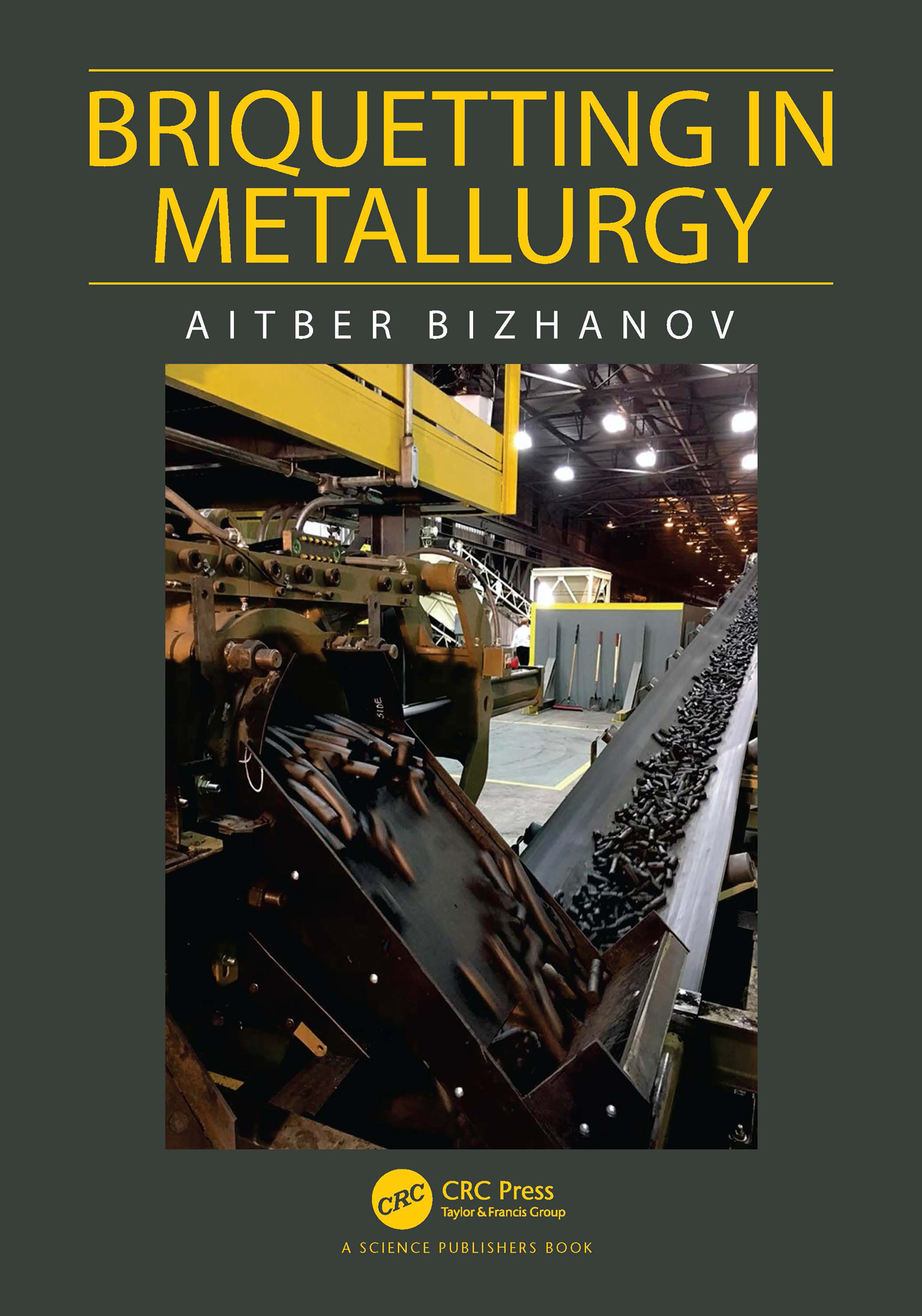

Briquetting in Metallurgy

Aitber Bizhanov

J.C. Steele & Sons Representative in Russia&CIS

Cover image provided by the author, Aitber Bizhanov

First edition published 2022

by CRC Press

6000 Broken Sound Parkway NW, Suite 300, Boca Raton, FL 33487-2742

and by CRC Press

4 Park Square, Milton Park, Abingdon, Oxon, OX14 4RN

CRC Press is an imprint of Taylor & Francis Group, LLC

2022 Taylor & Francis Group, LLC

Reasonable efforts have been made to publish reliable data and information, but the author and publisher cannot assume responsibility for the validity of all materials or the consequences of their use. The authors and publishers have attempted to trace the copyright holders of all material reproduced in this publication and apologize to copyright holders if permission to publish in this form has not been obtained. If any copyright material has not been acknowledged please write and let us know so we may rectify in any future reprint.

Except as permitted under U.S. Copyright Law, no part of this book may be reprinted, reproduced, transmitted, or utilized in any form by any electronic, mechanical, or other means, now known or hereafter invented, including photocopying, microfilming, and recording, or in any information storage or retrieval system, without written permission from the publishers.

For permission to photocopy or use material electronically from this work, access

Trademark notice: Product or corporate names may be trademarks or registered trademarks and are used only for identification and explanation without intent to infringe.

Library of Congress Cataloging-in-Publication Data (applied for)

ISBN: 978-0-367-46230-7 (hbk)

ISBN: 978-1-032-34101-9 (pbk)

ISBN: 978-1-003-02764-5 (ebk)

DOI: 10.1201/9781003027645

Typeset in Times New Roman

by Radiant Productions

Preface

What time are we now living in? People tend to define different stages of life and eras in history. The modern era is also defined as the era of information technology, the era of artificial intelligence and digitalization. It is difficult to disagree with the fact that new information technologies play a significant role in the life of a modern person, but one should not forget that metallurgy has long been and remains the locomotive of scientific and technological progress since the role that steel plays in the life of modern society is incomparable with any other building and construction material. Therefore, in a sense, humanity is still living in the Iron Age.

