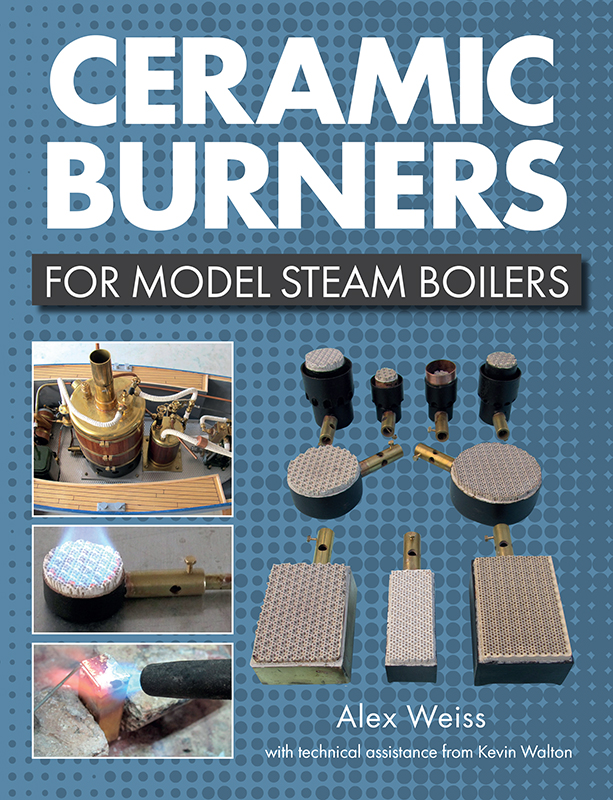

Weiss Alex - Ceramic Burners for Model Steam Boilers

Here you can read online Weiss Alex - Ceramic Burners for Model Steam Boilers full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. publisher: Crowood, genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

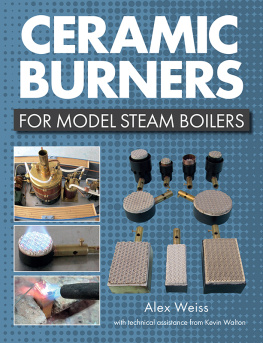

- Book:Ceramic Burners for Model Steam Boilers

- Author:

- Publisher:Crowood

- Genre:

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

Ceramic Burners for Model Steam Boilers: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Ceramic Burners for Model Steam Boilers" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Ceramic Burners for Model Steam Boilers — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Ceramic Burners for Model Steam Boilers" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

CERAMIC

BURNERS

FOR MODEL STEAM BOILERS

CERAMIC

BURNERS

FOR MODEL STEAM BOILERS

Alex Weiss

With technical assistance from Kevin Walton

First published in 2020 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2020

Alex Weiss 2020

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 766 8

DISCLAIMER

Safety is of the utmost importance in every aspect of metalworking. When using tools, always follow closely the manufacturers recommended procedures. However, the author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

Acknowledgements

W HEN I WROTE THE book Building Small Boilers for Gas Firing in 2013, each of the four larger boilers, the three vertical fire-tube ones, and the horizontal water-tube one, was fitted with a commercially available ceramic burner. These burners were either round or rectangular and worked extremely well. They were also quite expensive to purchase.

This led me to wonder whether I could make my own burners with similar dimensions. I discovered that the jewellery trade uses ceramic honeycomb for manufacturing decorative items. This honeycomb material is hard, resists crumbling, and has proved to be ideal for making ceramic burners. Furthermore, the plumbing trade provides a large variety of end caps that are suitable for use as housings for all the circular burners, together with the occasional length of copper tube. All the burners need short lengths of brass rod for the gas-jet holders and housings, and the rectangular burners require small flat sheets of copper or brass, widely available from the suppliers to model engineers. The success of these designs led to the production of some even smaller burners, suitable for Mamod, Wilesco and similar-size small boilers.

I must thank my friend Kevin Walton, who has provided much of the technical input and detailed recommendations that have made possible the building of the burners described in this book. He has also helped with the construction of all the burners, and has solved some significant problems relating to how they were built and in their operation.

