Page List

PREFACE

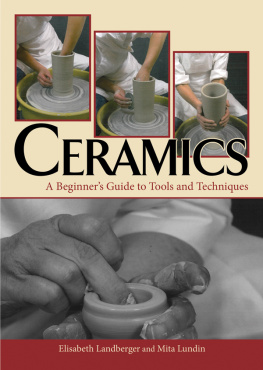

T his book has been written from my point of view as a ceramicist with a working knowledge of ceramic kiln-firings. The style and format is based on my practice, which includes the production of a porcelain design range including tableware, lighting and vessels, as well as teaching wheel throwing. Importantly for this book I also ran a kiln-firing service in East London for around twelve years until 2019. My ceramics degree at Bath School of Art and Design and my Masters in Ceramics & Glass at the Royal College of Art have heavily informed the information in this book but the content is also based on countless conversations with fellow professionals over the years who I owe a great deal and are too many to name. The book includes some Maker Profiles from ceramicists whose work I consider interesting and who illustrate the use of kilns to create unique and beautiful work. Their profiles concentrate on ways that they use their kiln to create their work, including unusual approaches that break some of the normal rules, which are written about in this book. This is because, whilst this book aims to give a structure to work from, it is by no means a doctrine and I would encourage rule-breaking to push innovation forward, create new work and make new discoveries.

Throughout my time offering a kiln-firing service I often came into contact with my customers misunderstandings, particularly those who were only just starting out, around kilns and their function within ceramics. I became familiar with commonly overlooked details (which, when ignored, can have disastrous results) and even the problematic idea that ceramics is collectively one subject with a simple set of rules that are easily quantifiable. Many of these conversations have been the foundation on which I have based the presentation of information in this book.

Throughout I have attempted to put across the need to test results ahead of time, not because of a slavish bid for discipline, but in an attempt to encourage experimentation and the honing of ideas alongside a structure. If there is one lesson in ceramics, it is to always give yourself more time to do something than you think.

At the start of my own journey, when I was learning to work with clay, many of the ceramics books I was directed towards used scientific language and cadence, as if it wasnt an artform I was working with but a science. To a person who is of a creative disposition, and interested in arriving at the making as fast as possible, this was frustrating. The presentation of ceramics as a science was not helpful for me at that stage. Having said this, I do know that a deep understanding through these means can be extremely elucidating for many, but at a later stage. At all times during the writing of this book I have attempted to take into account the creative mindset and tried to arrive at each main point as soon as possible.

In order to be as inclusive to all creative perspectives who wish to work with ceramics, I have also chosen to speak about ceramic objects and ceramicists for the majority of the time rather than ware, pottery or potter.

This book aims, for the beginner, to take you through each stage, adding to your knowledge with each subsequent chapter in a way that will be helpful for practical application; it is designed to be read by this type of reader from start to finish for an understanding of electric-kiln firings. For more knowledgeable readers the text can also be used as a reference book to be dipped in and out of as needed.

The firing of kilns will have many factors at play, including external ones affecting the decision-making of the people running them, so some of these considerations are also sometimes discussed in the book. These issues can include anything from ecology, economy, professional deadlines and local politics.

Overall the book has been written to be as understandable as possible with little to no knowledge assumed although, as mentioned above, if coming to this book with little knowledge of kiln firings please take care to read it from the beginning in order to build your knowledge in a way that will make sense of later chapters.

