Lawrence K. Wang , Nazih K. Shammas and Yung-Tse Hung (eds.) Handbook of Environmental Engineering Biosolids Engineering and Management 10.1007/978-1-59745-481-0_1 Humana Press, a part of Springer Science+Business Media, LLC 2008

1. Transport and Pumping of Sewage Sludge and Biosolids

Nazih K. Shammas 1, 2 and Lawrence K. Wang 1, 2, 3

(1)

Lenox Institute of Water Technology, Lenox, MA

(2)

Krofta Engineering Corporation, Lenox, MA

(3)

Zorex Corporation, Newtonville, NY

Abstract

The fundamental objective of all wastewater treatment operations is to remove undesirable constituents present in wastewater and consolidate these materials for further processing and disposal. Solids removed by wastewater treatment processes include screenings and grit, naturally floating materials called scum, and the removed solids from primary and secondary clarifiers called sewage sludge. This chapter dis cusses the transportation of solids or the movement of sewage sludge, treated sludge (biosolids), scum, or other miscellaneous solids from point to point for treatment, stor age, or disposal. Transportation includes movement of solids by pumping and pipelines, conveyors, or hauling equipment.

Key Words

Sewage sludgec biosolids transport pumping pipelines headloss conveyors hauling trucks trains barges risk to exposure

Introduction

1.1 Sewage Sludge and Biosolids

Solids removed by wastewater treatment processes include screenings and grit, nat urally floating materials called scum, and the removed solids from primary and sec ondary clarifiers called sewage sludge. The term biosolids . is the new name for what had previously been referred to as stabilized sewage sludge. Biosolids are primarily organic treated wastewater residues from municipal wastewater treatment plantswith the emphasis on the word treated that are suitable for recycling as a soil amendment. Sewage sludge . is now the term used to refer to untreated primary and secondary organic solids. This usage of terminology differentiates between biosolids, which refer to the organic solids that have received stabilization treatment at a municipal wastewater treatment plant, and the many other types of sludges (such as industrial oil and gas field wastes) that cannot be beneficially recycled as soil amendment.

1.2 Biosolids Applications

Biosolids can be used as a slow release nitrogen fertilizer with low concentrations of other plant nutrients. In addition to significant amounts of nitrogen, biosolids also contain phosphorus, potassium, and essential micronutrients such as zinc and iron. Many soils in the western United States are deficient in micronutrients. Biosolids are rich in organic matter that can improve soil quality by improving water-holding capacity, soil structure, and air and water transport. Proper use of biosolids can ultimately decrease topsoil erosion.

Moreover, biosolids may provide an economic benefit in addition to their environ mental advantages. Continuous application of three dry tons per acre every other year to dry land planted with wheat may produce comparable yields, higher protein content, and larger economic returns compared with the use of 50 to 60 pounds per acre of commercial nitrogen fertilizer.

1.3 Transport and Pumping of Sewage Sludge and Biosolids

The fundamental objective of all wastewater treatment operations is to remove unde sirable constituents present in wastewater and consolidate these materials for further processing, utilization, or disposal. This chapter discusses the transportation of solids removed by the wastewater treatment processes or the movement of scum, sewage sludge, biosolids, or other miscellaneous solids from point to point for treatment, storage, utilization, or disposal. Transportation includes movement of solids by pumping and pipelines, conveyors, or hauling equipment.

Pumping

Biosolids pumps have many uses in a municipal wastewater treatment plant. Settled primary sludge must be moved regularly; activated sludge must be returned continuously to aeration tanks, with the extra biosolids wasted; scum must be pumped to digestion tanks; and biosolids must be recirculated and transferred within the plant in processes such as digestion, trickling filter operation, and final disposal. The type of pumping station used at the plant depends on the characteristics of the sludge itself.

Unless biosolids have been dewatered, they can be transported most efficiently and economically by pumping through pipelines. Biosolids are subject to the same physical laws as other fluids. Simply stated, work put into a fluid by a pump alters velocity, elevation, and pressure, and overcomes friction loss. The unique flow characteristics of biosolids create special problems and constraints. Nevertheless, biosolids have been successfully pumped through short pipelines at up to 20% solids by weight, as well as in pipelines of over 10 miles (16 km) long at up to 8% solids concentrations ().

2.1 Types of Sludge and Biosolids Pumps

Wastewater sludge and biosolids can range in consistency from a watery scum to thick paste-like slurry. A different type of pump may be required for each type of solids. Pumps that are currently utilized for sludge and biosolids transport include centrifugal, torque flow, plunger, piston, piston/hydraulic diaphragm, progressive cavity, rotary, diaphragm, ejector, and air lift types. Water eductor pumps are sometimes used to pump grit from aerated grit removal tanks.

