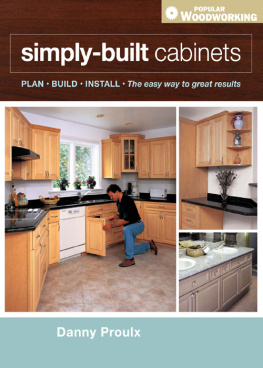

simply-built cabinets

Danny Proulx

READ THIS IMPORTANT SAFETY NOTICE

To prevent accidents, keep safety in mind while you work. Use the safety guards installed on power equipment; they are for your protection.

When working on power equipment, keep fingers away from saw blades, wear safety goggles to prevent injuries from flying wood chips and sawdust, wear hearing protection and consider installing a dust vacuum to reduce the amount of airborne sawdust in your woodshop.

Dont wear loose clothing, such as neckties or shirts with loose sleeves, or jewelry, such as rings, necklaces or bracelets, when working on power equipment. Tie back long hair to prevent it from getting caught in your equipment.

People who are sensitive to certain chemicals should check the chemical content of any product before using it.

Due to the variability of local conditions, construction materials, skill levels, etc., neither the author nor Popular Woodworking Books assumes any responsibility for any accidents, injuries, damages or other losses incurred resulting from the material presented in this book.

The authors and editors who compiled this book have tried to make the contents as accurate and correct as possible. Plans, illustrations, photographs and text have been carefully checked. All instructions, plans and projects should be carefully read, studied and understood before beginning construction.

Prices listed for supplies and equipment were current at the time of publication and are subject to change.

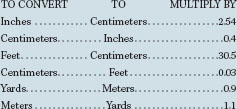

METRIC CONVERSION CHART

SIMPLY-BUILT CABINETS. Copyright 2011 by Danny Proulx. Printed and bound in China. All rights reserved. No part of this book may be reproduced in any form or by any electronic or mechanical means including information storage and retrieval systems without permission in writing from the publisher, except by a reviewer, who may quote brief passages in a review. Published by Popular Woodworking Books, an imprint of F+W Media, Inc., 4700 East Galbraith Road, Cincinnati, Ohio, 45236. (800) 289-0963 First edition.

Distributed in Canada by Fraser Direct

100 Armstrong Avenue

Georgetown, Ontario L7G 5S4

Canada

Distributed in the U.K. and Europe by F&W Media International, LTD

Brunel House, Forde Close

Newton Abbot

TQ12 4PU

UK

Tel: (+44) 1626 323200

Fax: (+44) 1626 323319

E-mail:

Distributed in Australia by Capricorn Link

P.O. Box 704

Windsor, NSW 2756 Australia

Visit our Web site at www.popularwoodworking.com.

Other fine Popular Woodworking Books are available from your local bookstore or direct from the publisher.

Other fine Popular Woodworking Books are available from your local bookstore or direct from the publisher.

15 14 13 12 11 5 4 3 2 1

ACQUISITIONS EDITOR: David Thiel

DESIGNER: Brian Roeth

PRODUCTION COORDINATOR: Mark Griffin

PHOTOGRAPHERS: Danny Proulx, Michael Bowie, LUX Photographic Services, Inc.

ILLUSTRATOR: Len Churchill

ABOUT THE AUTHOR

For over 15 years, Danny shared with us his passion for woodworking through his books, magazine articles and website advice, as well as through teaching and mentoring his students and clients. He founded Rideau Cabinet in 1989 and started building kitchens and specialty cabinets. Over time, Danny married his love of woodworking and writing with his photographic skills and wrote 15 books during a period of 9 years. He also wrote for several magazines including Canadian Woodworking and CabinetMaker Magazine. He started giving seminars in his home for new woodworkers and eventually started teaching courses at Algonquin College in Ottawa, Ontario.

Preface

Danny Proulx was a multi-faceted individual who knew how to build cabinets and furniture and could write clearly and concisely, while at the same time sounding like he was right there in your shop giving you instructions.

Much of Dannys business was dedicated to building cabinetry, and he was very good at his business. Keeping it simple is what this book is all about. The projects in Simply-Built Cabinets can be made using basic power woodworking tools: a pocket-hole drilling jig, a biscuit joiner, a table saw and a drill press. Plus, some hand tools: a chisel, cordless screwdriver, hammer, etc.

Several of the projects are built in sections that are then assembled to create the final piece. This can serve several purposes. Its easier to transport several small parts than one big one and, if you have a small woodworking shop like most of us do, you will appreciate having to build only one or two pieces of a project at one time. When these are finished, then can be moved to create more room in your shop so you can continue building.

The materials for these furniture projects can be found at most home centers. Danny designed his projects so the materials can simply be cut to size and assembled. You dont need a planer or jointer to prepare the hardwood parts. The sheets goods can be cut to size using several different tools. A table saw is best, but a straightedge used with a circular saw will get the job done too. And, if all you have is a jig saw, well, that will work also.

Danny preferred tools with cords and batteries, because they are efficient and he could get more work done in a shorter amount of time. If you are able to only work weekends on your woodworking projects, power tools are your best friendsyour work will progress quickly and efficiently.

Simply-Built Cabinets will give you the information and insight to build cabientry for multiple rooms in your home, all in a simple and understandable manner. Thats what Danny did best.

introduction

Cabinetmaking, like many other skills, requires nothing more than attention to detail and patience. This skill is learned and improved upon with practice and, I believe, is well within the scope of most home woodworkers.

The cabinetmaking style detailed in this book is a simple, straightforward style used by many cabinet manufacturers, with some minor variations. Common dimensions such as cabinet depth, height and width, are detailed, as well as simple rules to calculate door widths. As you will see in later chapters, the normal depth for a base cabinet is 24, upper cabinets (when used in conjunction with base cabinets) are approximately 12 deep, and the space between the upper and lower cabinets is from 16 to 18.

This building style was adapted from many sources. Primarily, its a blend of the best features of Europeanand North Americanstyle cabinetry. The carcass, or cabinet, is built with  or melamine-coated particleboard (PB) or veneered sheet materials. I have offered information on both the face frame and European frameless cabinet design. Adjustable legs are offered as an option, installed on the base cabinets, to maximize the cutting from a sheet of PB and to allow for easy installation.

or melamine-coated particleboard (PB) or veneered sheet materials. I have offered information on both the face frame and European frameless cabinet design. Adjustable legs are offered as an option, installed on the base cabinets, to maximize the cutting from a sheet of PB and to allow for easy installation.

Other fine Popular Woodworking Books are available from your local bookstore or direct from the publisher.

Other fine Popular Woodworking Books are available from your local bookstore or direct from the publisher.

or melamine-coated particleboard (PB) or veneered sheet materials. I have offered information on both the face frame and European frameless cabinet design. Adjustable legs are offered as an option, installed on the base cabinets, to maximize the cutting from a sheet of PB and to allow for easy installation.

or melamine-coated particleboard (PB) or veneered sheet materials. I have offered information on both the face frame and European frameless cabinet design. Adjustable legs are offered as an option, installed on the base cabinets, to maximize the cutting from a sheet of PB and to allow for easy installation.