Finally, I must mention my appreciation of my wife Lynda, who has had to put up with all the work involved in making the burners, testing and photographing them, as well as the many months writing up and organizing the results on my computer.

Introduction

H EAT HAS ALWAYS BEEN an essential for humans. Its earliest use was in the form of wood fires used to keep warm and to cook food. For some people, oil or tar emerged from the surface of the ground and was also found to burn well. It was particularly useful for providing torchlight at night. The first steam-powered device dates back to ancient Greek times, but it wasnt until the start of the industrial revolution that useful work was obtained from steam engines.

There is something incredibly appealing about operating model steam engines. They may require a heat source and a boiler to generate the steam, but they produce almost silent power, normally without the need for gear changes to drive their load. And they are a glorious reminder of the golden age of the industrial revolution.

Steam engines, as originally envisaged by Newcomen, Trevithick, Watt and others, have become the life blood of many preservation organizations, but the steam turbine, invented by Charles Parsons, is still happily turning the generators in power stations that produce electricity, as well as propellers in some ships. The steam generators for these turbines may be heated by coal, gas, oil or a controlled nuclear chain reaction.

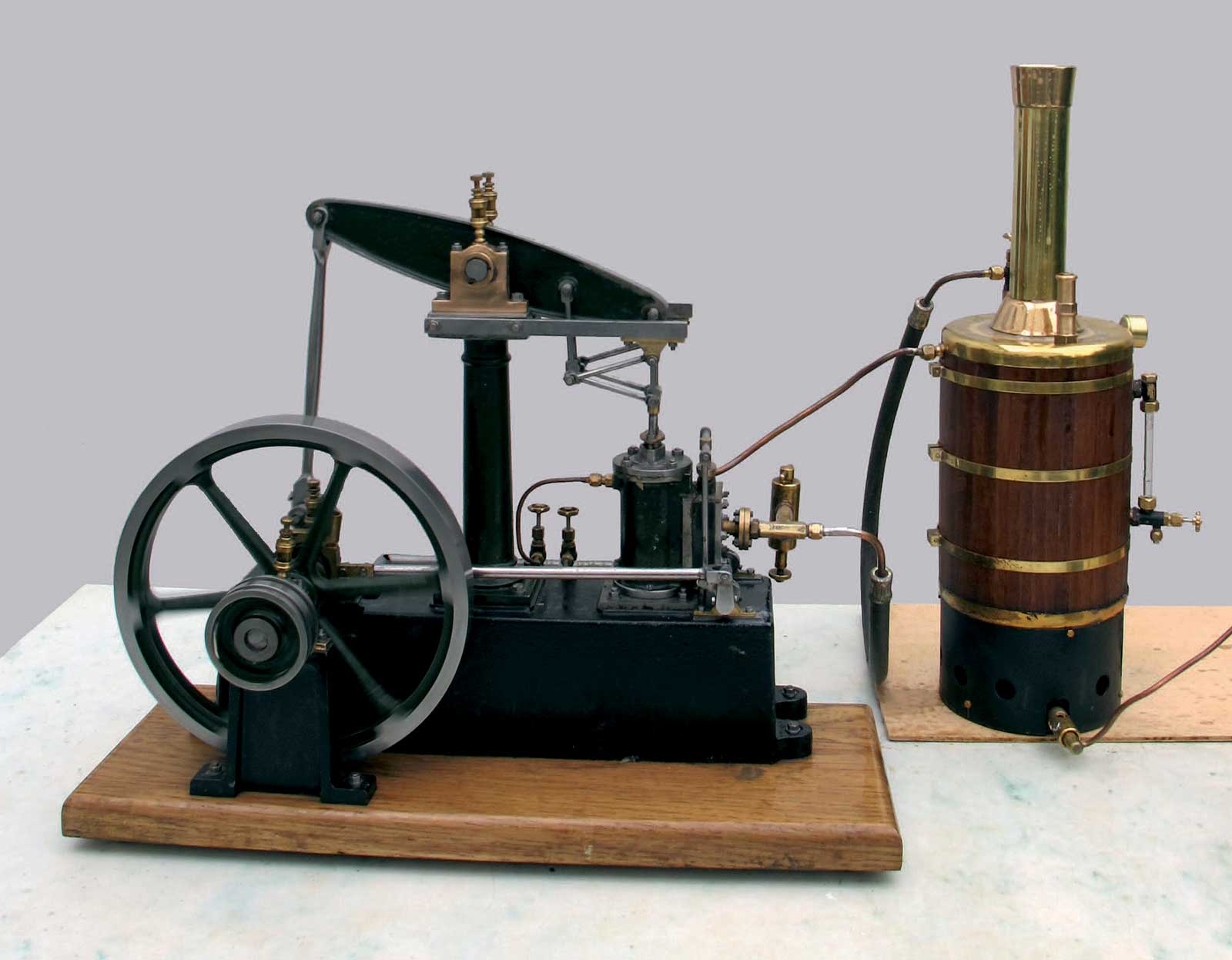

FIG. 1

A Stuart beam engine powered by a 108mm (414in) vertical fire-tube boiler heated by a 67mm round ceramic burner.

FIG. 2

A 76mm (3in) horizontal water-tube boiler fitted with a 70 50mm rectangular burner steaming a single-cylinder mill engine.

Running a model steam engine on compressed air is neither good for the engine nor in any sense realistic. Running on steam from the right size of model boiler is exhilarating, and with a displacement lubricator, feeds small amounts of oil through the valves into the cylinder to minimize wear to the valve gear and on the cylinder/piston combination.

