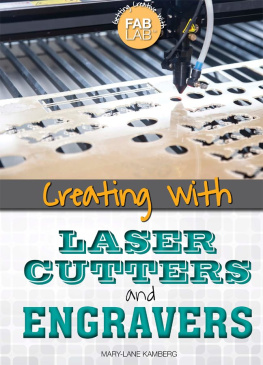

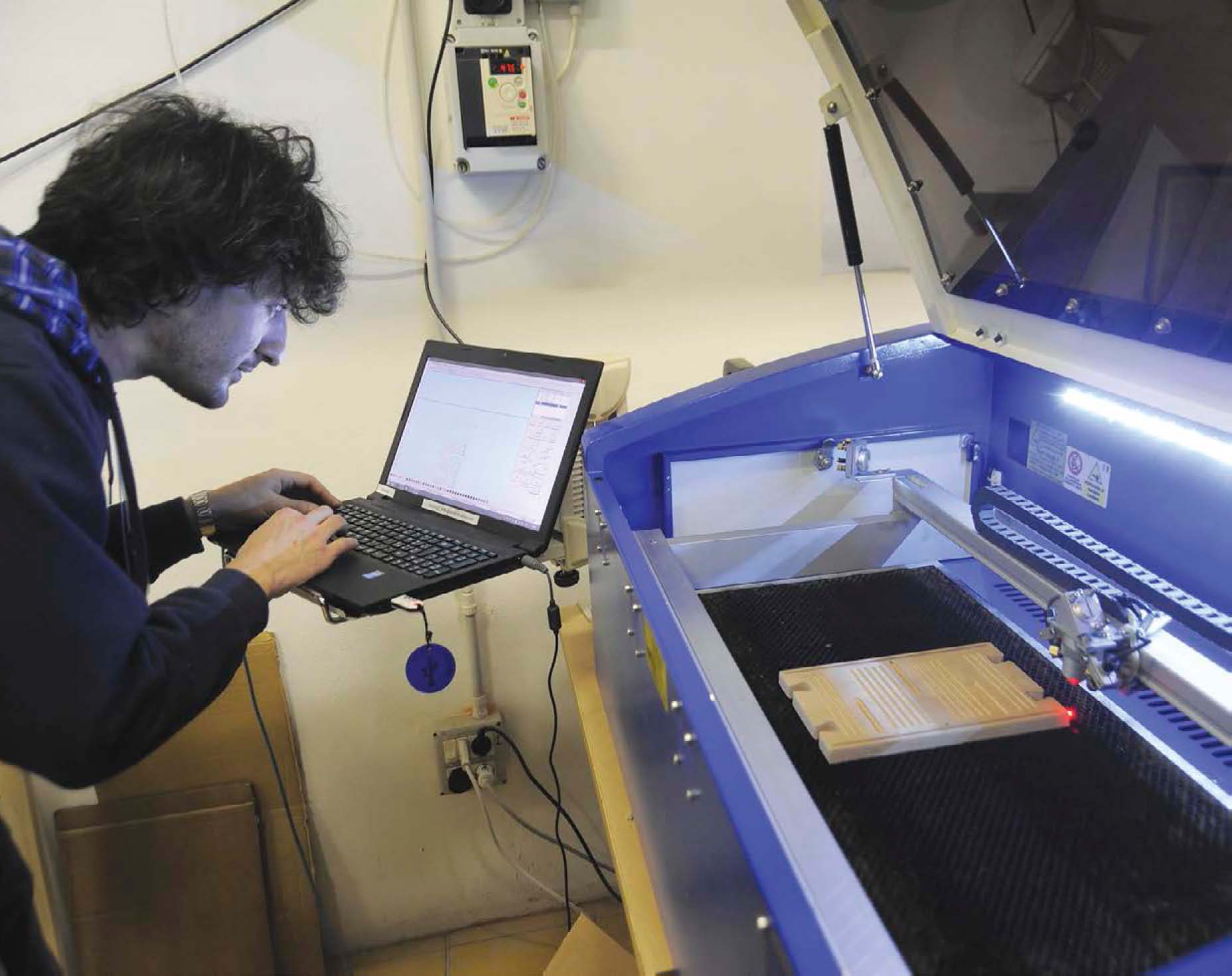

You can use a laser cutter for both two-dimensional and threedimensional items such as this cube designed and fabricated at the Vinn:Lab at the technical college in Wildau, Germany.

