Copyright

Butterworth-Heinemann is an imprint of Elsevier

The Boulevard, Langford Lane, Kidlington, Oxford OX5 1GB, United Kingdom

50 Hampshire Street, 5th Floor, Cambridge, MA 02139, United States

Copyright 2023 Elsevier Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publisher's permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

ISBN: 978-0-443-18995-1

For information on all Butterworth-Heinemann publications visit our website at https://www.elsevier.com/books-and-journals

Publisher: Matthew Deans

Acquisitions Editor: Chiara Giglio

Editorial Project Manager: Mason Malloy

Production Project Manager: Fizza Fathima

Cover Designer: Matthew Limbert

Typeset by STRAIVE, India

Chapter 1: Introduction

Abstract

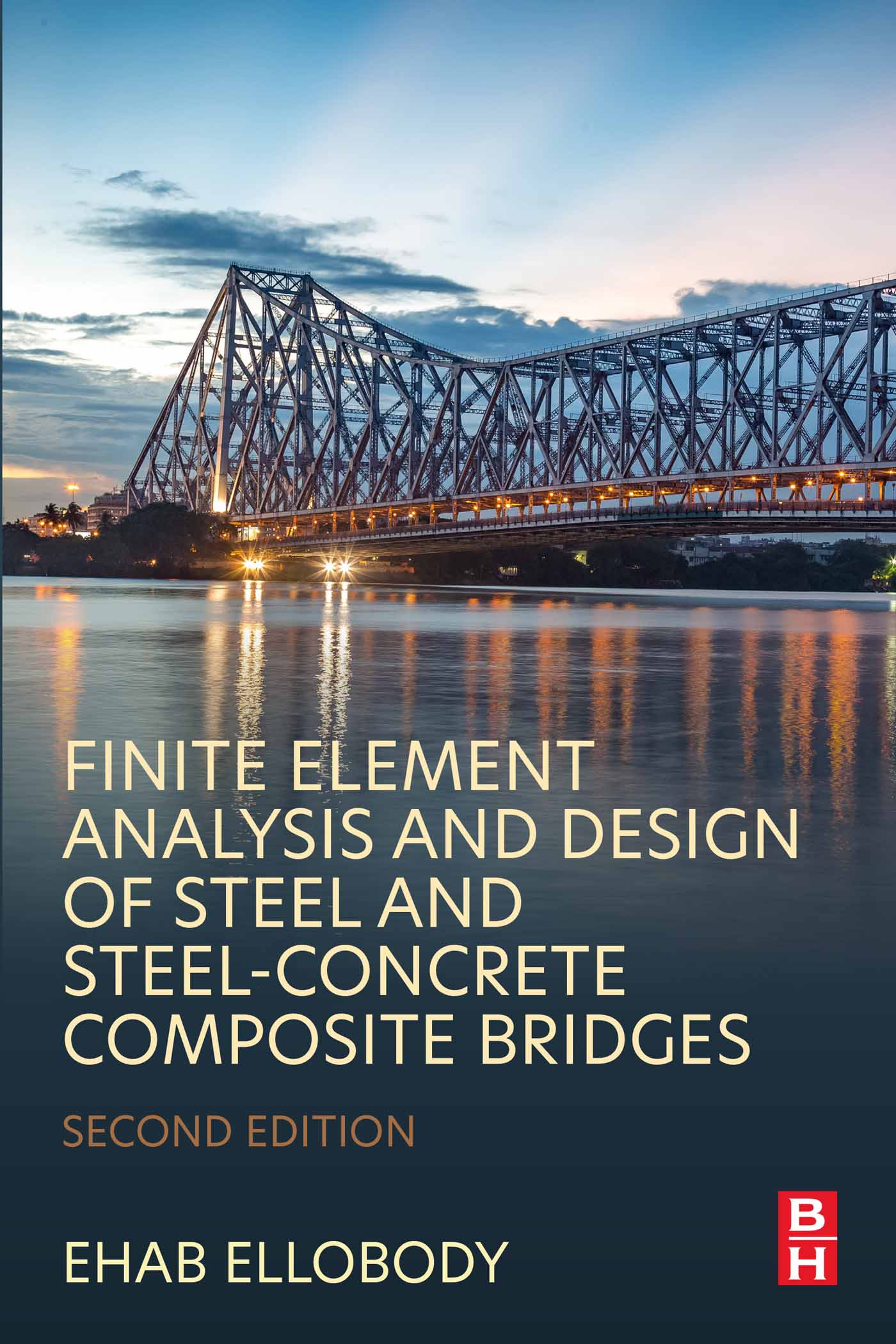

Steel and steel-concrete composite bridges are commonly used all over the world because they combine both magnificent esthetic appearance and efficient structural competence. Numerous books were found in the literature highlighting different aspects of design for steel and steel-concrete composite bridges. However, up-to-date, the only detailed book found in the literature addressing both finite element analysis and design of steel and steel-concrete composite bridges is credited to the first edition of this book. This book highlights the use of finite element modeling to improve and propose more accurate design guides for steel and steel-concrete composite bridges, which are rarely found in the literature. The book consists of eight well-designed chapters covering necessary topics related to finite element analysis and the design of steel and steel-concrete composite bridges. This chapter provides a general background for the types of steel and steel-composite bridges. extends the approach of combining design with finite element modeling, adopted in the first edition of this book, to cover composite highway bridges with profiled steel sheeting.

Keywords

Steel-concrete composite bridges; Steel bridges; Railway and highway bridges; Finite element modeling; Design approach; Full-scale testing simulation

1.1: General remarks

Steel and steel-concrete composite bridges are commonly used all over the world because they combine both magnificent esthetic appearance and efficient structural competence. Their construction in a country not only resembles the vision and inspiration of their architects but also represents the country's existing development and dream of a better future. Compared to traditional reinforced concrete (RC) bridges, steel bridges offer many advantages, comprising high strength-to-self weight ratio, speed of construction, flexibility of construction, flexibility to modify, repair and recycle, durability, and artistic appearance. The high strength-to-self weight ratio of steel bridges minimizes dead loads of the bridges, which is particularly beneficial in poor ground conditions. Also, the high strength-to-self weight ratio of steel bridges makes it easy to transport, handle, and erect the bridge components. In addition, it facilitates very shallow construction depths, which overcome problems with headroom and flood clearances, and minimizes the length of approach ramps. Furthermore, high strength-to-self weight ratio of steel bridges permits the erection of large components, and in special circumstances, complete bridges may be installed in quite short periods. The speed of construction of steel bridges is attributed to the fact that most of the bridge components can be prefabricated and transported to the construction field, which