Metallurgy, especially ferrous metallurgy, will undoubtedly play a dominant role in industry in the foreseeable future. Along with this, it is metallurgy that is one of the main sources of harmful emissions into the atmosphere. The fact is that in the process of metallurgical production, a significant amount of fine-grained materials (dust and sludge) with a large content of iron and other important components is formed. Their direct reuse in metallurgical furnaces and reactors is impossible without preliminary agglomeration. And such agglomerationthe formation of a dense mass from finely dispersed raw materials during its high-temperature processingis accompanied by emissions of substances extremely hazardous to human health.

How can one fail to recall the famous myth about Prometheus, who stole fire from Hephaestus, the patron saint of metallurgy, and gave it to people, for which, as you know, he was severely punished by the Gods. The acquisition of fire, of course, changed a persons life in the literal and figurative sense, but, in particular, it turned into many problems. Punishment, according to Greek mythology, came to people in the form of Pandora with her ill-fated box. Similarly, pyrometallurgy is one of the main sources of harmful emissions into the atmosphere that pose a serious threat to the very life of mankind. In the structure of these emissions, a significant share (up to 50%) are emissions from sinter plants. Therefore, the efforts of scientists and metallurgists to find ways of so-called cold agglomeration of raw materials for iron smelting do not stop.

This book is the result of more than ten years of research by the author aimed at finding an effective method for briquetting in ferrous metallurgy. Acquaintance with briquette took place when I was the commercial director of one of the largest Russian producers of commercial pig iron and ferromanganese. Located almost within the city limits, the enterprise did not have any reserves of territory and the possibility of building a sinter plant, which, together with the accumulated large volumes of anthropogenic materials, made the choice of briquetting uncontested. I am still grateful to the owners of the metallurgical plant for the support of my initiatives and the unique experience I have gained in briquetting. I will note, by the way, which, as often happens, the first pancake, as they say in Russia, came out lumpy.

Next page