Mothes - Process Design

Here you can read online Mothes - Process Design full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2017, publisher: manufective consulting, genre: Computer. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

Process Design: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Process Design" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Process Design — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Process Design" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

Process Design

Synthesis, Intensification, andIntegration of Chemical Processes

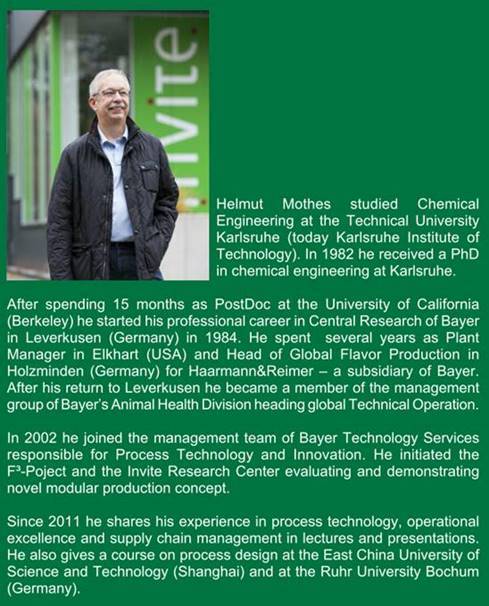

Helmut Mothes

ISBN 978-3-00-049077-4

Copyright: @ 2017 Helmut Mothes

Publisher: manufective consulting

www.manufective.com

The material in this eBook also appears inthe print version of this title: ISBN: 978-3-00-049149-8.

Foreword

In the past process design aimed atsolutions converting raw materials into products in a technically convincingand economically profitable manner. This effort has certainly createdimpressive, technical, and economic progress.

Today the world faces new challenges. Foodsupply for a growing world population, healthcare for an aging society, andglobal warming represent an on-going challenge to society. At the same time,biotechnology, nanotechnology, green technologies, and the internet of thingsoffer new opportunities.

Future process design still requires soundchemical engineering skills and system thinking capabilities, but also an openmind-set and a serious commitment for efficient, sustainable no-regret-solutionsin a complex, volatile future.

Process design can build on many excellentchemical engineering textbooks addressing unit operations. A few books coverthe area of process synthesis, intensification, and integration.

This textbook communicates basic ideasabout process design to chemical engineering students and encouragesexperienced engineers to reflect on and perhaps challenge their dailyapproach to process design.

Concepts, methodologies, and philosophiesconstitute the main topic of this book promoting a holistic process designmethodology that introduces the concept of no-regret- solutions to theclassic synthesis approach for chemical processes. These no-regret- solutionsare process designs that give the priority to design solutions offering arobust and sustainable performance in all feasible future scenarios.

The book is a summary of my coursesProcess Intensification and Process Design given at the TechnicalUniversity Dresden (TU Dresden - 2008), East China University of Science andTechnology (ECUST Shanghai 2012-2014) and Ruhr University Bochum (RUB 2014-2015).

Prof. Lange encouraged me to present a2-day lecture on process intensification at the TU Dresden. Prof. Weiling Luangave me the opportunity to give a course on process design as guest professorat the East China University of Science and Technology (ECUST) in Shanghai. InGermany, Prof. Grnewald became my hoist and partner for a lecture on processdesign at the Ruhr University Bochum (RUB).

To a large extend, my book on processdesign builds on experiences and materials from Bayer Technology Services. Thebook would not be feasible without the input of many Bayer people technicalcontributions, exciting suggestions, and enlightening discussions.

1. Introduction

The chemical industry represents a maturebusiness. During the last 150 years, the production facilities and supplychains of the chemical and pharmaceutical industry have developed into complex,global systems. Processes in the chemical industry have reached a sophisticatedtechnological level.

In the past, the chemical industries couldrely on steadily growing economies creating a stable and predictable frameworkfor product demand, raw material availability, and technological progress. Thisframework provided a reliable and sound basis to design chemical processes,plants and whole supply chains.

Today an intensive, global competitioncharacterizes the chemical business. Shorter product cycles, unreliable rawmaterial supplies, and disruptive technology development increase the risk thata process design optimal for a fixed set of operational parameters cannotflexibly respond to product demand fluctuations or changing raw materials inthe future. Ecological necessities aggravate the requirements for sustainableprocess designs.

