Page List

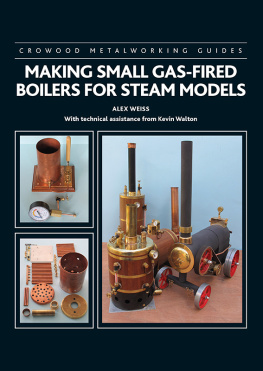

CROWOOD METALWORKING GUIDES

MAKING SMALL GAS-FIRED

BOILERS FOR STEAM MODELS

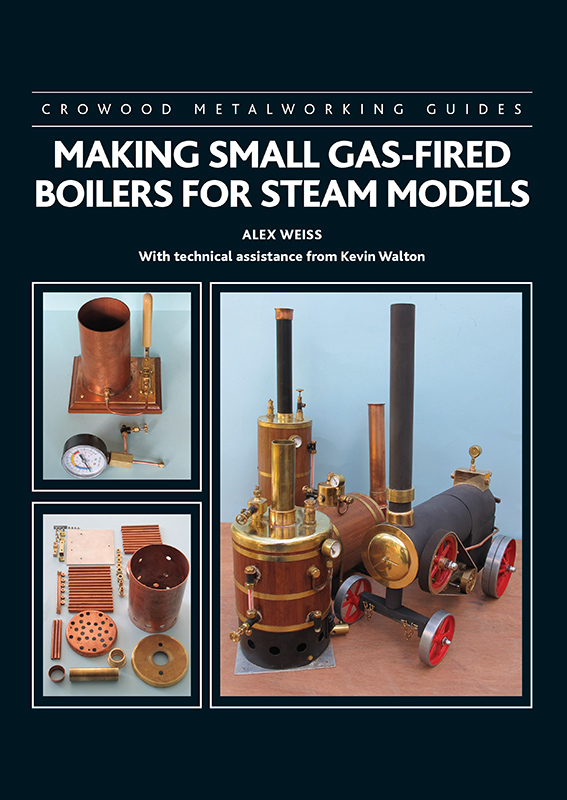

There is comprehensive information in this book that explains how to build all four of these boilers.

CROWOOD METALWORKING GUIDES

MAKING SMALL GAS-FIRED

BOILERS FOR STEAM MODELS

ALEX WEISS

With technical assistance from Kevin Walton

First published in 2021 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2021

The Crowood Press 2021

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 877 1

Disclaimer

Safety is of the utmost importance in every aspect of metalworking. The practical workshop procedures and the tools and equipment used in metalworking are potentially dangerous. Tools should be used in strict accordance with the manufacturers recommended procedures and current health and safety regulations. The author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

Cover design: Maggie Mellett

Acknowledgements

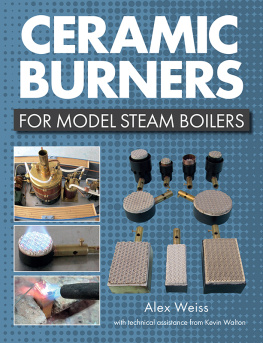

Much of this book was written during the coronavirus pandemic and covers four boilers that I built together with my friend, Kevin Walton; fortunately not during the UK lockdown. These boilers all meet the UK three-bar litre requirements of the UK 2018 Boiler Test Code 2018 Volume 2. All four are heated by ceramic burners, again built by Kevin and myself, although you can just as easily heat them with commercially purchased ceramic burners.

It is pretty clear that when the pandemic comes to an end, the market place, including the model engineering one, is likely to have changed. Some businesses will have prospered; sadly some will have ceased trading. In addition, global trading arrangements and exchange rates will inevitably have changed, affecting the price of many of the materials and finished items we purchase. For those who use eBay for purchasing parts for model engineering, try and use suppliers you have bought from before. Particularly for more expensive items, take great care if you have not used the company before and do your best to check their reputation. And those of us who may continue to work from home will find that we have more spare time that was previously spent commuting to and from work. We will all have to do our best to benefit from the changing environment.

I must thank Kevin Walton, who has provided much of the technical input and detailed recommendations, also making parts and helping with the assembly, which have made possible the building of the boilers that I have described in this book. He has also helped solve some significant issues about how best to design them and build them.

Finally, I must mention my wife Lynda, who daily has had to put up with all the time I spend in my workshop, Kevins workshop, building, testing, running and photographing the boilers from kits of parts to completed items. Inevitably this is followed by months writing up and organizing the results on my computer ready for publication by the friendly staff at The Crowood Press.

It goes without saying that any errors in this book are mine and mine alone.

Introduction

For millennia after human beings first harnessed horses and other beasts of burden, the ability to power machines and move people and goods remained very limited. Goods were transported on land by horse and cart, while at sea wind power or men rowing were the only choices. Early water mills were built by the Greeks and Romans over 2,000 years ago to grind grain. Later, the first windmills were built to assist in making flour and pumping water for crop irrigation.