Whats your budget? Material costs vary widely. You can buy a 6-inch by 24-inch (15-cm by 61-cm) sheet of one-quarterinch- (0.63-cm-) thick basswood for around $10 at art, craft, and hobby retailers. A 12-inch by 12-inch (30.5-cm by 30.5-cm) piece of one-eighth-inch- (0.32-cm-) thick ABS plastic costs about the same. A ready-made bamboo tissue box runs about $20. A set of natural Brazilian agate slices with 18K gold trim will cost a lot more. A well-sized mahogany serving tray might go for more than $350. If you choose a relatively expensive material, consider making a prototype out of a cheaper material first. A prototype is an original model of an item used as a sample that can be copied or adjusted to create future designs.

Keep in mind that creating a prototype in a Fab Lab is perfectly fine. However, if you plan to produce many copies of the item, you will be crossing into a gray area of a Fab Labs purpose. If youre making jewelry for friends, youre probably OK. But if youre trying to make lots of items to sell to raise money for college, buy a car, or even to donate to a charitable cause, youre engaging in production. Fab Labs are designed as educational environments, not personal factories. If you want to pursue a profitable business, think about investing in your own laser cutter.

Several manufacturers offer new desktop laser cutters for sale between about $1,500 and $5,000. You can find laser cutters for sale directly from manufacturers. Before you buy, do some research and talk with your Fab Lab technician for advice about which features are most important to you. You can find used machines as well, but buyer beware. Be sure to check out the laser cutter before you pay for it.