2.1.1 Centrifugal Pumps

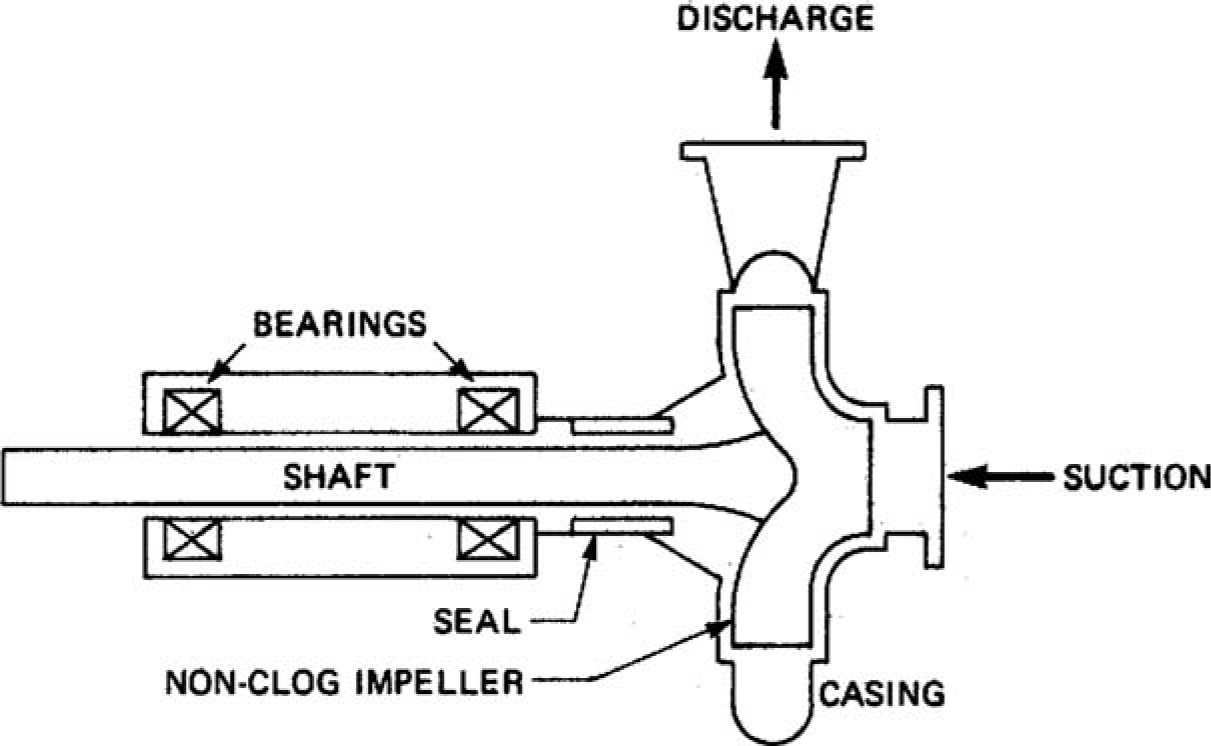

A centrifugal pump (Figure ) consists of a set of rotating vanes in a housing or casing. The vanes may be either open or enclosed. The vanes impart energy to a fluid through centrifugal force. The nonclog centrifugal pump for wastewater or biosolids, in comparison to a centrifugal pump designed to handle clean water, has fewer but larger and less obstructed vane passageways in the impeller; has greater clearances between impeller and casing; and has sturdier bearings, shafts, and seals. Such nonclog centrifugal pumps may be used to circulate digester contents and transfer sludges with lower solids concentrations, such as waste activated sludge. The larger passageways and greater clearances result in increased reliability at a cost of lower efficiency.

Fig. 1.1.

Centrifugal pump. Source : US EPA ().

The basic problem with using any form of centrifugal pump on sludge/biosolids is choosing the correct size. At any given speed, centrifugal pumps operate well only if the pumping head is within a relatively narrow range; the variable nature of sludge/biosolids, however, causes pumping heads to vary. The selected pumps must be large enough to pass solids without clogging of the impellers and yet small enough to avoid the problem of diluting the sludge/biosolids by drawing in large quantities of overlying wastewater. Throttling the discharge to reduce the capacity of a centrifugal pump is impractical both because of energy inefficiency and because frequent clogging of the throttling valve will occur. It is recommended that centrifugal pumps requiring capacity adjustment be equipped with variable-speed drives. Fixed capacity in multiple pump applications is achieved by equipping each pump with a discharge flow meter and using the flow meter signal in conjunction with the variable speed drive to control the speed of the pump. Seals last longer if back suction pumps are used. Utilizing the back of the impeller for suction removes areas of high pressure inside the pump casing from the location of the seal and prolongs seal life.