The conventional process designmethodology is particularly suited for precisely defined design problems withstraightforward solutions. A design problem of the past could rely onpredictable boundary conditions. This framework concerning resourceavailability and product demand combined with new sustainability goals adduncertainty to process design. Global production systems form a huge,multi-dimensional solution space for a process design task.

Complexity andUncertainty evolve into key aspects of future process design.

New design methodologies require featuresto reduce complexity and manage uncertainty from idea generation throughprocess development and plant implementation.

Of course, a sound knowledge of chemicalengineering remains essential for process design. In the future, a processmethodology has not only to provide sound design algorithms for unit operationsand equipment, but also to efficiently handle uncertainty and complexity. Adesign methodology must lead to process designs that react flexibly towardsunexpected changes of the business environment.

This book discusses a holistic processdesign methodology dealing with uncertainty and complexity. The discussion onsmart methodologies focuses on key design features and applies them towardsselected design problems.

2. Process Design A conceptual Approach

The ultimate task of a process designmethodology is to create the blueprint of a chemical process converting rawmaterials into products. This blueprint is used in later design stages toengineer the process in detail and finally to construct a plant.

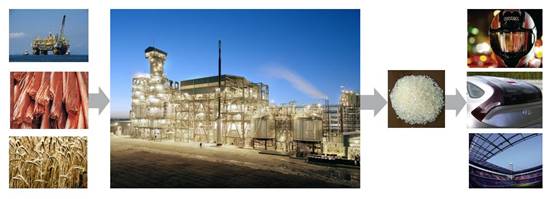

illustratesthis task. A chemical process converts raw materials into an intermediateproduct such as plastic granules used to produce the consumer goods fromhelmets to car parts and stadium roofs.

Figure 1 :Process Design Task (Source: Bayer)

The design methodology should lead toefficient and sustainable process designs. Efficient processes convert rawmaterials into products with a minimum of material and energy input.Sustainable processes do not waste valuable resources and hurt the environment.Yield, productivity or other engineering driven parameters primarilycharacterize the efficiency of a chemical process design. Ultimately, thesescientific parameters are translated into economic parameters particularlyprofitability.

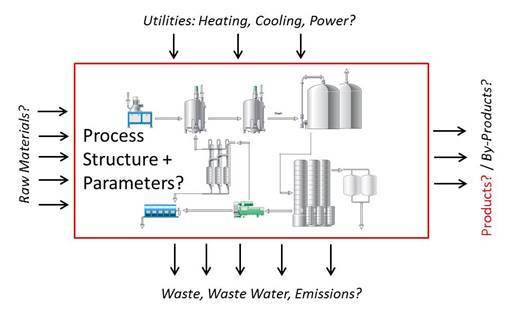

Normally the product quantity and qualityprovide the input information. Process design defines the process structure andparameters to achieve the production goal ().

During the past 50 years, manymethodologies have been proposed and used to design chemical processes.Generally, design methodologies are tailored towards a specific task: grassroot design, retrofitting, or optimization. Before a holistic designmethodology is illustrated, some general aspects of process design arediscussed to provide some beneficial insights into process design.

Figure 2 :Input-Output Scheme for Process Design

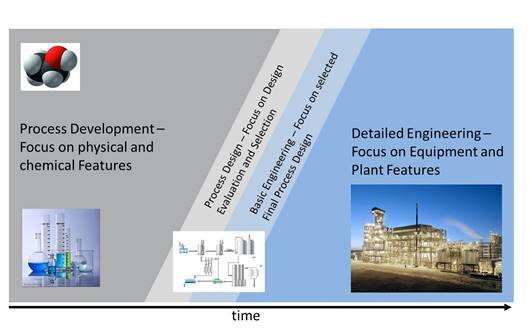

Process design is part of a large effort toconvert a process idea into a functioning chemical plant including processdevelopment, process design, basic engineering, detailed engineering, and plantconstruction.

gives aschematic description of the overall process leading to a new plant. Processdevelopment provides the input for process design. Process design translatesthis information into a process structure. This process structure often remainsunchanged during later project phases.

Font size:

Interval:

Bookmark:

Similar books «Process Design»

Look at similar books to Process Design. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Process Design and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.