reduces working time in hostile environments. The speed of construction of steel bridges also reduces the duration of road closures, which minimizes disruption around the area of construction. The flexibility of the construction of steel bridges is attributed to the fact that the bridges can be constructed and installed using different methods and techniques. Installation may be conducted by cranes, launching, slide-in techniques, or transporters. Steel bridges give contractors the flexibility in terms of erection sequence and program. The bridge components can be sized to suit access restrictions at the site, and once erected, the steel girders provide a platform for subsequent operations. The flexibility to modify, repair, and recycle steel bridges is a result of the ability to modify the current status of the bridges such as widening the bridges to accommodate more lanes of traffic. Also, steel bridges can be repaired or strengthened by adding steel plates or advanced composite laminates to carry more traffic loads. In addition, if for any reason, such as the end of their life of use or change of environment around the area, steel bridges can be recycled. Steel bridges are durable bridges, provided that they are well-designed, properly maintained, and carefully protected against corrosion. Finally, steel bridges can fit most of the complex architecture designs, which in some cases are impossible to accommodate using traditional RC bridges.

Highway bridges made of RC slabs on top of the steel beams can be efficiently designed as composite bridges to get the most benefit from both the steel beams and concrete slabs. Steel-concrete composite bridges offer additional advantages to the aforementioned advantages of steel bridges. Compared to steel bridges, composite bridges provide higher strength, higher stiffness, higher ductility, higher resistance to seismic loadings, full usage of materials, and particularly higher fire resistance. However, these advantages are maintained, provided that the steel beams and concrete slabs are connected via shear connectors to transmit shear forces at the interface between the two components. This will ensure that the two components act together in resisting applied traffic loads on the bridges, which will result in significant increases in the allowable vehicular weight limitations, the ability to transport heavy industrial and construction equipment, and the possibility to issue overload permits for specialized overweight and oversized vehicles. One of the main advantages of having steel beams acting together with concrete slabs in composite bridges is that premature possible failures of the two separate components are eliminated. For example, one of the primary modes of failure for concrete bridges is cracking of the concrete slabs and beams in tension, while for the steel bridges, the possible modes of failure are the formation of plastic hinges and the buckling of webs or flanges. By having the steel beams work together with the concrete slab, the whole slab will be mainly subjected to compressive forces, which reduces the possibility of tensile cracking. On the other hand, the presence of the concrete slab on top of the steel beams eliminates the buckling of the top flange of the steel beams. The efficient design of steel-concrete composite bridges can ensure that both the steel beams and concrete slabs work together in resisting applied traffic loads until failure occurs in both components, preferably at the same time, to get the maximum benefit from both components.