3D PRINTER

USER GUIDE

A Complete Step By Step User Manual For Understanding The Fundamentals Of 3D Printing, How To Maintain And Troubleshoot Common Difficulties

Keith J. Prout

Copyright 2020 Keith J. Prout

All right reserved

Kindly note that this book cannot be reproduced in any way or by any means without obtaining written consent from the author or his representative

Table Of Contents

Introduction

Although it has not been larger than the internet as it was once projected to be, 3D printing has slowly and progressively started to change how manufacturing is done: from the tedious subtractive way of fabrication to a more easier additive manufacturing.

3D printing involves a host of different technological processes that ensure the manufacturing of a range of three-dimensional objects by adding layers upon layers of different build materials. This technology, which has long been enjoyed by early adopters, has been applied in many industries that would be discussed extensively later

Other topical issues, talked about in this book, relating to 3D printing you might want to know are:

What 3D printing truly is

The brief and key history of 3D printing

How 3D printing works and the seven distinctive processes of 3D printing categorized by the American Society for Testing and Materials (ASTM)

How to choose a 3D printer

The tools and build materials useful of a good additive manufacturing

This guide also shed some light on the benefits and applications of 3D printing which can only be achieved when a quality print is made. The guide elaborated on how a quality print could be achieved through appropriate slicer settings and proper machine maintenance.

By the time you are done with this book, you would have been able to fully understand what 3D printing is, the difference between traditional and additive manufacturing, what to look out for when buying a 3D printer, what software, how to slice your 3D digital model, and how to maintain your personal 3D printer. You would also be vast in the use of some 3D printing terms.

Chapter 1: Basics Of 3D Printing

What Is 3D Printing?

3D printing, also known as additive manufacturing, is the process of 'printing' or manufacturing three-dimensional objects using 3D printers by stacking up layer-by-layer 3D printing materials.

The manufacturing objects' processes using 3D printers could be more than one, but the methods are the same. The layer, designed with Computer-Aided-Design (CAD) software, is printed in a 3D printer.

The term additive manufacturing for 3D printing comes from the method by which objects are 3D printed. Unlike the traditional subtractive manufacturing method, 3D printers produce three-dimensional objects by adding layer upon layer of production materials.

As earlier stated, this is directly opposite to how objects are made traditionally. The traditional manufacturing process involves subtracting part of a larger block of material for production. Cutting or carving out objects from the material they are made of is the hallmark of traditional manufacturing. For example, woods are cut out of a log of woods to make wooden shapes

But with 3D printing, complex objects are made only by adding layers of materials upon layers to meet the objects' 3D digital models. More 3D beneficial differences to traditional manufacturing would be discussed later.

Key History

Printing in 3D format has been in existence for quite a long time; it all started in 1981 after Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute filed a patent (JP S56-144478) was published. In 1v980, Kodama invented an additive rapid-prototyping system to produce a model using photopolymers. They were, at the time, called Rapid Prototyping (RP) plan because they were thought to be fast and cost-effective.

Before Hideo Kodama's invention, the idea of 3D printing and its additive manufacturing method was first described by Raymond F. Jones in a 1950 issue of Astounding Science Fiction magazine. He termed the process as 'molecular spray.'

Five years later, in 1986, after Kodama's invention, the first 3D patent was issued to Charles "Chuck" Hull of the 3D Systems Corporation. His patent was filed in 1984 for a stereolithography fabrication system, also known as the stereolithography apparatus (SLA). Hull's stereolithography 3D system uses digital data of a 3D model to create real three-dimensional objects. His patent is considered the first because Kodama did not follow through with his patent request after one year of filing it.

Hull's 3D Systems Corporation went ahead to produce the first commercial 3D printer, the SLA-1, in 1987. The SLA-1 was not sold until 1988, after it had gone through rigorous testing.