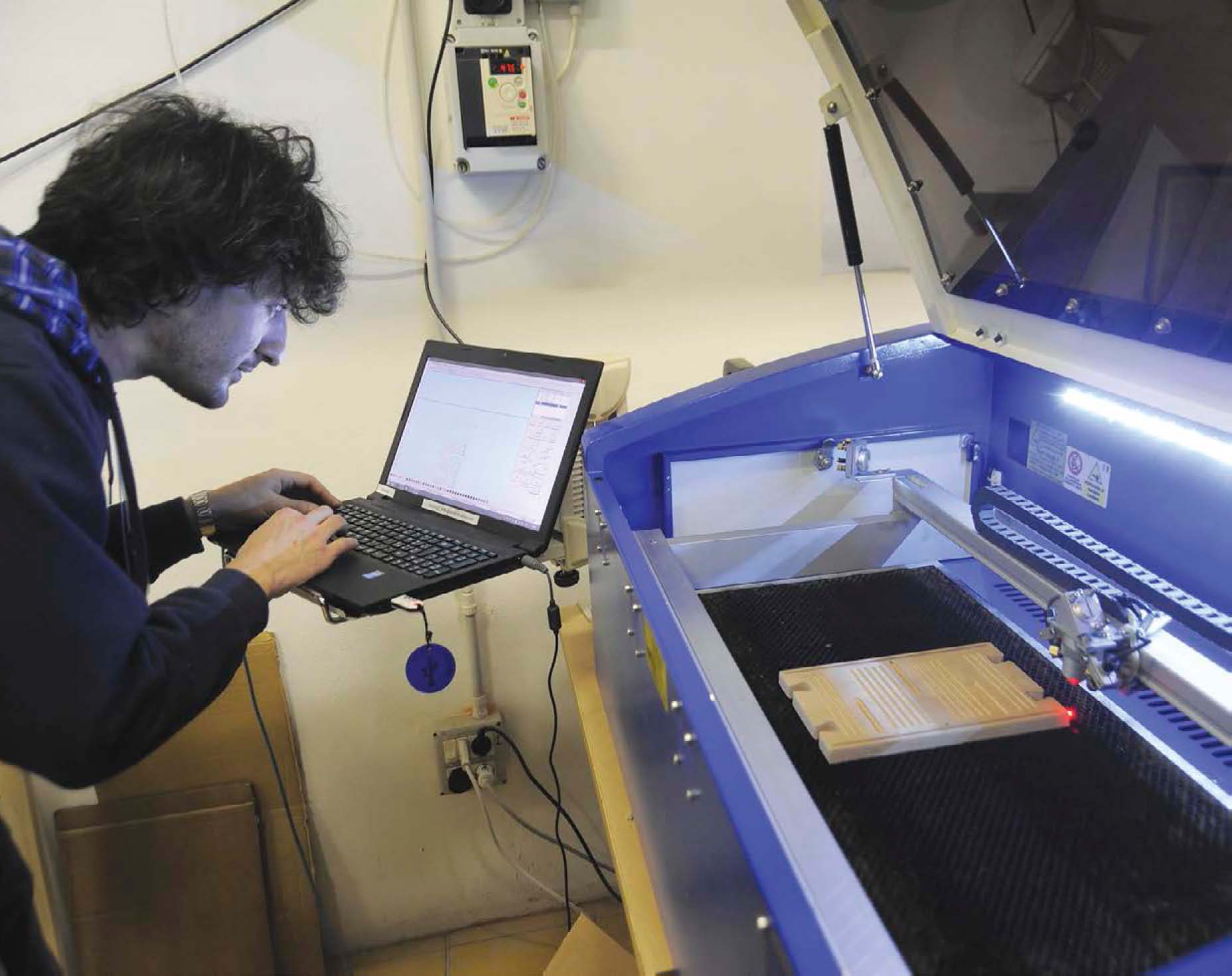

Using a laser cutter involves computer skills combined with knowledge of machinery operation. You can learn these skills in a Fab Lab. You dont need to know them before your first visit.

Tips for Successful Projects

Here are some tips from experienced laser cutters to help make your own project successful:

To avoid smoke stains on engraved edges, especially on wood or leather, use masking tape to protect the surface. (You may need to increase the power a little as a result.) Peel off the tape when the engraving is complete.

The grain in natural wood comes from the tree rings. The rings come from different growing patterns over a season or year. Darker grain is harder than light grain. Therefore, when you engrave natural wood, youll see a striped pattern in the finished design. If you want a more uniform look, use laser plywood instead of natural wood.

If your finished product needs to be painted, then plan to paint before you cut. That will keep grooves free of paint that might creep into the groove if you wait to paint until after engraving.

If youre engraving a material with a thin wood veneer on top, be sure to engrave deep enough that the laser burns all the way through the veneer. If not, youll end up with an uneven mixture of the veneer and whatever is below it.

Cutting multiple parts of the same shape is easier if you can butt them up against each other. If you draw two squares using four lines for each square, the laser will see (and make) two cuts on the shared line, risking a burn. Instead, make the first square with four lines, but the second square with only threeshare the fourth line with the first square.

If you want to engrave a design that has mostly lines, you can use the raster setting, but using the vector setting will be much faster. Adjust to use lower power and higher speed than in raster mode.

For extra sharpness when engraving, you can create a thin line around the edges of the cut. This is a nice effect for letters and words or other shapes. Make your image in a vector file and set the laser for vector cut. Use low power and fast speed to keep the laser from cutting all the way through the edge. The resulting thin line highlights the image.

Make more of the same thing all at the same time. Suppose you want to make dozens of bookmarks engraved with the same image. Instead of making them one at a time, lay out a bunch of them at once. The laser can engrave them all in one cut. Make a vector file the size of the laser bed, and copy and paste as many items as you can fit into that space.

Try not to be too disappointed if your first laser cutting projects turn out less than perfect. Keep trying. Experiment with different materials and different power, speed, and frequency settings. When you get an outcome youre happy with, record the materials and settings you used for future reference. As you gain expertise, you can try more complex designs for even better results.