Lastly, all advice in this book should be used in conjunction with the technical specification of the materials you are using, individual manufacturers advice for the equipment and kilns being used, as well as relevant professional advice from electricians and kiln specialists or kiln doctors.

www.jo-davies.com

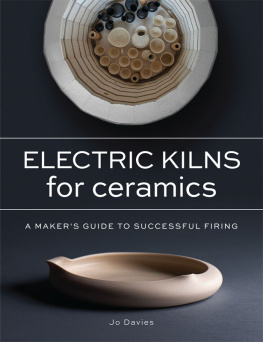

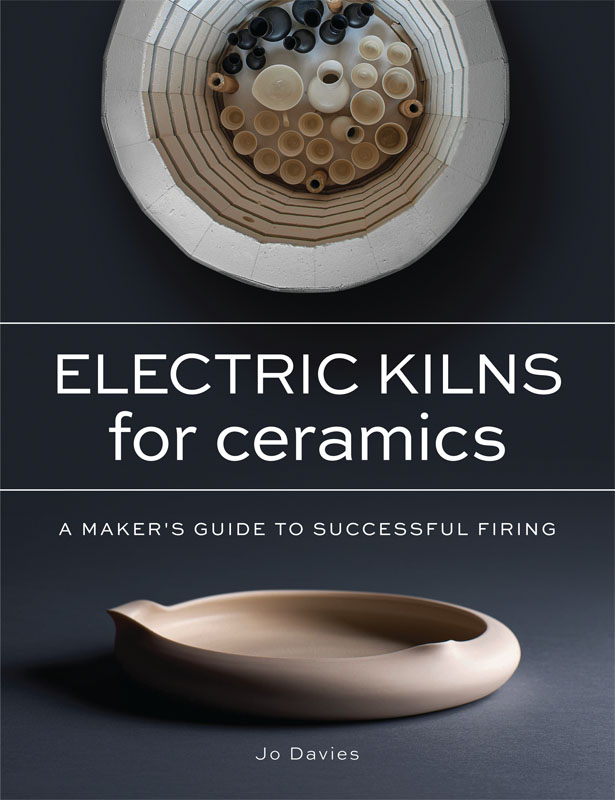

Pouring Bowl by Jo Davies.

CHAPTER 1

WHAT IS A KILN FIRING?

K iln firings is the area of ceramics that all ceramicists have in common. It is a leveller, an area of expertise, nuance, radical approaches and common ground. A ceramicist cannot exist without their kiln or some way of heating their work to a high enough temperature so that the clay they have shaped into existence turns into a hardened ceramic. However, there are some exceptions to this, and I feel it is important to mention artists like Phoebe Cummings, who makes her work with care and attention but then actively encourages it to disintegrate, either with the use of dripping water or by other means, to beautiful effect. However, clay is, for the vast majority of time, dependent on kiln firings to be made permanent and finished.

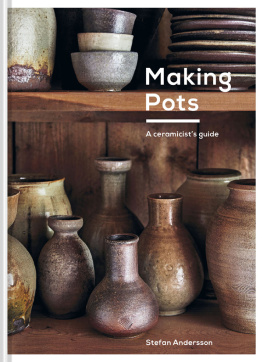

Coral Vases by Jo Davies. High-fired, stained porcelain with black manganese glaze and 24ct goldleaf.

For clay to become ceramic it must be heated, or fired, to above 700C. Although each clay has a slight variation on this and firing this low would result in a very soft, brittle ceramic, this is the temperature at which it changes, at a molecular level, from clay into ceramic. All kiln firings work on the given that everything has a melting point and we are working up to, and sometimes beyond, this point for our chosen materials. Having a knowledge of how our chosen materials will behave at different temperatures is key to developing the kiln firings we use. Thankfully much of the heavy lifting of this has been done for us across generations of ceramic cultural development so the designed, constructed clays we most often use now will give some insight into this information before we begin to work with them.

