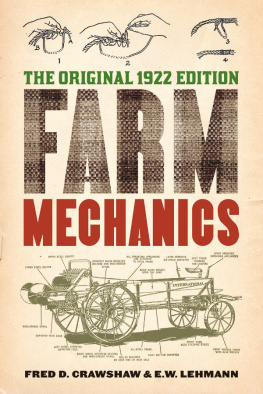

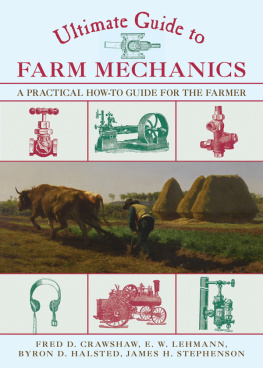

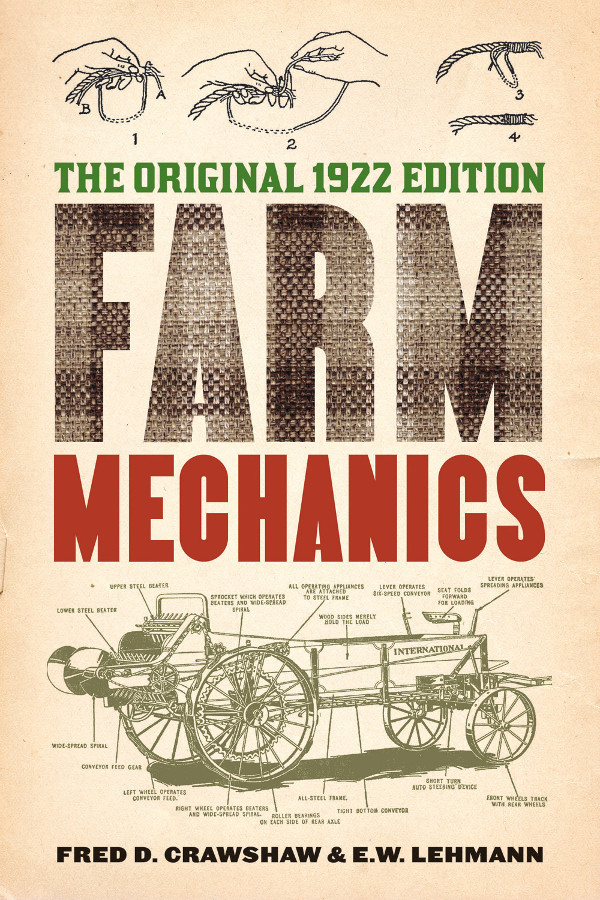

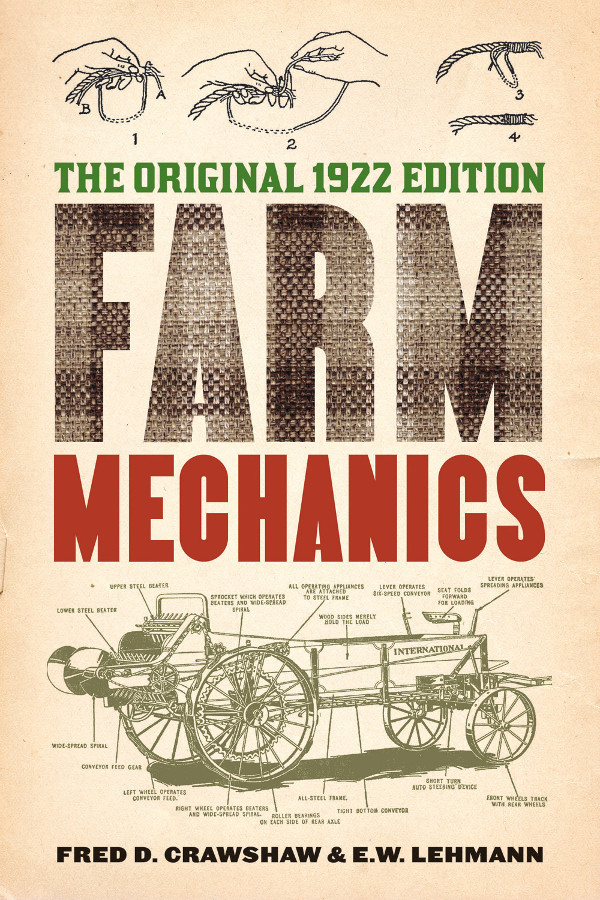

FARM MECHANICS

FARM MECHANICS

by

FRED D. CRAWSHAW

Formerly Professor of Manual Arts,

University of Wisconsin

and

E. W. LEHMANN

Professor of Farm Mechanics,

University of Illinois

Copyright 2012 by Skyhorse Publishing

No claim is made to material contained in this work that is derived from government documents. Nevertheless, Skyhorse Publishing claims copyright in all additional content, including, but not limited to, compilation copyright and the copyright in and to any additional material, elements, design, or layout of whatever kind included herein.

All Rights Reserved. No part of this book may be reproduced in any manner without the express written consent of the publisher, except in the case of brief excerpts in critical reviews or articles. All inquiries should be addressed to Skyhorse Publishing, 307 West 36th Street, 11th Floor, New York, NY 10018.

Skyhorse Publishing books may be purchased in bulk at special discounts for sales promotion, corporate gifts, fund-raising, or educational purposes. Special editions can also be created to specifications. For details, contact the Special Sales Department, Skyhorse Publishing, 307 West 36th Street, 11th Floor, New York, NY 10018 or .

Skyhorse and Skyhorse Publishing are registered trademarks of Skyhorse Publishing, Inc., a Delaware corporation.

Visit our website at www.skyhorsepublishing.com.

10 9 8 7 6 5 4 3 2 1

Library of Congress Cataloging-in-Publication Data is available on file.

ISBN: 978-1-62087-059-4

Printed in the United States of America

FARM MECHANICS

PREFACE

T HIS book has been prepared to meet the increasing need for a textbook on the mechanical processes commonly taught in agricultural high schools and colleges, and in industrial schools. Many teachers of vocational agriculture who find it difficult to organize suitable projects for their students will find that the exercises in this text have been worked out to meet their needs. The book should also be widely useful as a reference and instruction book on the farm.