There are many ways of heating the water in a model steam boiler. They include using coal, liquefied petroleum gas (LPG), paraffin, methylated spirits, impregnated pellets and historically petrol, although petrol is not considered a safe option in the twenty-first century. This is because petrol vapour is explosive, and as a result, using a petrolfuelled blowlamp to heat a boiler has, fortunately, all but disappeared.

Each source of heat comes with its own set of problems. With coal, the fire requires a stoker, normally human, to add coal regularly to the firebox. Starting the fire with kindling can also be a time-consuming task. On the other hand, LPG gives a virtually instantaneous heat and can provide a high heat output. However, it does require a safe gas tank and care in handling the gas. Paraffin or kerosene is not a very volatile liquid and is difficult to vaporize ready for burning. Methylated spirits will produce relatively small amounts of heat, and again will require a safe spirit container. The flame is virtually invisible and the storage tank must be protected from the heat.

However, neither methylated spirits nor LPG need an operator in attendance. They are thus suitable for installation in model vehicles and steam boats but take care to ensure the heat source is exhausted before the boiler water has run out. The same warning applies to stationary installations. A boiler that has run out of water is readily destroyed if the heating is not turned off.

Over the past ten years, the author and Kevin Walton have designed and built nine different boilers of a variety of shapes, sizes and configurations, but all within the 3-bar litre limit detailed in the UK Boiler Test Code 2018 Volume 2. Some years ago Building Small Boilers for Gas Firing was published by Camden Miniature Steam Services, giving detailed instructions on how to build these boilers. The majority of the boilers were heated by commercial ceramic burners, but some subsequent experiments led to fitting new home-made burners to most of these boilers, and writing about how to make the burners in a typical model engineers workshop, and also how to operate these burners.

Font size:

Interval:

Bookmark:

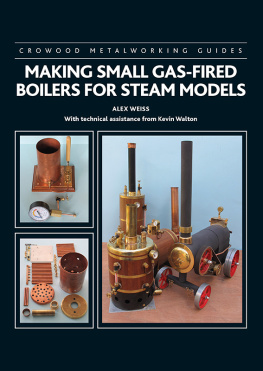

Similar books «Ceramic Burners for Model Steam Boilers»

Look at similar books to Ceramic Burners for Model Steam Boilers. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Ceramic Burners for Model Steam Boilers and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.