Although SLA could be regarded as the first 3D printing technology produced in 1987, another technology, known as the Selective Laser Sintering, was also designed that year. In 1987, Carl Deckard, a student of the University of Texas and working at the university, filed a patent for the SLS RP printing process. Hull's 3D Systems Corporation later acquired the 3D printing process after the SLS patent was issued in 1989.

As research and development continued in the production of RP systems in finding a more suitable manufacturing process, Scott Crump, who co-founded Stratasys Inc., developed the technology widely employed by 3D printers today, the Fusion Deposition Modeling (FDM), in 1988. He filed for a patent for this process in 1989 and sold the first FDM printer in 1992 through Stratasys.

With the entrance of different technologies and makers in the years following the developments of SLA, SLS and FDM printers, the application of 3D printing grew beyond industrial prototyping. Hence, the materials used also grew beyond plastic. Metals and human cell materials were successfully introduced. In 2006, a 3D printer maker, Objet, introduced a 3D printer that could use different types of raw materials to 3D print any objects.

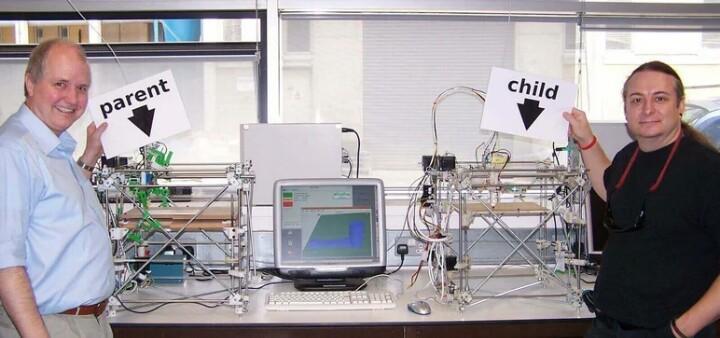

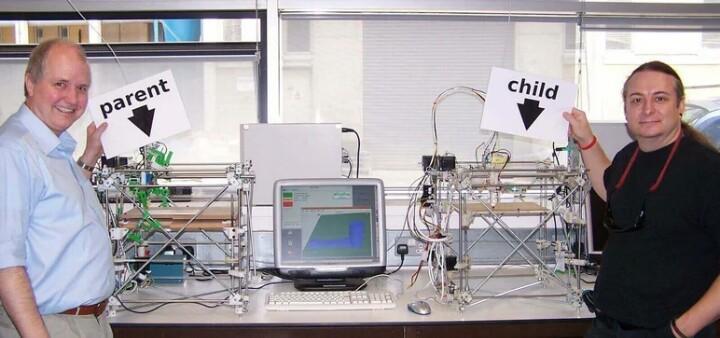

3D printers became affordable at the entrance of an open-source self-replicating printer in 2005. Dr. Adrian Bowyer of Bath University started the RepRap Project to initiate a low-cost 3D printer development. RepRap is an acronym for Replicating Rapid 'prototype.' This remained until 2008 when the RepRap makers produced Darwin, the dream of an absolute self-replicating 3DP (3D Printer) into fruition.

All of the plastic parts for the 3D printer with Vik Olliver on the right were produced by the machine with Dr. Adrian Bowyer of RepRap on the left.

In 2009, a RepRap open-source investor, MakerBot, started selling 'Do-It-Yourself' (DIY) kits that would allow buyers to assemble or make their desktop 3D printers. MakerBot was later, in 2013, acquired by the initiator of the FDM printing process, Stratasys. The years following this saw a sharp rise in this tech's adoption, as the world's first 3D printed plane flew the skies above the University of Southampton.

In 2012, two alternative 3D printing processes were introduced into the RP market. By June that year, B9Creator introduced its printer using Digital Light Processing (DLP). The DLP project was funded through the site Kickstarter.

Although 3D printing has not entirely taken over the world's manufacturing process, it was initially thought of by some that it has gone beyond the initial use for rapid prototyping to direct digital manufacturing (DDM) for high-end industrial manufacturing or desktop manufacturing for low-end manufacturing for hobbyists.