The types of work covered, while primarily representing the common branches of mechanical activity required under rural conditions, are, in most cases, applicable to the requirements of the industry upon which each type has a bearing.

Each part of the book deals exclusively and comprehensively with one particular type of work, as woodwork, cement work, forging, etc.; a fact which should contribute to its usefulness, both as a text and as a reference book. Thru further divisions into chapters and numbered topics, a greater possibility of locating, at any time, the various details and descriptions is offered.

The treatment thruout the book is thoroly practical. Emphasis is placed upon the proper use of tools and materials in their application to projects. The projects are selected from the standpoint of the practical application to the needs of the student. The gradation of projects within each of the parts has been kept in mind. The plan has been to treat each topic in such detail that the teacher who has a variety of mechanical work going on in his classes at one time may be largely relieved of the burden of class instruction, and can devote his energies to the needs of the individual pupil. Working drawings and specifications for many of the projects have been given. Each of these projects is analyzed into its sequential operations with numerous references to the previous projects for specific details. Many supplementary projects are provided.

The authors are indebted to their many friends who have given freely of their material and advice. They wish particularly to acknowledge the use of material furnished by the University of Illinois, the University of Missouri, the Iowa State College, the Portland Cement Association, and of cuts furnished by several trade journals and taken from state bulletins.

FEED D. CRAWSHAW.

