuring data is for controlling objects measured, for diagnosing the objects, and monitoring their state.

More complicated measurement systems can be constructed in the hierarchical structure. On the lowest level, there are measurement subsystems arranged to collect data from the object. Subsystems are situated on a separate area (e.g., in the manufacturing room or the laboratory). Data from such subsystems are sent to the main controller of the measurement system (see ). The main controller of the system not only receives initially processed measuring data, but it can also send commands relating to the execution of a measuring procedure or a set of commands for measurement instruments to subsystems. The main controller of the measurement system can also take advantage of memory resources, data display, and data storage devices.

Next page