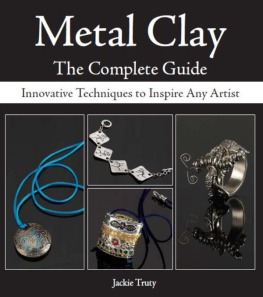

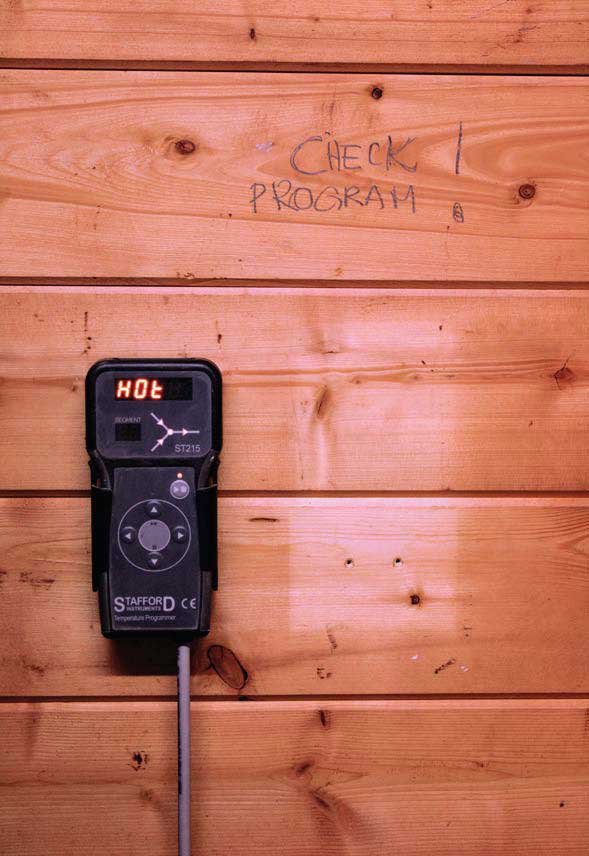

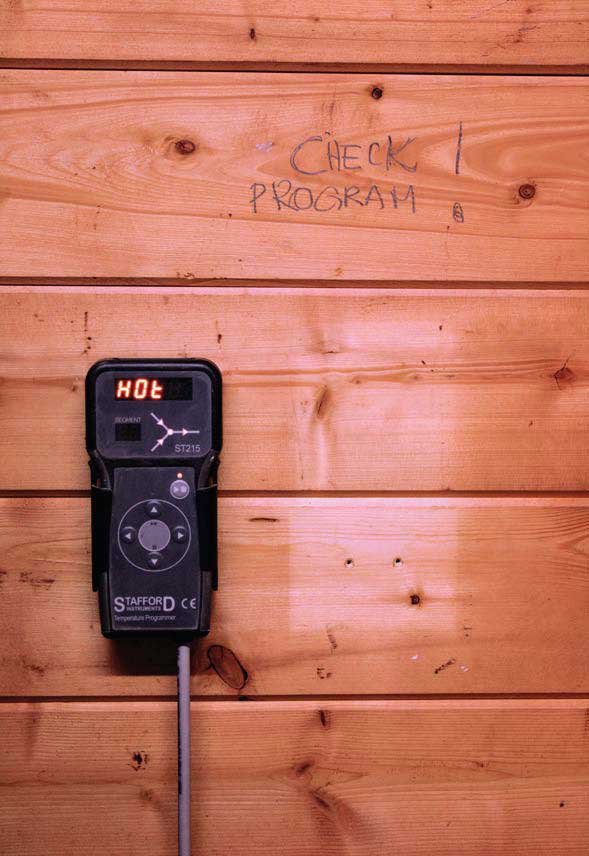

Kiln controller at Katharina Klugs studio.

A kiln is any form of insulated chamber that will allow heat to rise inside it. This can be a permanent structure made from non-flammable materials like brick or stone, or it can be a thickly made structure made from flammable materials like wood. Its walls could also be formed from a simple earth pit or a structure made from engineered firebricks which are either encased for permanence by metal or built and then un-built after each firing for impermanence and flexibility of scale. The different approaches to kilns around the world are many. Cultural differences in kiln technology are visible in the objects that are made by each culture because their tools will reflect the values, tastes and preferences of each indigenous population. Ceramics is no different and, in some ways, through its relative longevity, the field of ceramics is a prime candidate for both a whimsical and utilitarian display of evolving culture.