E. W. LEHMANN.

CONTENTS

PART I

WOODWORKING

1. Logging. 2. Milling. 3. Tree growth. 4. Seasoning. 5. Meas-urements and calculations. 6. Trees.

7. Classification.

8. Saws used. 9. Rip-saws. 10. Crosscut-saws. 11. Rip-sawing. 12. Squaring and measuring for length. 13. Gaging for width. 14. Marking fan strips. 15. Boring holes. 16. Sawing ends. 17. Ripping off one-half-inch strip. 18. Ripping tapered edges. 19. Ripping for fan strips. 20. The buggy axle rest and the measuring crate. 21. The bevel square. 22. Nailing.

23. The plane. 24. Care of plane-irons. 25. Grinding the plane-iron. 26. Whetting the plane-iron. 27. Care of plane. 28. Use of the plane. 29. Face side. 30. Joint edge. 31. Second edge. 32. Second surface. 33. First end. 34. Second end. 35. Boring holes for rope. 36. Sawing end notches.

37. Calculations of stock. 38. Roof boards. 39. Fastening front strips. 40. Fastening back boards. 41. Trimming. 42. Checking estimate.

43. Tools, 44. Preliminary instruction. 45. Purpose of seed tester. 46. Rough cutting. 47. Laying out. 48. Sawing. 49. Chiseling joints. 50. Fastening corners. 51. Nailing bottom. 52. Marking edges. 53. Supplementary instructions. 54. Special operations.

55. Modeling tools. 56. Squaring the stock; laying out. 57. Using the turning-saw. 58. Use of the spoke-shave. 59. Scraping and sandpapering. 60. The wood rasp. 61. The shoulder carrier.

62. Sheep rack and feed bunk. 63. Directions for woodworking bench. 64. Working directions for dog house. 65. Directions for corn drier. 66. Making the self-feeder. 67. Making the egg tester. 68. Constructing a cow stanchion. 69. Making tomato trellis. 70. Feed bunk for cattle. 71. Saw buck. 72. Chicken feeder. 73. Garden marker. 74. Individual hog cot. 75. Feed bunk for sheep. 76. Plow doubletree. 77. Wagon jack. 78. Heavy farm sled. 79. Fence post mold.

80. Purpose of wood-finishing. 81. Method of preservation. 82. Classification of wood finishes. 83. Oil stain. 84. Wax. 85. Water stains. 86. Oil stains; chemical stains. 87. Coal-tar creosote oil. 88. The brush method. 89. The open-tank process. 90. Shellac. 91. Varnish. 92. Wood-filler. 93. Paint.

94. Definition. S5. Precautions. 96. Cutting glass. 97. Setting a pane of glass in a new frame. 98. Applying the putty. 99. Screening.

PART II

CEMENT AND CONCRETE

100. Preliminary. 101. Pre-historic uses of concrete. 102. Rediscovery of cement. 103. Natural cement in America. 104. Portland cement.

CHAPTER XII. PROPERTIES AND USES OF CEMENT

105. Properties. 106. Mortar. 107. Definition of concrete. 108, Aggregates. 109. Presence of rotten or soft pebbles in the gravel. 110. Presence of dirt in the aggregate. 111. Vegetable matter in sand.

112. Proportions. 113. Requirements of good concrete. 114. Standard mixtures. 115. Common errors in proportioning concrete. 116. Determining quantities for a job. 117. Requirements of good mixing. 118. Hand-mixing. 119. Procedure in hand-mixing. 120. Machine-mixing. 121. Consistency of mixtures. 122. Placing of concrete. 123. Three methods of placing concrete. 124. Handling concrete.

125. Necessity of forms. 126. Importance of form construction. 127. Earth forms. 128. Cast, wrought or galvanized iron forms. 129. Wood forms. 130. Requirements of a good form. 131. Use of old lumber for forms. 132. Sharp corners in forms. 133. Removing forms; care of forms.

134. The principle of reinforcing. 135. Compression and tension in beams. 136. Kinds of reinforcing. 137. Use of scrap iron for reinforcing concrete. 138. Tools for concrete work.

Next page